Composite material mechanical arm and manufacture method thereof

A technology of composite materials and manipulators, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of heavy weight and inability to meet the use requirements of precise transmission, achieve good damping performance, solve manual unloading difficulties, and resist The effect of damping properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: The structure of a composite material manipulator

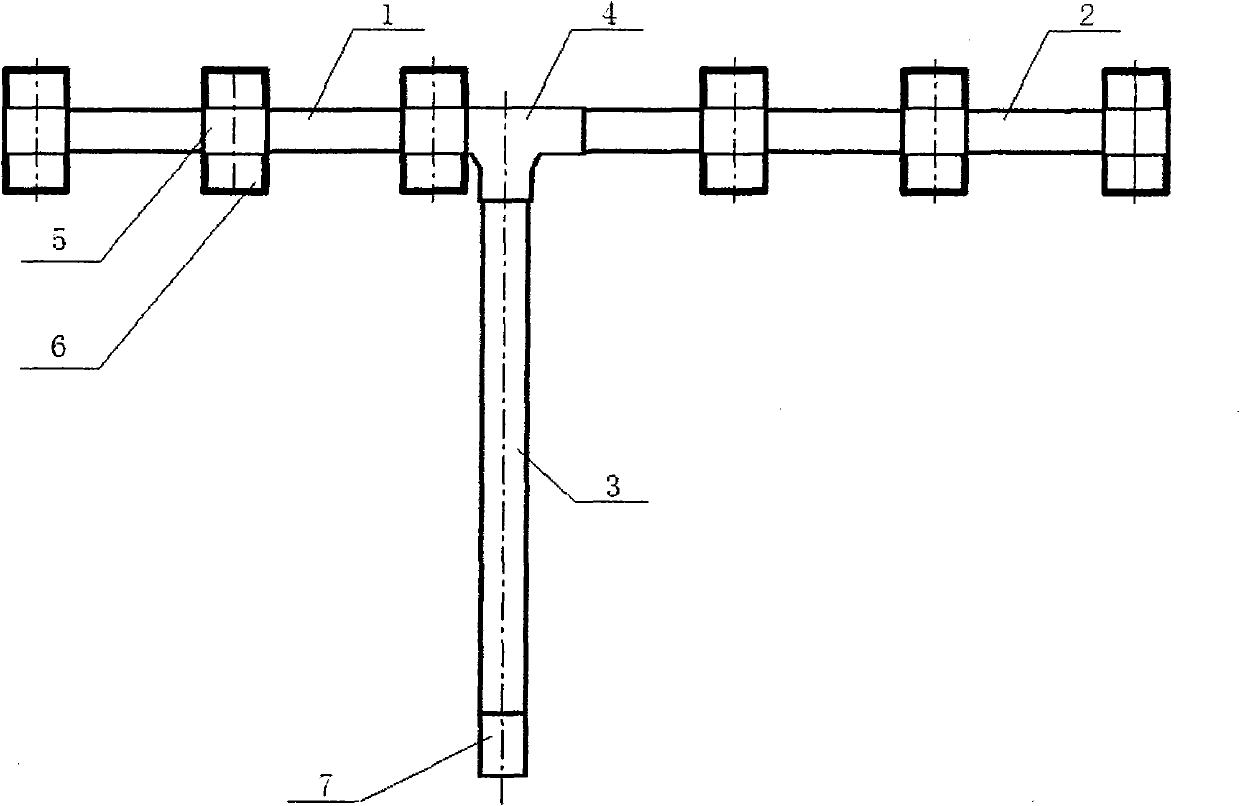

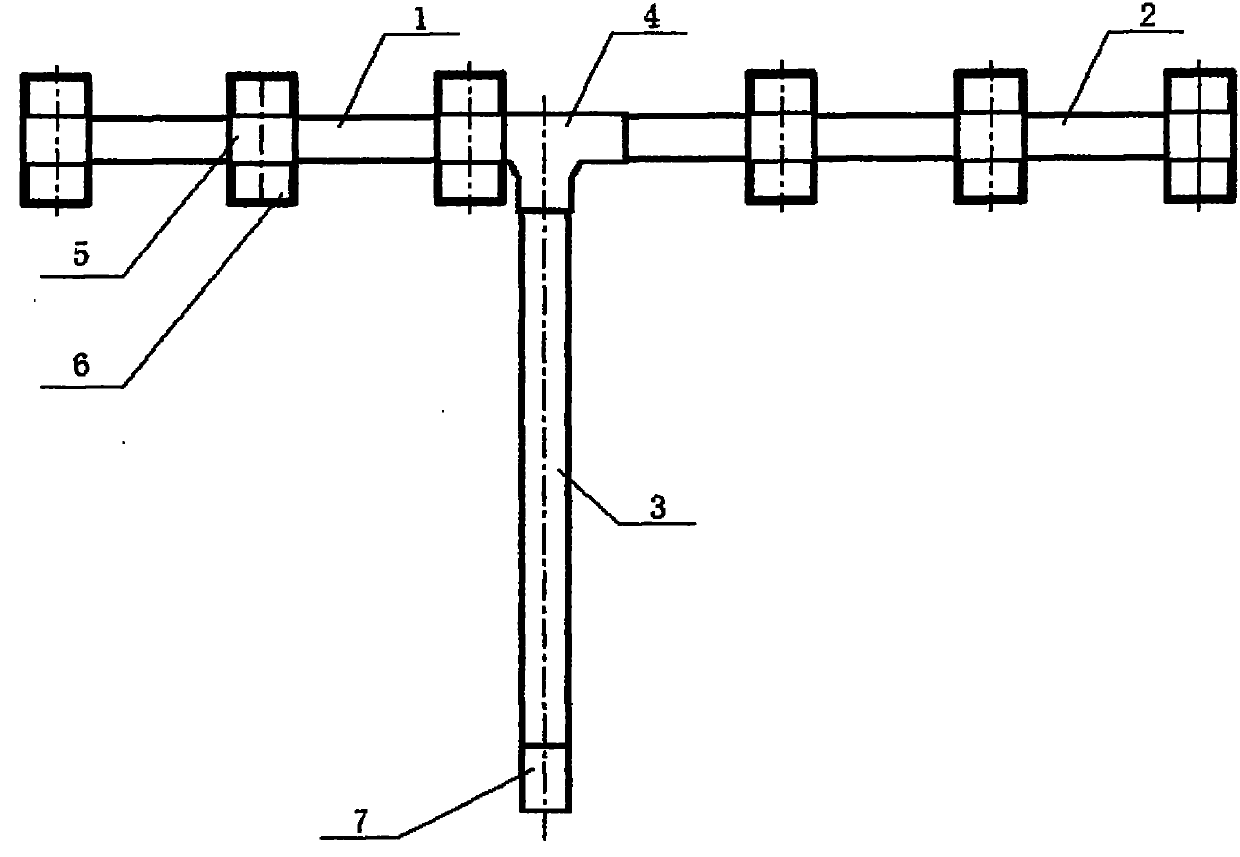

[0022] attached figure 1 It is a structural schematic diagram of a composite material mechanical arm of the present invention, and the structure of the mechanical arm is:

[0023] Three carbon fiber / epoxy composite rods (1, 2, 3) are glued on the carbon fiber / epoxy composite material T-shaped joint (4) to form the main frame T-shaped beam of the mechanical arm. Get six screw holes on the cross bar (1) and cross bar (2) of the beam and connect with six carbon fiber / epoxy composite material saddles (6) by rivets. The saddle (6) is connected with the carbon fiber / epoxy composite material mounting support (5) through adhesive bonding. In order for the composite manipulator to be installed on the transfer robot, it is necessary to install a metal connection joint (7) under the manipulator, and apply J-133 glue to the end of the vertical bar (3) of the T-beam to connect with the metal in the form of glue Connec...

