Nitride semiconductor light emitting element and method for manufacturing same

一种氮化物类、发光元件的技术,应用在半导体/固态器件制造、半导体器件、电气元件等方向,达到抑制非均匀应变分布的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

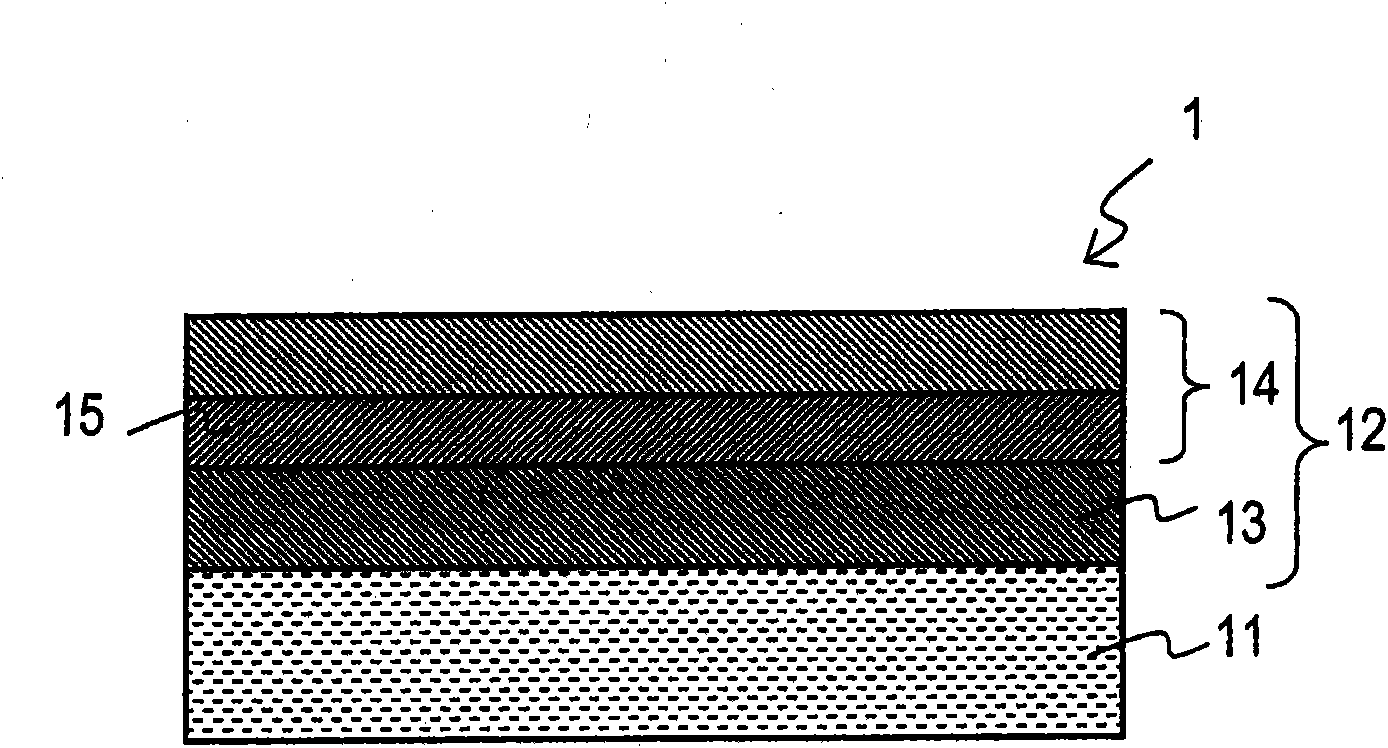

[0089] First, refer to figure 1 A first embodiment of the nitride-based semiconductor light-emitting device according to the present invention will be described.

[0090] The nitride-based semiconductor light-emitting element 1 of the present embodiment is, for example, figure 1 Shown are: a selective growth layer 11 , and a nitride-based semiconductor stack structure 12 formed on the selective growth layer 11 . The selective growth layer 11 has a portion grown laterally by the ELO method.

[0091]The nitride-based semiconductor stack structure 12 includes: an active layer 13 including Al a In b Ga c N crystal layer (a+b+c=1, a≥0, b≥0, c≥0); Al d Ga e The N layer (d+e=1, d>0, e≥) 14 is located on the side opposite to the side where the selective growth layer 11 is located relative to the active layer 13 .

[0092] Al d Ga e Part of the N layer 14 has a layer (In-containing layer) 15 containing In at a concentration of 1×10 16 atms / cm 3 Above 1×10 19 atms / cm 3 The ...

