Pipelined clothes atomization post-treatment device applicable to nano after-finishing

A post-processing device and assembly-line technology, which is applied in spray/jet textile material processing, textile material processing, textile and papermaking, etc., can solve the problems of clothing nano-finishing efficiency limitation and difficult to achieve excellent finishing effect, etc. Achieve excellent durability, reduce post-processing costs, simple and fast process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

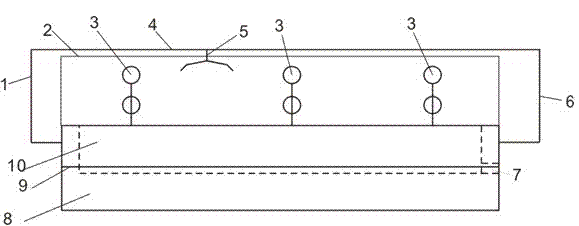

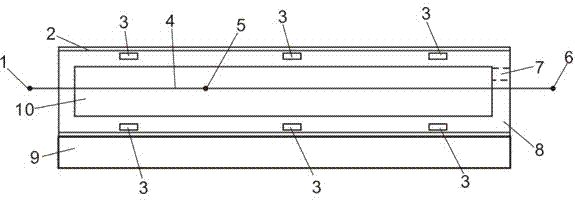

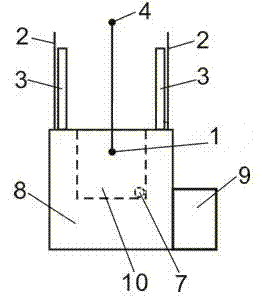

[0015] Such as figure 1 , 2 , shown in 3, a kind of assembly line type clothes after-treatment device of spraying, comprises flow operation workbench, clothes hanger transmission device, flow operation workbench comprises main workbench 8, and main workbench 8 side is provided with standing platform 9, for workers Can stand at a higher place, conveniently move the sliding hook of the clothes hanger; the upper surface of the main workbench 8 is provided with an inner depression to form a waste liquid tank 10, and one end of the waste liquid tank 10 is provided with a diversion hole 7, and the diversion hole 7 passes through the main working table The end face of platform 8; three spray groups 3 are evenly arranged on the main workbench 8 on both sides of waste liquid tank 10, and each spray group 3 is composed of 2 high-pressure nozzles arranged vertically, and the lower end of spray group 3 is connected with The other end of the pipeline is connected to the processing hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com