Process and complete equipment for pretreating coal tar

A complete set of equipment and pretreatment technology, applied in tar processing, tar removal processing through water, petroleum industry, etc., to achieve the effects of reducing energy consumption, reducing the impact of catalysts, and high economic benefits

Inactive Publication Date: 2011-06-01

江苏三星化工有限公司

View PDF8 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to make the coal tar pretreatment adapt to the large

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

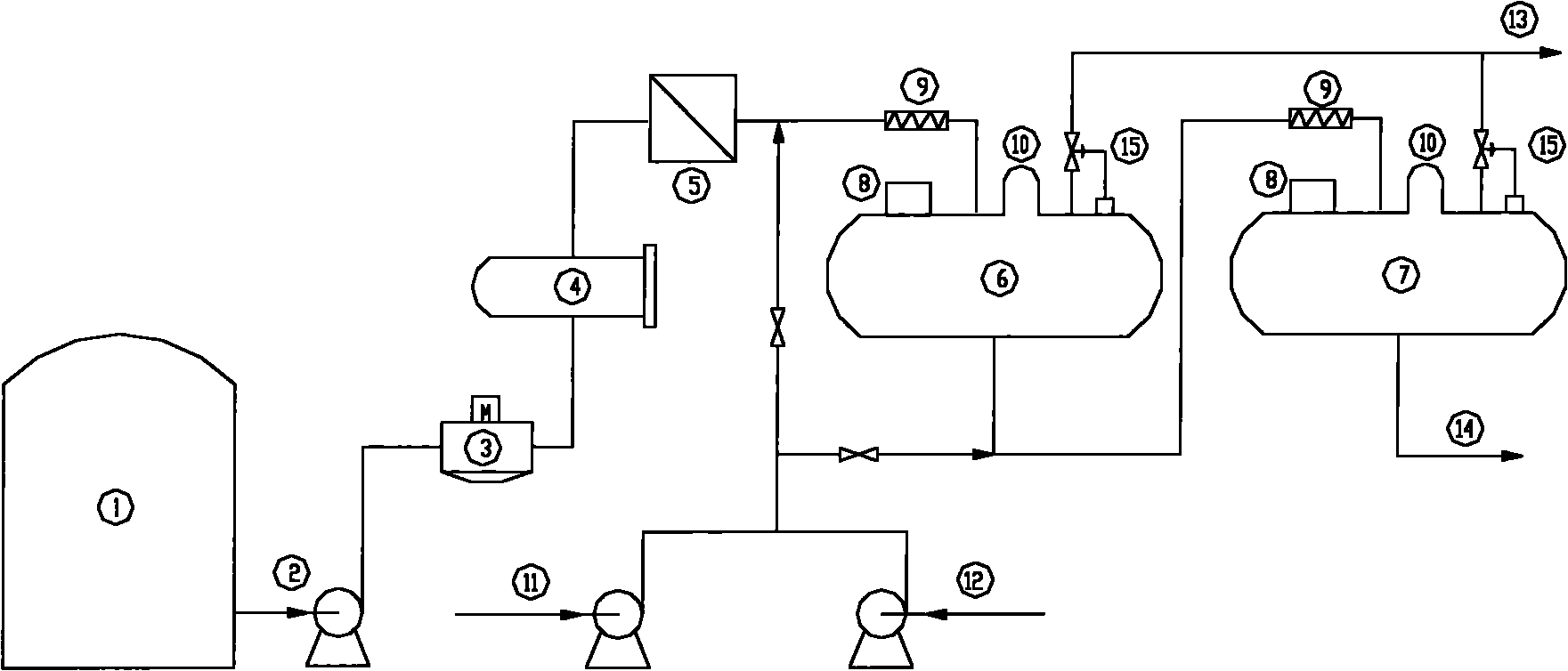

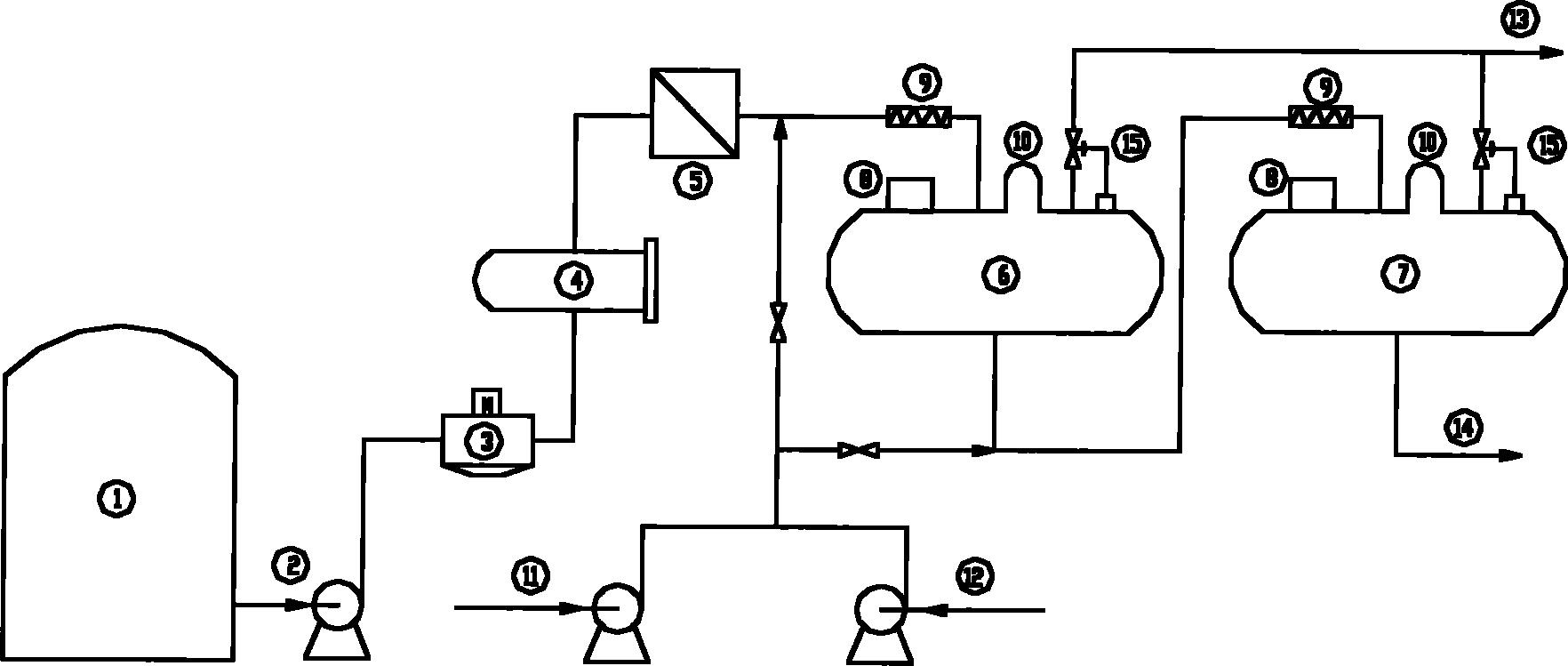

The invention discloses a process and complete equipment for pretreating coal tar. The complete equipment are an integrated pretreatment system jointly formed by a coal tar raw material storage tank (1), a three-phase centrifugal machine (3), an automatic back wash filter (5), a primary high-voltage electric field knockout drum (6), a secondary high-voltage electric field knockout drum (7) and the like. The process and complete equipment provided by the invention are suitable for the process requirements for large-scale deep pretreatment desalination, dehydration and impurity removal in a modern coal tar deep processing industry. The processing effects of the two-stage electric field knockout drums are greatly improved by using a high-voltage impulse power supply.

Description

technical field [0001] The invention relates to the field of deep processing and utilization of coal tar resources, and provides a process method and a complete set of equipment for large-scale centralized pretreatment of coal tar, so that the treated coal tar can meet the requirements of subsequent deep processing technology. Background technique [0002] Coal tar is one of the important products of the coking industry, and its composition is extremely complex. It is estimated that there are more than 10,000 kinds of organic compounds in coal tar, and about 500 kinds have been identified, which is a very complex mixture. [0003] From 2004 to 2007, the average annual growth rate of China's coal tar production was 17.5%. In 2007, China's tar consumption was 8.6 million tons, of which 5.2 million tons were used for deep processing, accounting for 60.5% of the total tar consumption. By 2010, China's coal tar output is expected to be about 10.7 million tons. With the develop...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10C1/00C10C1/02

Inventor 刘建春王龙祥

Owner 江苏三星化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com