Materials measuring and proportioning control method in mechanical stirring type fuel oil watering device

A technology of mechanical stirring and ratio control, applied in the combustion method, liquid fuel supply/distribution, etc., can solve the problems of difficult preparation and poor operability, and achieve significant fuel saving effect, reduction of exhaust gas temperature, and reduction of output heat. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

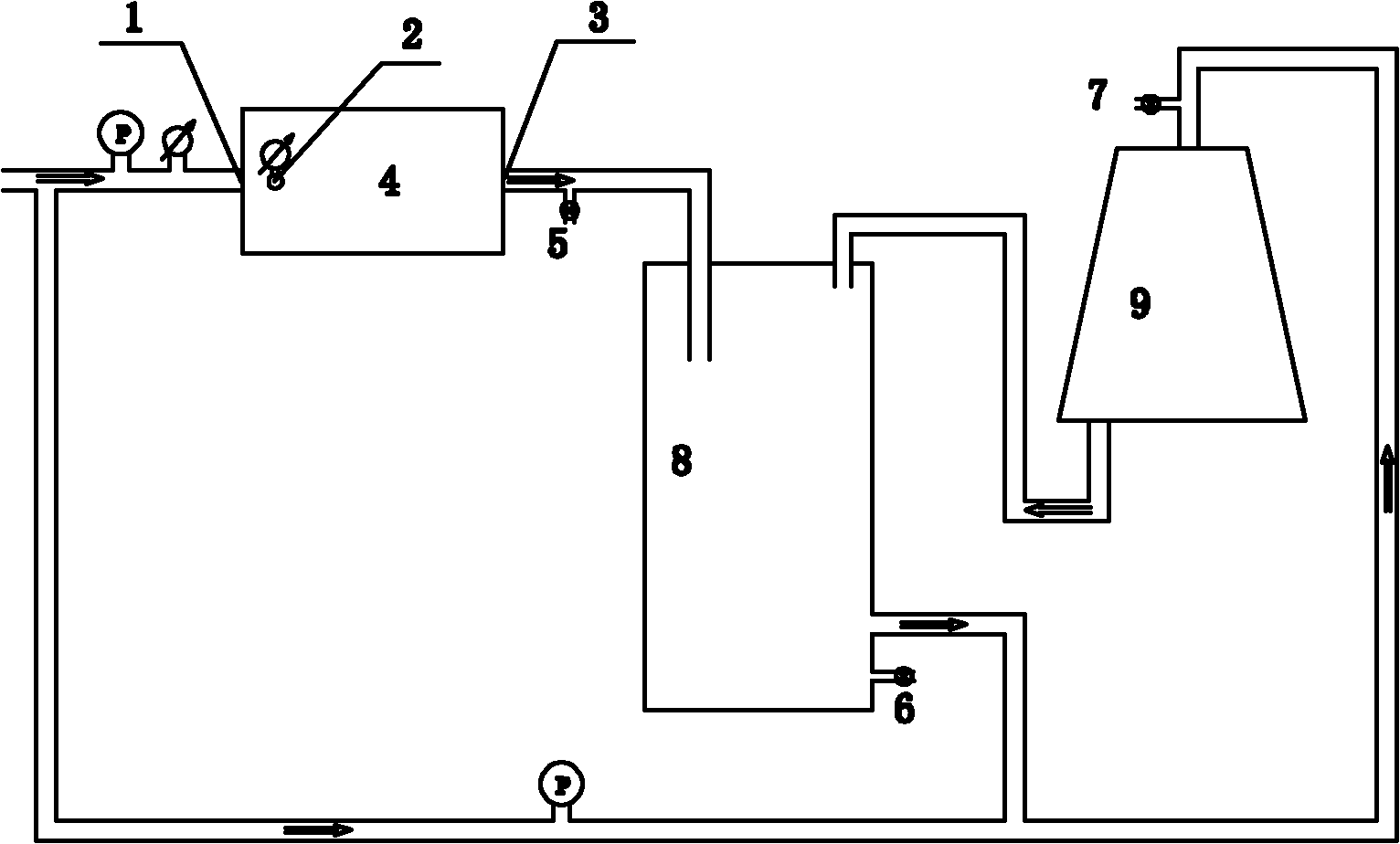

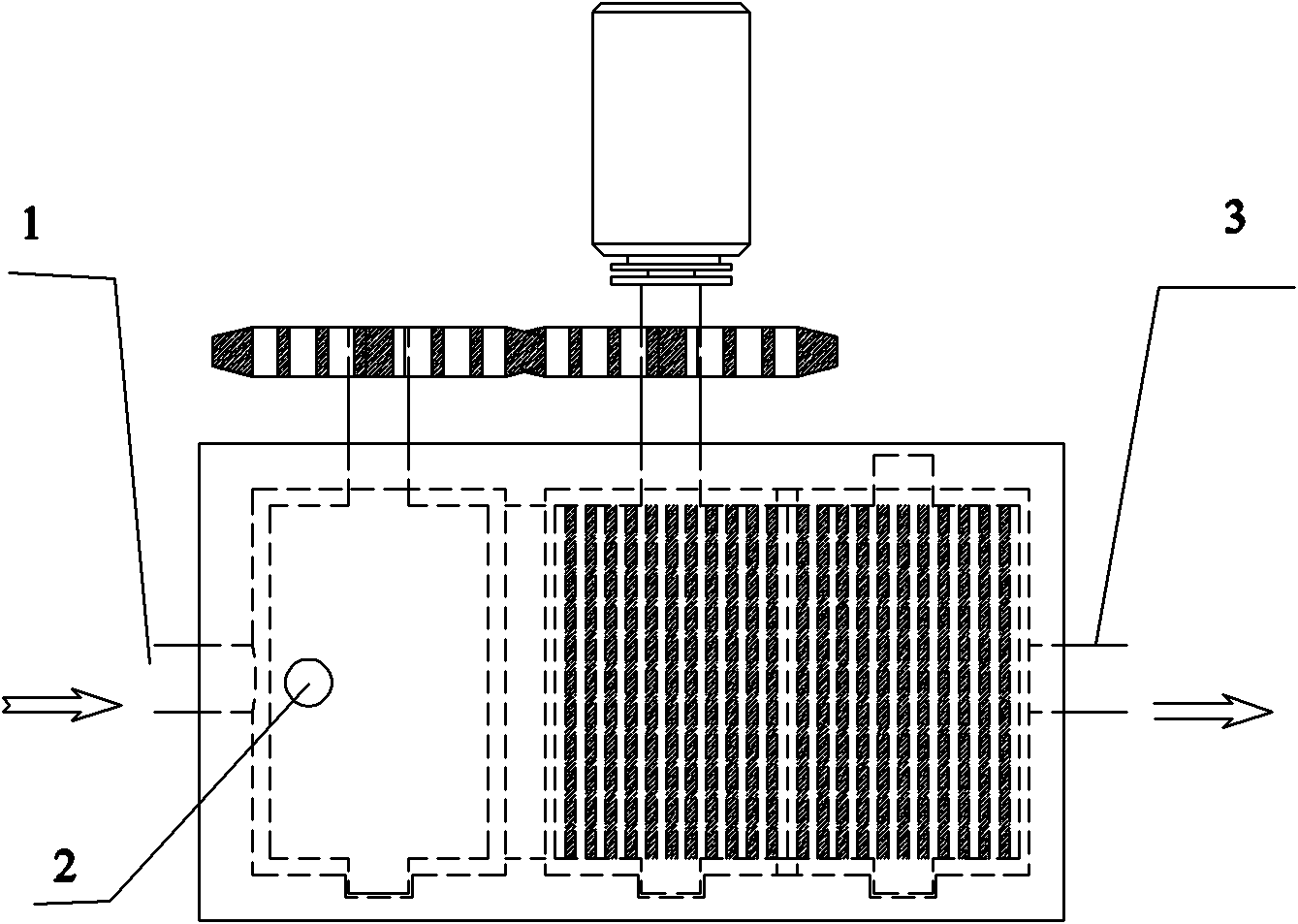

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the examples.

