Flavored milk containing ganoderma extract and preparation method thereof

A technology of Ganoderma lucidum extract and flavored milk, applied in dairy products, milk preparations, applications, etc., can solve the problems of protein precipitation, stability decline, protein denaturation, etc., reduce lipid peroxidation level, increase antioxidant Enzyme activity, effect of scavenging oxygen free radicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

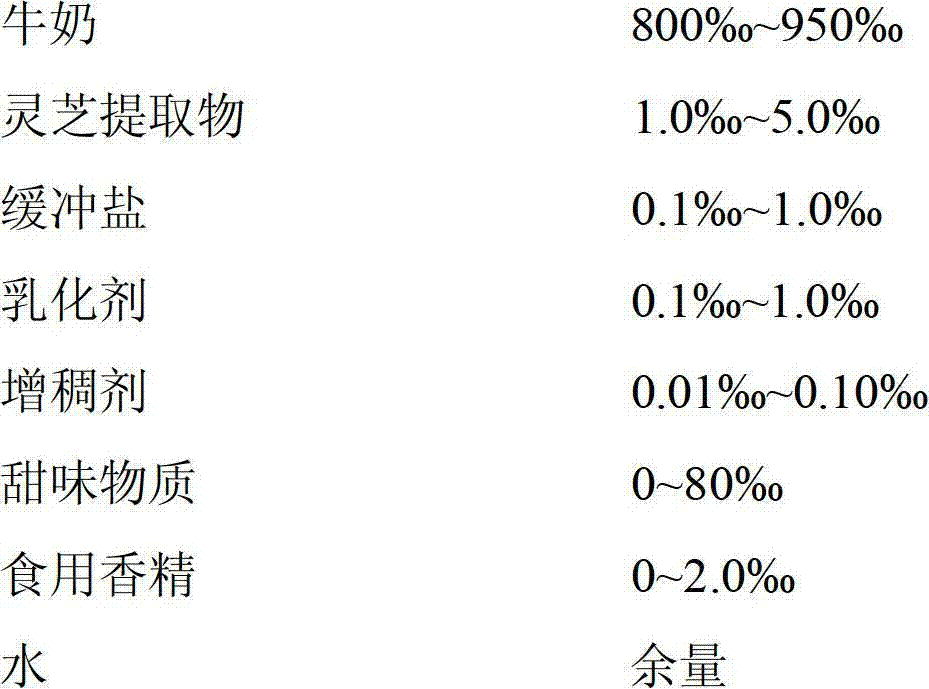

[0042] One, the raw material formula of the flavored milk containing the Ganoderma lucidum extract of the present embodiment is:

[0043] Whole milk 800‰

[0044] White sugar 50‰

[0045] Ganoderma lucidum extract 1.0‰

[0046] Glyceryl monostearate 0.6‰

[0047] Xanthan gum 0.03‰

[0048] Sodium hexametaphosphate 0.1‰

[0049] Powder food flavor 0.2‰

[0050] Purified water balance

[0051] The performance indicators of each raw material meet the requirements of relevant quality standards.

[0052] Two, the production method of the flavored milk of the present embodiment mainly comprises the following steps:

[0053] 1. Milk inspection: It is required that the fat, protein, dry matter and other indicators meet the quality standards of raw milk, and refrigerated below 4°C.

[0054] 2. Ingredients: Put 20% of the total amount of milk into the chemical material tank, heat it to 60°C, add the mixed glyceryl monostearate, xanthan gum, powdered spices and sugar, and use a h...

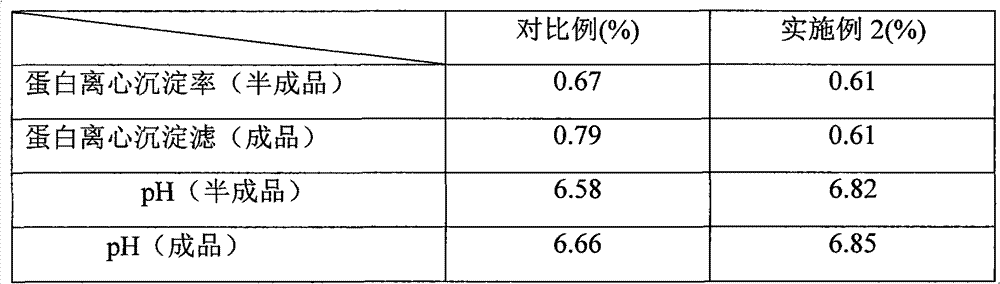

Embodiment 2

[0062] One, the raw material formula of the flavored milk containing the Ganoderma lucidum extract of the present embodiment is:

[0063] Whole milk 950‰

[0064] White sugar 70‰

[0065] Ganoderma lucidum extract 3.5‰

[0066] Sucrose fatty acid ester 0.3‰

[0067] Xanthan gum 0.03‰

[0068] Sodium alginate 0.05‰

[0069] Sodium bicarbonate 0.2‰

[0070] Powder food flavor 0.2‰

[0071] Purified water balance

[0072] The performance indicators of each raw material meet the requirements of relevant quality standards.

[0073] Two, the production method of the flavored milk of the present embodiment mainly comprises the following steps:

[0074] 1. Milk inspection: It is required that the fat, protein, dry matter and other indicators meet the quality standards of raw milk, and refrigerated below 4°C.

[0075] 2. Ingredients: Put 20% of the total amount of milk into the chemical material tank, heat it to 60°C, add the mixed sucrose fatty acid ester, xanthan gum, sodium...

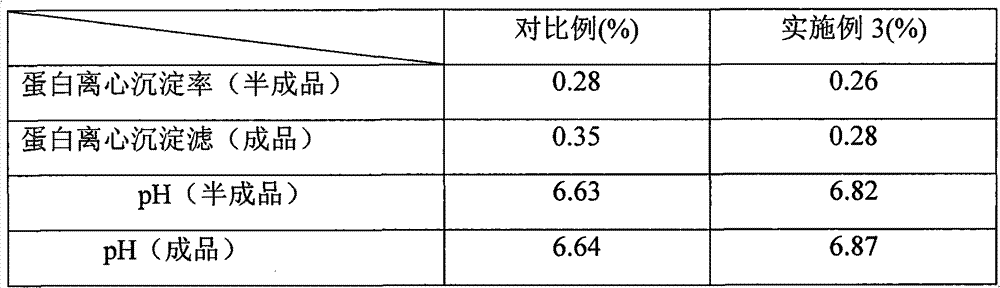

Embodiment 3

[0083] One, the raw material formula of the low-fat flavored milk containing Ganoderma lucidum extract of the present embodiment is:

[0084] Low-fat milk 850‰

[0085] Sucralose (Taylor, USA) 0.07‰

[0086] Ganoderma lucidum extract 5.0‰

[0087] Sodium stearoyl lactylate 0.7‰

[0088] Modified starch 0.05‰

[0089] Sodium bicarbonate 1.0‰

[0090] Food flavor 0.8‰

[0091] Purified water balance

[0092] The performance indicators of each raw material meet the requirements of relevant quality standards.

[0093] Two, the production method of the flavored milk of the present embodiment mainly comprises the following steps:

[0094] 1. Milk inspection: It is required that the fat, protein, dry matter and other indicators meet the quality standards of raw milk, and refrigerated below 4°C.

[0095] 2. Skim separation of milk: use separation to separate the fat of raw milk to 1.4-1.5%

[0096] 3. Ingredients: Pour 20% low-fat milk into the chemical tank, heat to 60°C, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com