Method and tool for machining rod-shaped reconstructed wood unit

A technology for processing knives and processing methods, which is applied in the direction of wood processing appliances, manufacturing tools, and processing machines for manufacturing flat surfaces, etc. It can solve the problems of high processing energy consumption, large amount of glue, and unsatisfactory bonding strength, etc., and achieve processing efficiency. High, high bonding strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with drawings and embodiments.

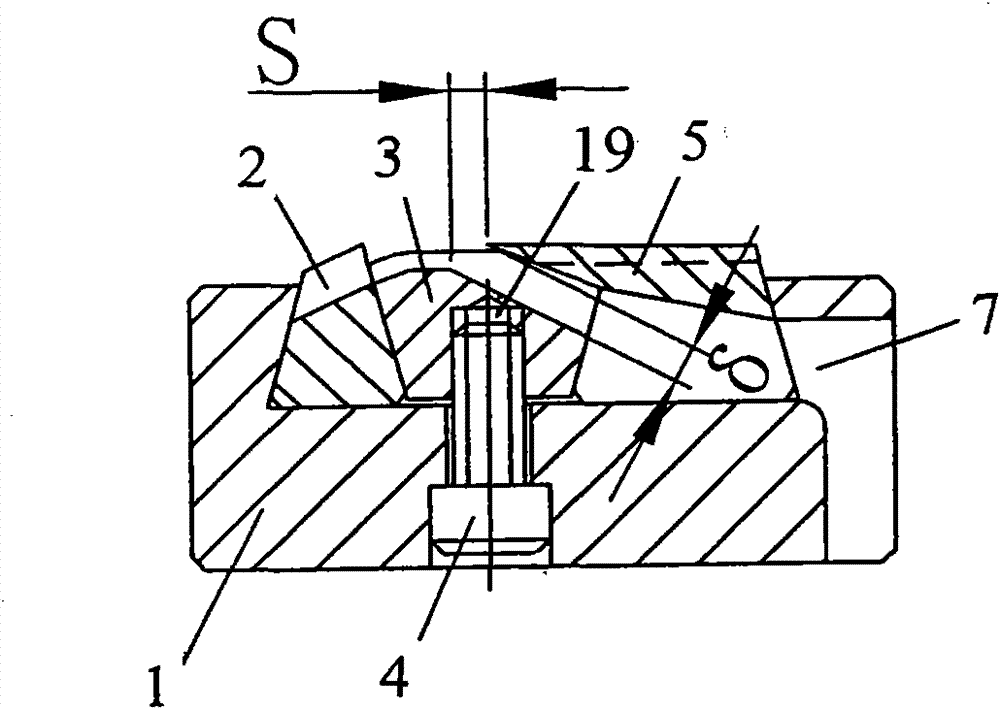

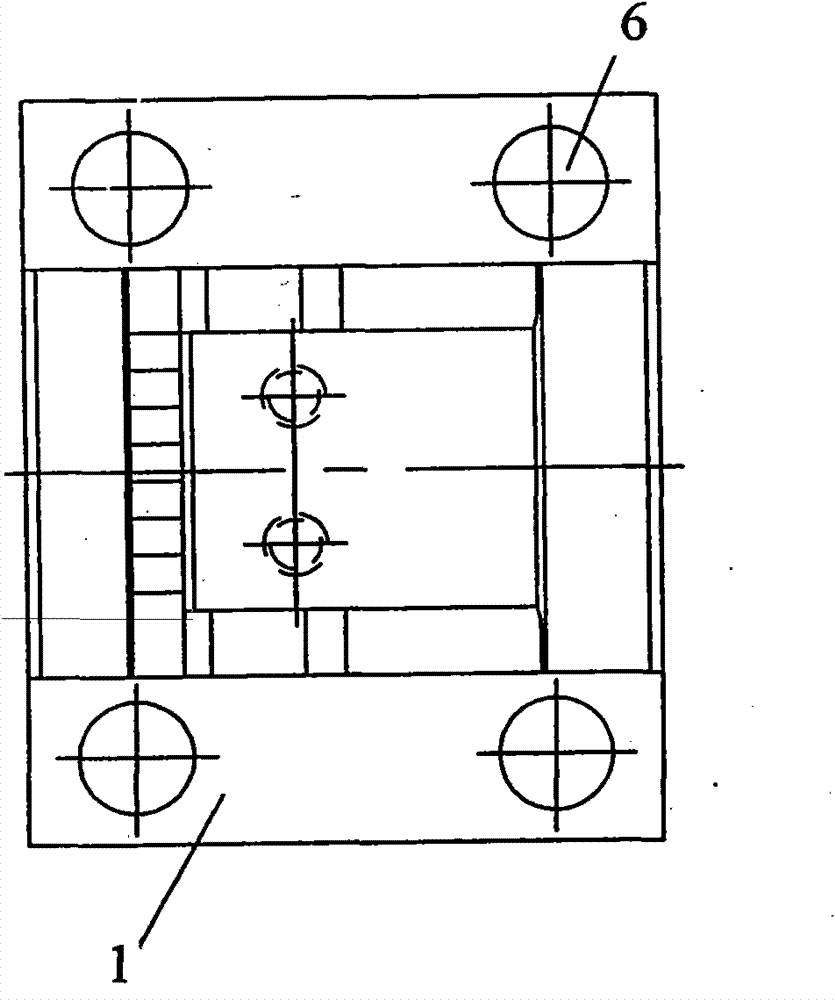

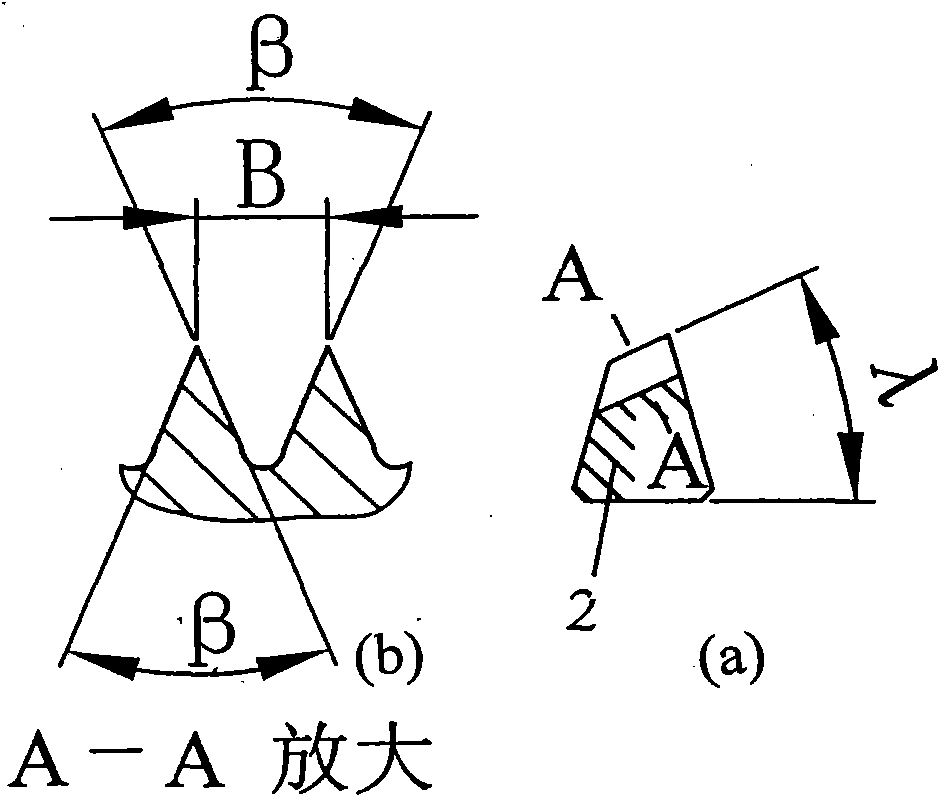

[0029] Such as figure 1 , figure 2 As shown, the combined tool for processing wood screw rods consists of a base 1, a scratcher 2, a briquetting block 3, a fixing screw 4, and a planer 5. Such as Figure 5 , the base 1 has four installation holes 6, the middle boss has a dovetail groove, and one side of the dovetail groove has a rectangular channel 7 as the discharge port of the wood screw. There is a scratcher 2 inside, and the pressing block 3 installed between the scratcher 2 and the planer 5 is fixed by the fixing screw 4. The pressing block 3 fixes the scratcher 2 and the planer 5 on both sides of the dovetail groove, and the scraper blade 12 and the planer blade 15 is higher than the top surface of the boss in the middle of the base 1. Such as image 3 , Figure 6 , Figure 7 , two sides of the long side of the knife 2 and the bottom surface form two equal...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap