Mineral deep hole drilling carriage unit

The technology of a deep hole drilling rig and unit is applied in the fields of drilling equipment and mining deep hole drilling rigs, which can solve the problems of small adjustable drilling angle, high overall height of the machine body, and large space occupation, so as to reduce physical strength. The effect of labor intensity, good mobility and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

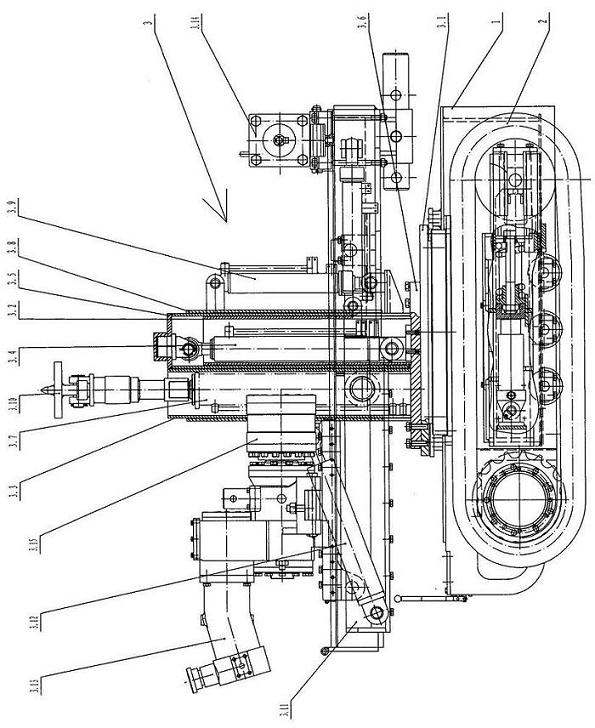

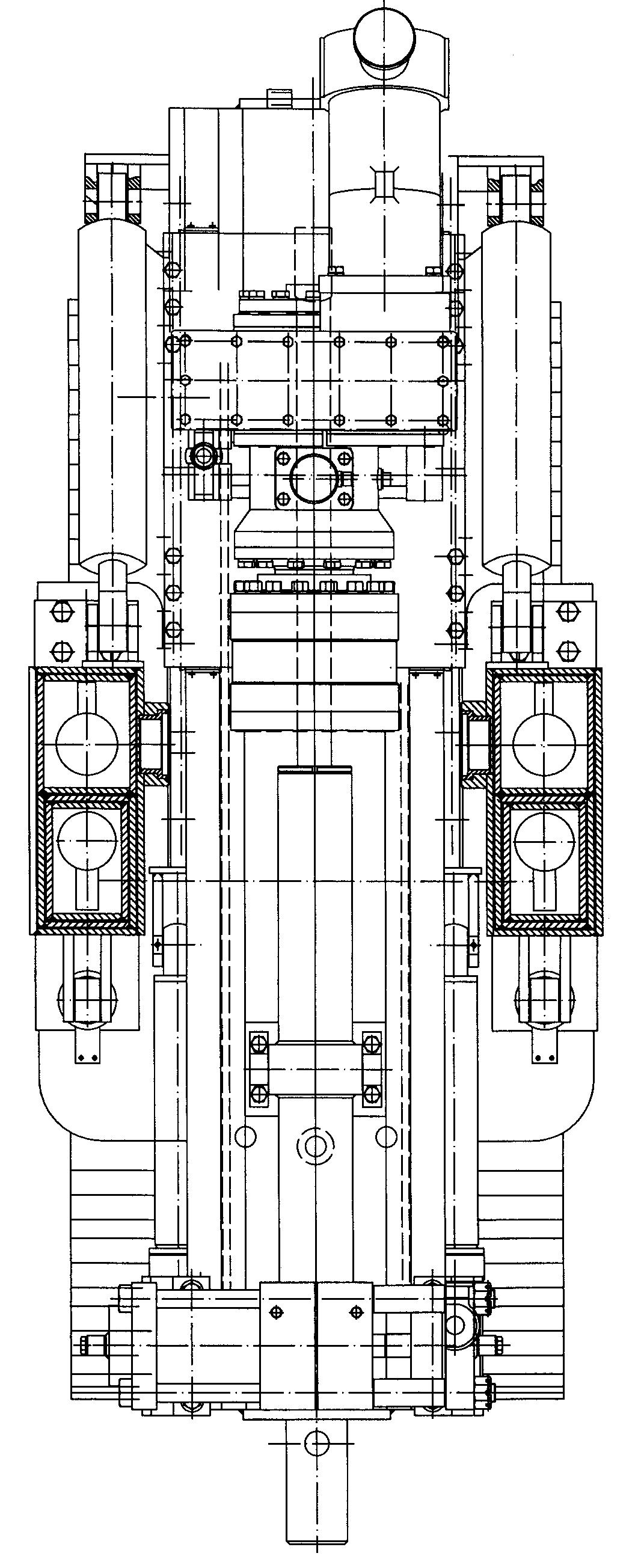

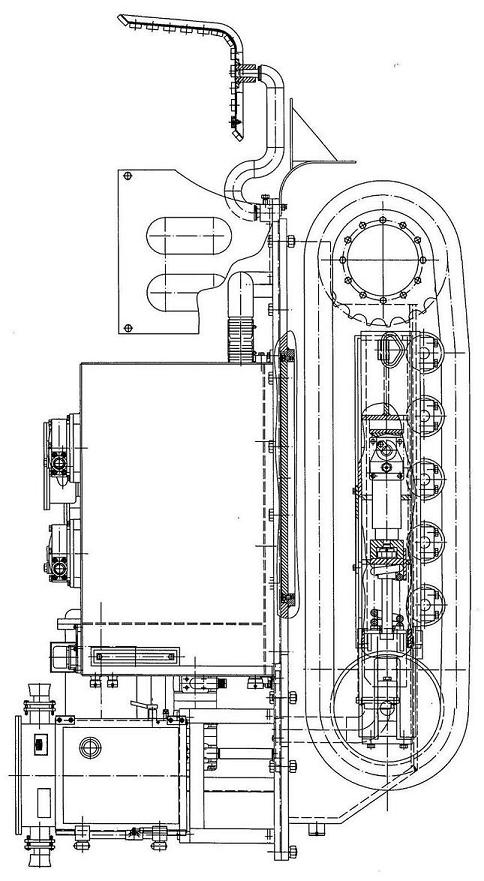

[0023] see Figure 1-Figure 4 , a deep hole drilling rig unit for mines that the present invention relates to mainly consists of two parts: a main engine and a pumping station;

[0024] see Figure 1-2 The main engine is mainly composed of a frame 1, a crawler walking device 2 arranged on both sides of the frame 1, and a working mechanism 3 installed on the frame 1;

[0025] The working mechanism 3 includes a rotating chassis 3.1, a column 3.2, an upper support column 3.3, a first cylinder 3.4, a middle cover 3.5, a fixed plate 3.6, an upper support cylinder 3.7, an outer cover 3.8, a second cylinder 3.9, a top seat 3.10, a slide Assembly 3.11, compensation cylinder 3.12, swivel mechanism 3.13, holder 3.14 and chuck 3.15.

[0026] The rotating chassis 3.1 is connected to the frame 1 through a slewing bearing, and the rotating chassis 3.1 is provided with two fixed plates 3.6 symmetrically on the left and right, and the two fixed plates 3.6 are respectively fixed side by side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com