Embodiment 2

[0024] Example 2: Preparation method of composite material manipulator

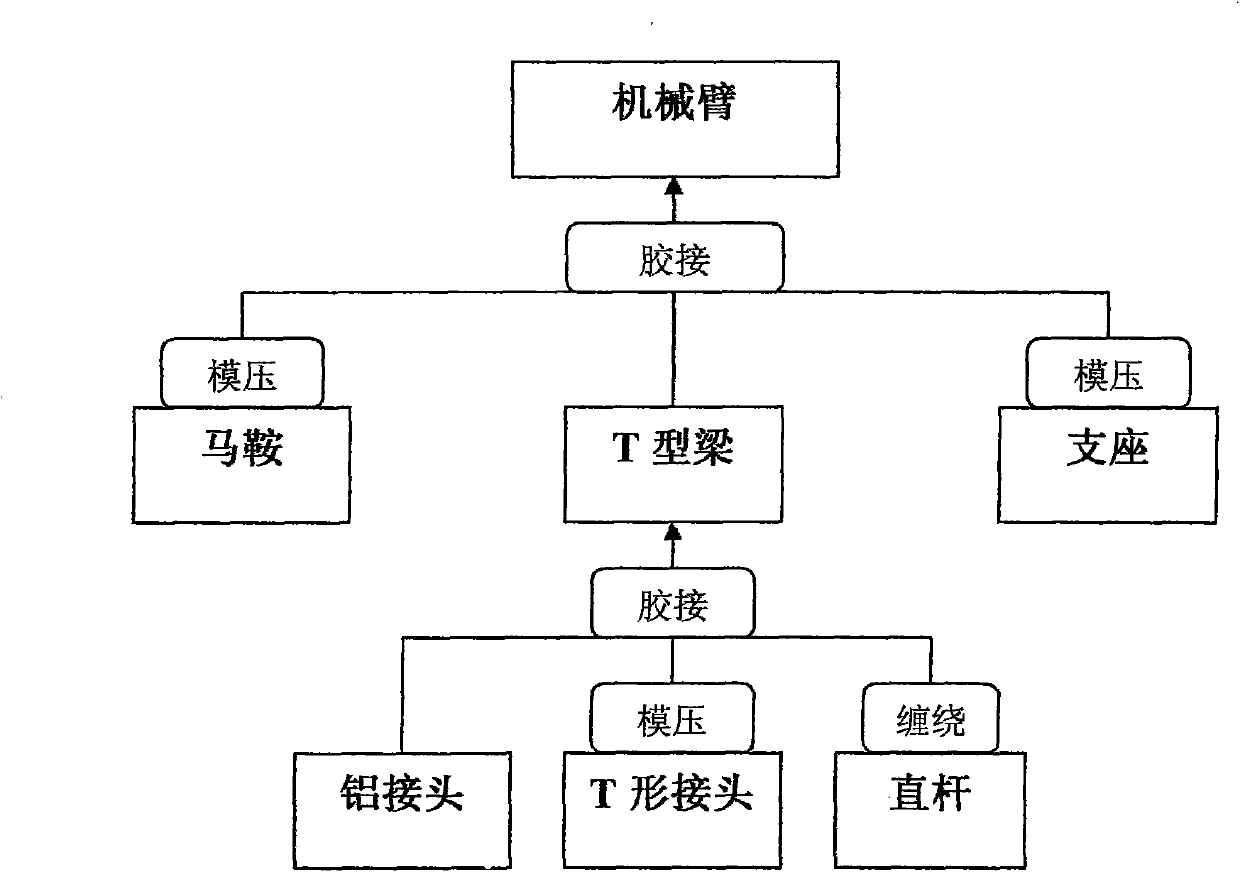

[0025] attached figure 2 It is a schematic diagram of the product structure composition of a composite material manipulator of the present invention. In conjunction with this accompanying drawing, the production process flow of the present invention is described.

[0026] According to the T-shaped joint structure, carbon fiber / epoxy prepreg is used to lay the layers, and the T-shaped joint is formed by composite material joint molding process. Then wind three straight rods at a winding angle of ±30°. Use J-133 glue to glue the three straight rods on the T-shaped joints, and glue the aluminum alloy connection joints to the vertical rods.

[0027] Lay the layers with carbon fiber / epoxy prepreg cloth, and mold the saddle and support by composite material joint molding process. The saddle and support are glued and connected with J-133 glue, and rivet holes are made on the crossbar of the T-beam. The sadd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com