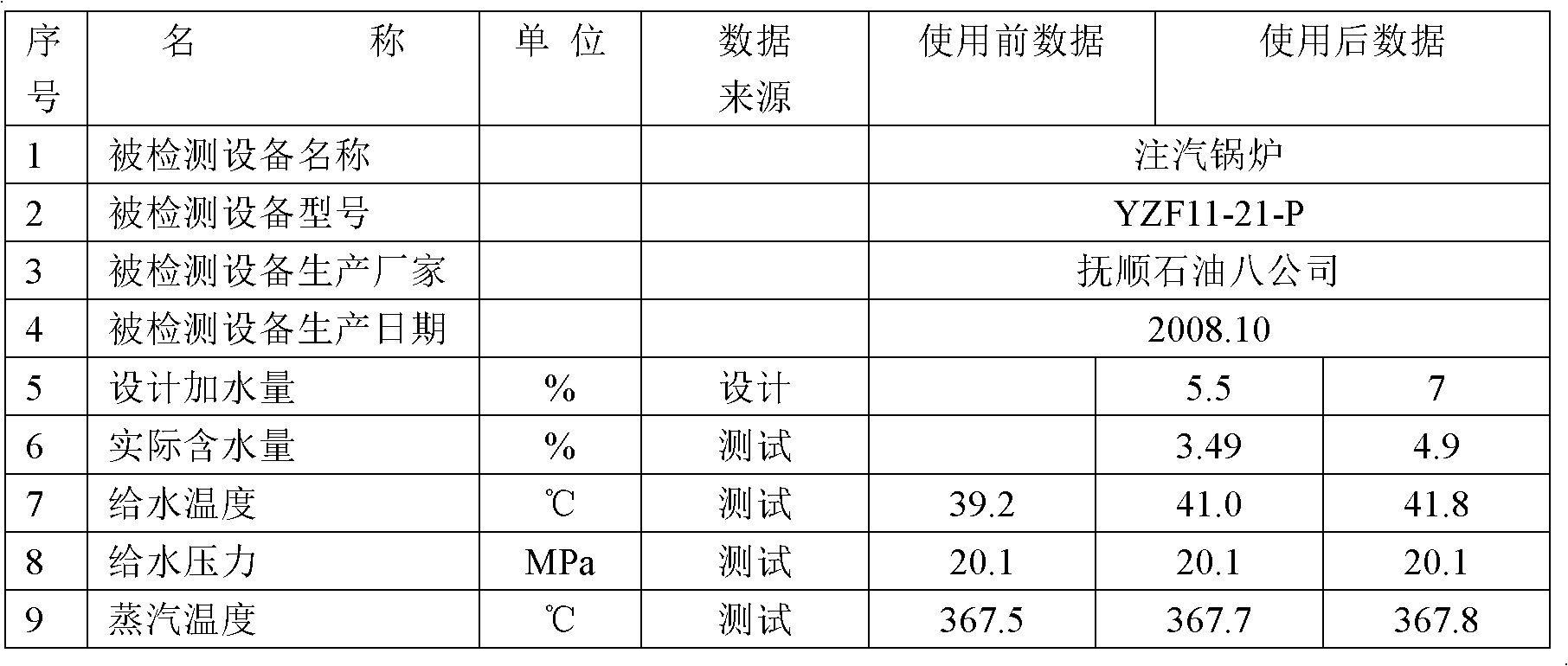

[0015] Apply this water mixing control scheme to the steam injection boiler, and use the combination of positive and negative balance method tests to conduct tests. The efficiency measured by the positive balance method test is the main one; ) to measure CO after combustion x and dust concentration, the stirring rate is 1200r / min, and the continuous stirring operation is implemented; the operating load fluctuation range of the furnace is within ±10% during the test; the test is carried out when the thermal working condition of the furnace is stable, and the stabilization time is from the cold state ignition to the formal test. Less than 8 hours, the combustion quality of the boiler is basically the same when it is running. The test results are shown in the table below.

[0016]

[0017]

[0018] Under the test conditions at that time, CO 2 content is 8.6%, CO content is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com