Printed label tape and manufacturing method thereof

A production method and technology of trademark tapes, which are applied to dry-cleaning fiber products, textiles, fabrics, etc., can solve the problems of trademark fading, poor production technology, and containing harmful substances to the human body, and achieve low production costs and improved solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

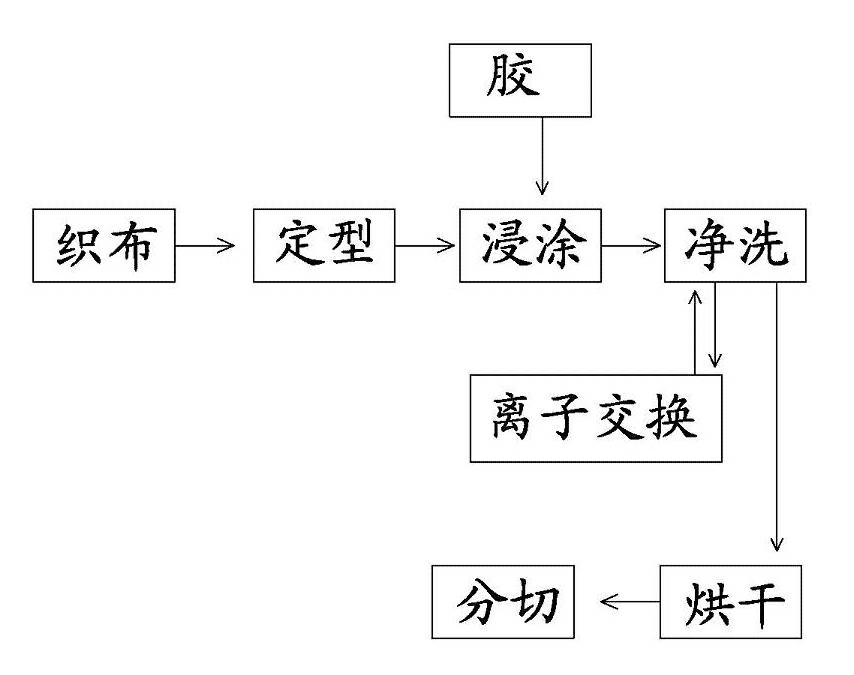

Image

Examples

Embodiment 1

[0039] A printed trademark tape, which includes a gray cloth layer 1 and a glue layer 2, the thickness of which is 125 μm, and the thickness of the gray cloth layer is 120 μm; its residual chloride ion content is less than or equal to 1.28%.

[0040] The manufacturing method of the above-mentioned printed trademark tape is as follows:

[0041] ①Choose waste nylon yarn, then pick out the non-nylon components, and then mix magnesium chloride and magnesium sulfate to dissolve in toluene to make glue for dipping the grey cloth. The specific component distribution ratio of the glue is as follows:

[0042] Nylon 10wt%

[0043] Magnesium sulfate 10wt%

[0044] Magnesium chloride 10wt%

[0045] Toluene 70wt%

[0046] ②After the nylon grey cloth is cleaned, immerse it in the above glue to apply glue to the grey cloth. The amount of glue applied is controlled to 25g / m 2 ;

[0047] ③The coated cloth obtained by gluing treatment is cleaned in dechlorinated water at a temperature of 20~30℃, and the was...

Embodiment 2

[0050] A printed trademark tape, which includes a gray cloth layer 1 and a glue layer 2, the thickness of which is 130 μm, and the thickness of the gray cloth layer is 125 μm; its residual chloride ion content is ≤1.34%.

[0051] The manufacturing method of the above-mentioned printed trademark tape is as follows:

[0052] ①Choose waste nylon yarn, then pick out the non-nylon components, and then mix calcium chloride and calcium sulfate to dissolve in butyl acrylate to make a glue for dipping the grey cloth. The specific composition of the glue is such as under,

[0053] Nylon 12wt%

[0054] Calcium sulfate 12wt%

[0055] Calcium chloride 12wt%

[0056] Butyl acrylate 64wt%

[0057] ②After the nylon grey cloth is cleaned, immerse it in the above glue to apply glue to the grey cloth. The amount of glue applied is controlled to 28g / m 2 ;

[0058] ③The coated cloth obtained by gluing treatment is cleaned in dechlorinated water at a temperature of 20~30℃, and the washing time is 5~10min; the ...

Embodiment 3

[0061] A printed trademark belt, which includes a gray cloth layer 1 and a glue layer 2, its thickness is 135 μm, and the thickness of the gray cloth layer is 130 μm; its residual chloride ion content is less than or equal to 1.39%.

[0062] The manufacturing method of the above-mentioned printed trademark tape is as follows:

[0063] ①Choose waste nylon yarn, then pick out the non-nylon components in it, then mix magnesium chloride and calcium carbonate to dissolve in methanol to make glue for dipping the grey cloth. The specific component distribution ratio of the glue is as follows:

[0064] Nylon 13wt%

[0065] Calcium carbonate 13wt%

[0066] Magnesium chloride 13wt%

[0067] Methanol 61wt%

[0068] ②After the nylon grey cloth is cleaned, immerse it in the above glue to apply glue to the grey cloth. The amount of glue is controlled to 30g / m 2 ;

[0069] ③The coated cloth obtained by gluing treatment is cleaned in dechlorinated water at a temperature of 20~30℃, and the washing time is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com