Wind wheel cable-stayed structure of wind driven generator with vertical shaft

A wind turbine, vertical axis technology, applied to wind turbines, wind turbines at right angles to the wind direction, motors, etc., can solve the problems of reduced generator service life, unstable operation of wind rotors, and reduced efficiency, and achieve reduced design The effect of manufacturing cost, increased running stability, and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

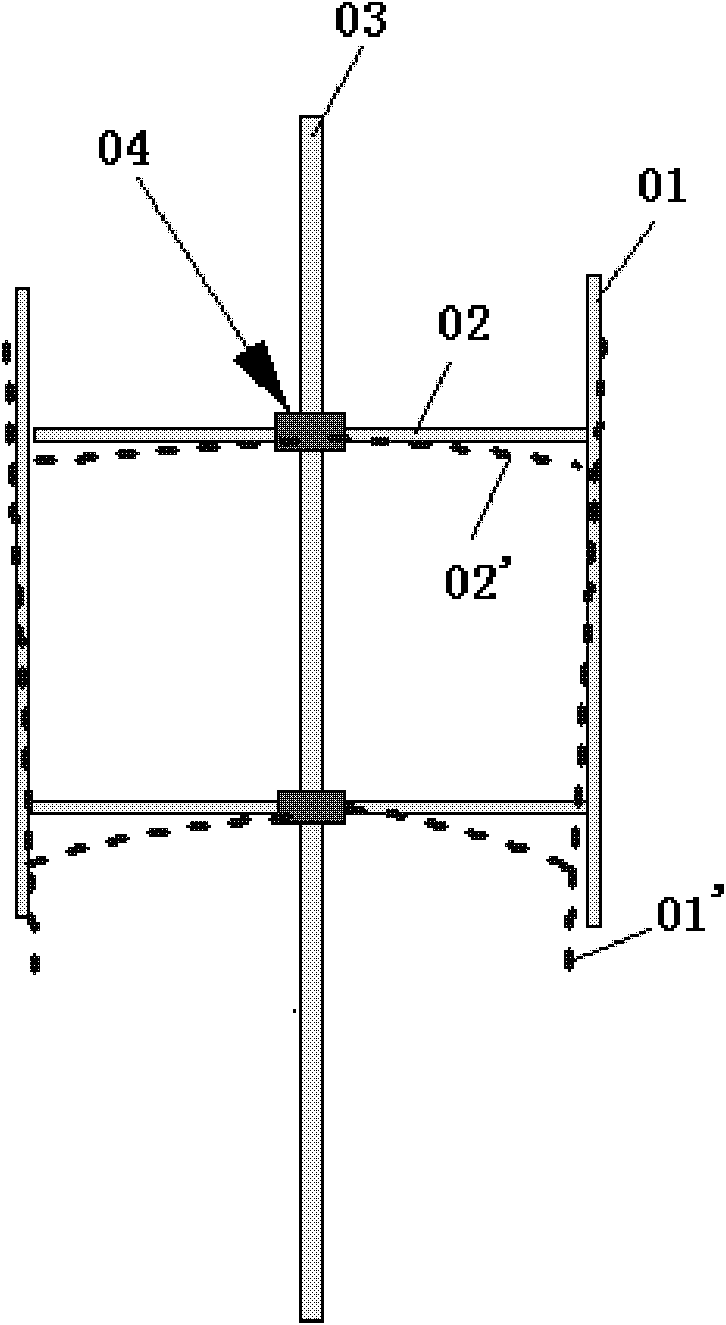

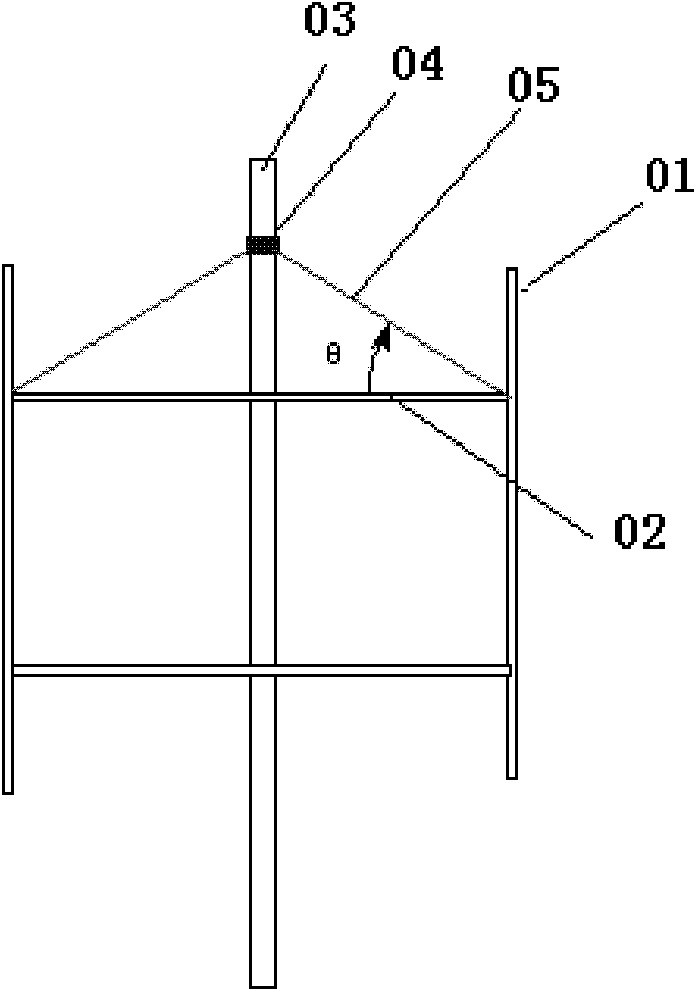

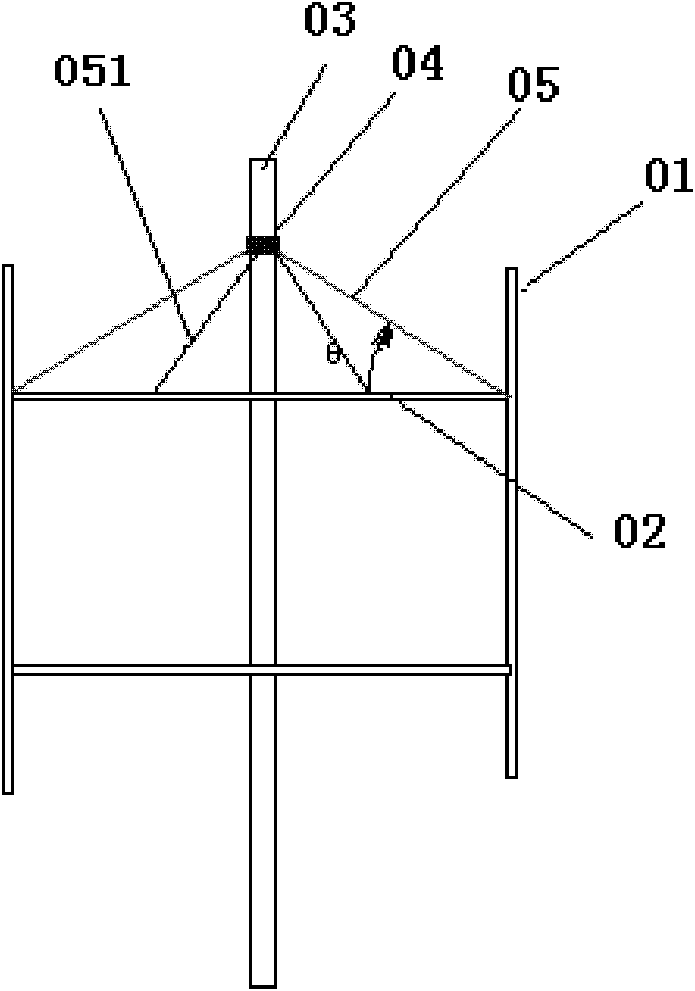

[0037] Such as figure 2 As shown, a wind wheel cable-stayed structure of a vertical axis wind power generator, wherein a wind wheel is arranged on a tower column 03 of the vertical axis wind power generator, and the wind wheel includes blades 01 and support bars 02, and several support bars 02 One end is fixed on the external rotor 06 of the generator set on the tower column 03, and the other end is fixed on the inner side of the columnar vertically arranged blade 01; the cable-stayed structure includes a cable-stayed bearing 04 and a cable 05; The cable-stayed bearing 04 is sleeved and fixed on the tower column 03 above the external rotor 06 of the generator. One end of the cable-stayed bearing 05 is connected to the external rotating part of the cable-stayed bearing, and the other end is connected to the external rotor 06 of the generator. The blades or support rods are connected. In this embodiment, the stay cables are connected to the connection points of the blade 01 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com