Embodiment approach 2

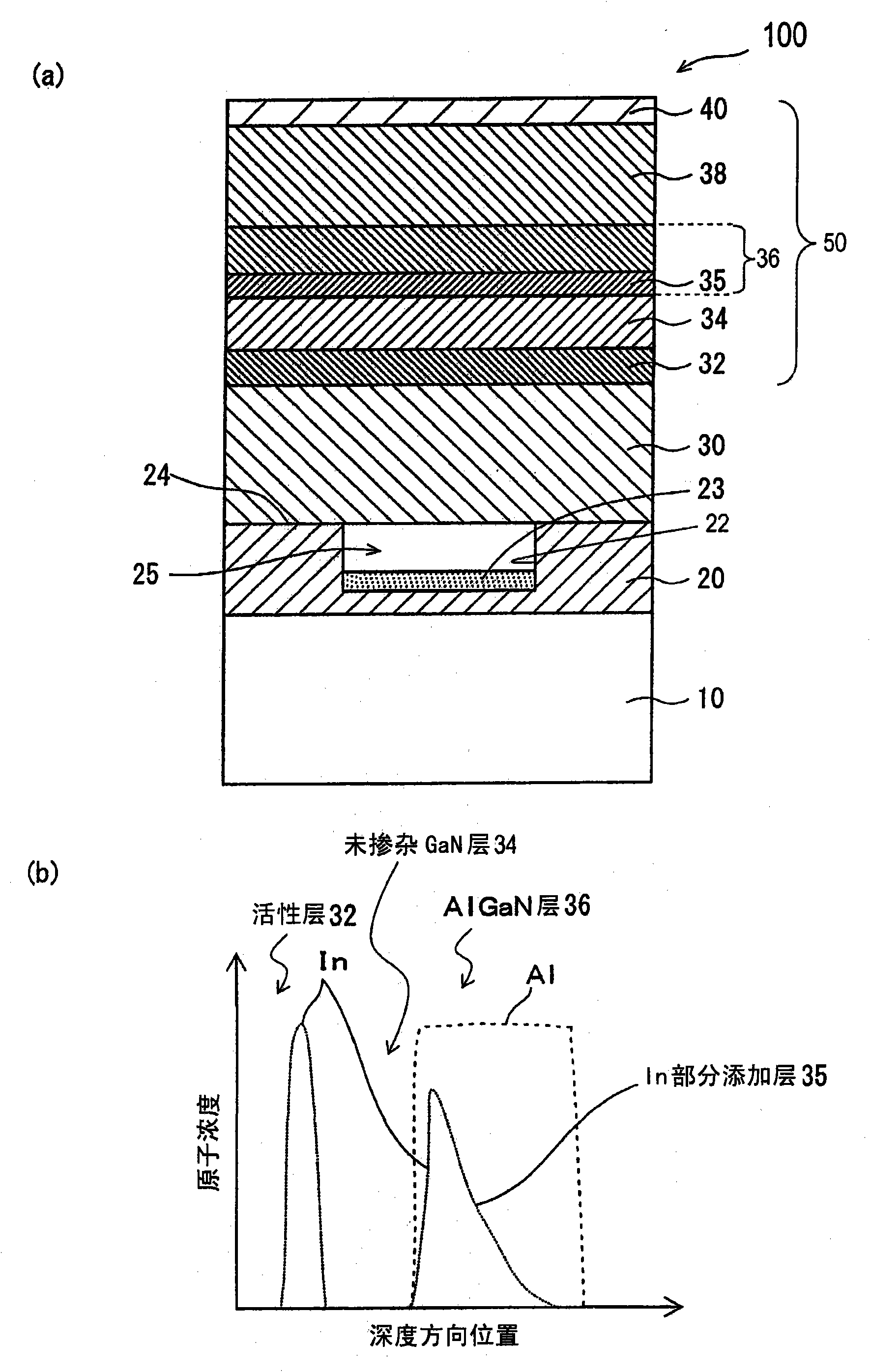

[0098] Below, refer to Figure 2 to Figure 20 A second embodiment of the nitride-based semiconductor light-emitting element according to the present invention will be described. The nitride-based semiconductor light-emitting element 100 of this embodiment is a semiconductor device using a GaN-based semiconductor, and is produced by the ELO method in order to reduce rearrangement density.

[0099] Such as figure 2 As shown in (a), the light-emitting element 100 of this embodiment has: a substrate 10; u Ga v In w N layer (u+v+w=1, u≥0, v≥0, w≥0) 20, which is formed on the substrate 10; Al x Ga y In z N crystalline layer (x+y+z=1, x≥0, y≥0, z≥0) 30, which is formed on Al u Ga v In w N layer 20 functions as a selective growth layer; semiconductor stacked structure 50, which is formed on Al x Ga y In z N crystal layer 30.

[0100] in Al u Ga v In w The N layer 20 forms a groove (recess) 22 , and a mask 23 for selective growth is formed on the bottom surface of the ...

Embodiment approach 3

[0164] Below, refer to Figure 21 A third embodiment of the nitride-based semiconductor light-emitting diode according to the present invention will be described.

[0165] The nitride-based semiconductor light-emitting element 200 of this embodiment is, for example, Figure 21 Shown are a GaN substrate 60 and a semiconductor stack 70 formed on the GaN substrate 60 .

[0166] The GaN substrate 60 of this embodiment is formed by performing the ELO method. To obtain the GaN substrate 60 , for example, a GaN layer for the GaN substrate may be formed thick while covering a part of a sapphire substrate (not shown) with a mask made of a silicon oxide film and exposing the other part. In this method, the sapphire substrate is removed after the GaN layer is formed. Alternatively, mesh-shaped titanium may be formed on a GaN layer formed on a sapphire substrate, and a GaN layer for the GaN substrate may be formed thereon. In this method, after the GaN layer is formed, titanium is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com