Encapsulating device

A potting and filling technology, applied in packaging, transportation and packaging, vacuum/special atmosphere packaging, etc., can solve the problem of increasing the difficulty and intensity of the operator's work, the complex structure of the auger bottle output assembly, and the lack of bottle handover Stability and other issues, to achieve the effect of reducing work difficulty and labor intensity, good practicability, stable and safe transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

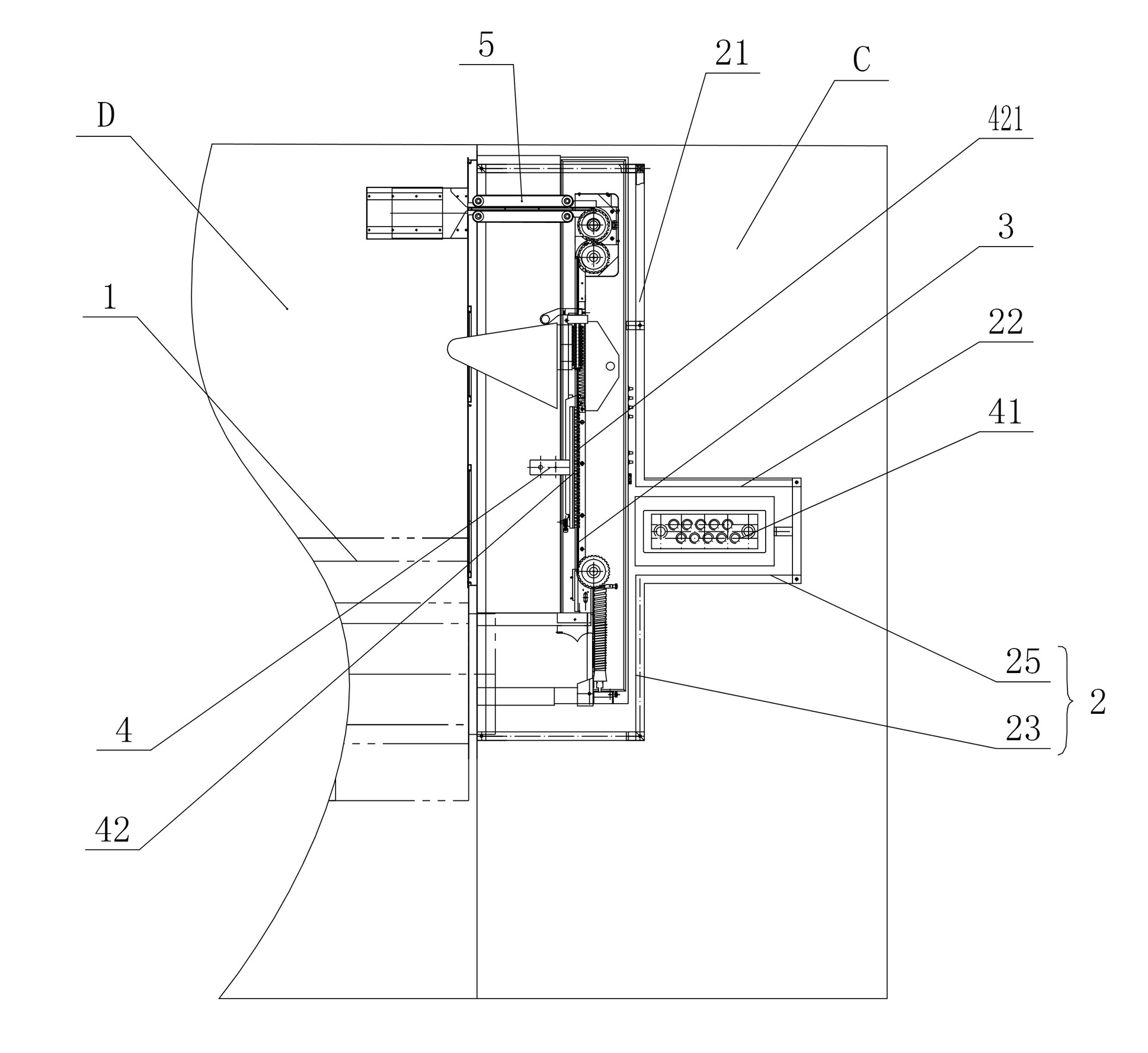

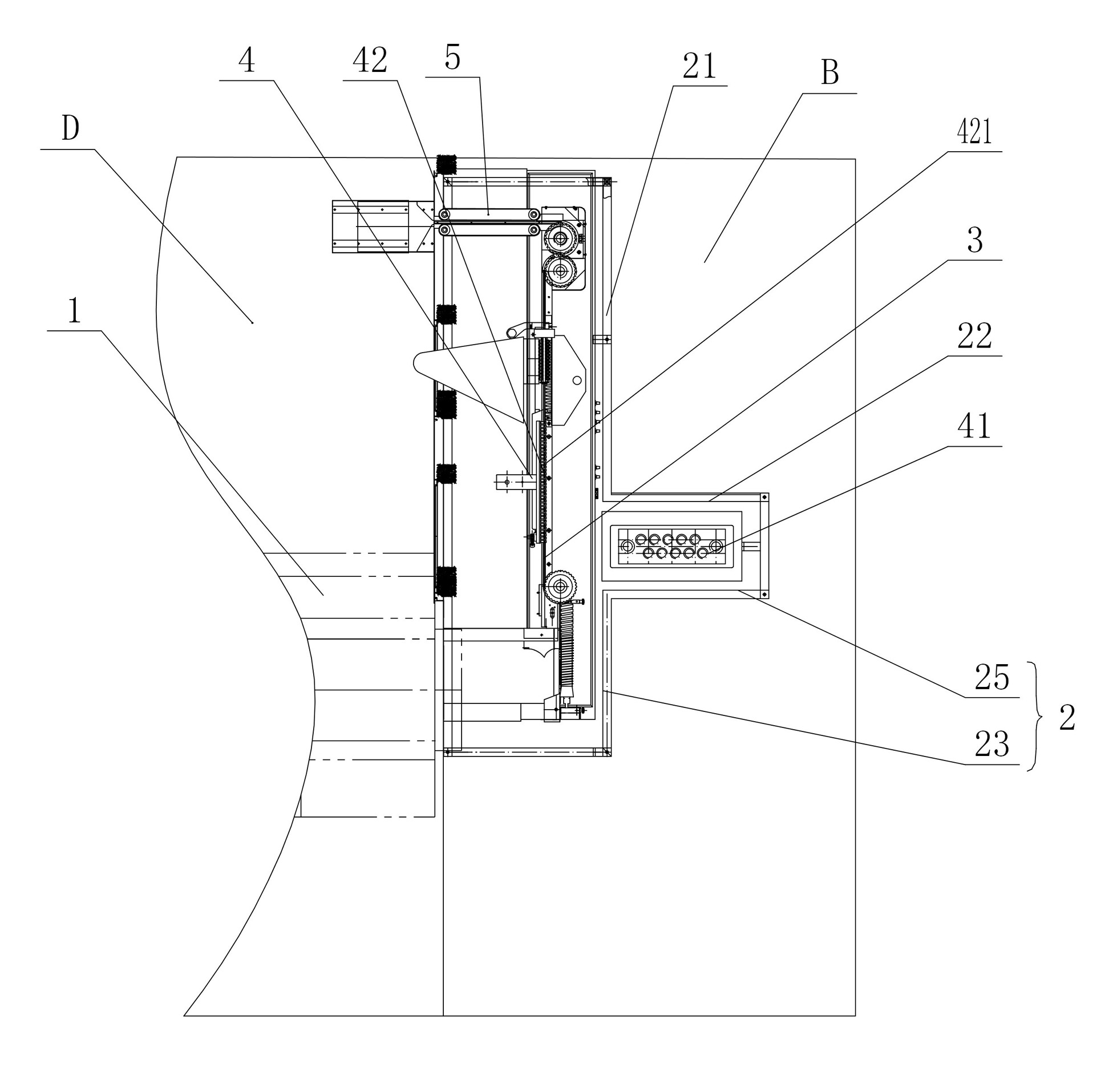

[0020] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

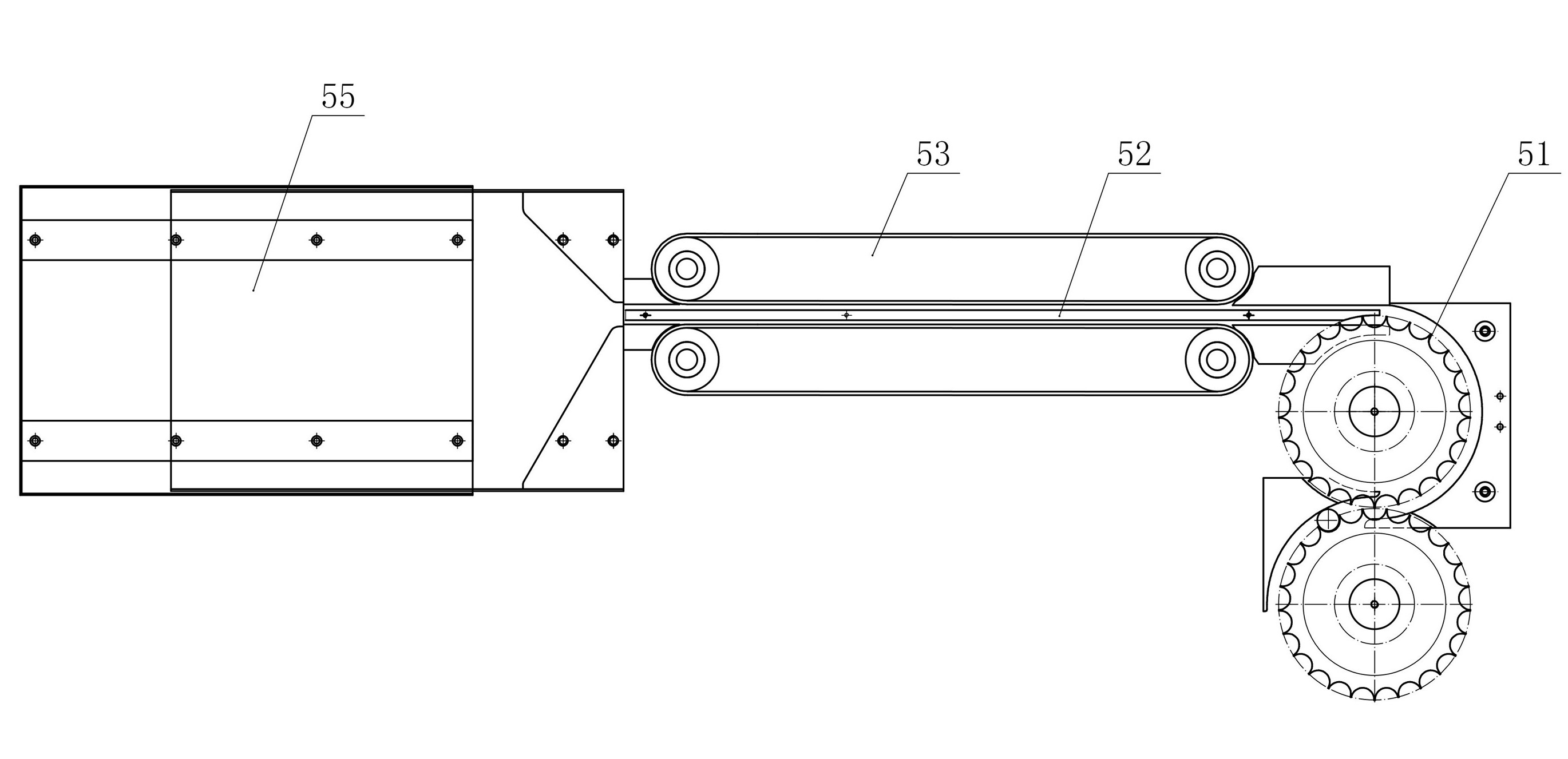

[0021] Such as figure 1 , figure 2 and image 3 As shown, the potting and sealing device of the present invention is embedded in the cleaning and drying device 1, and it includes an isolation cover 2, a filling machine, a sealing machine and a bottle output mechanism that are arranged in the isolation cover 2 and connected in sequence. The bottle mechanism includes a dial wheel bottle delivery assembly 51 and a bottle filling tray 55. The thumb wheel bottle delivery assembly 51 is located at the bottle outlet end of the sealing machine, between the bottle outlet end of the dial wheel bottle delivery assembly 51 and the bottle inlet end of the bottle filling tray 55. Connected by a friction belt assembly. A friction conveyor belt assembly is set between the dial wheel bottle conveying assembly and the bottling tray, and the bottle body can be sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com