Oven controlled crystal oscillator (OCXO) with acceleration compensation

A technology of constant temperature crystal oscillation and acceleration sensor, which is applied in power oscillators, electrical components, etc., can solve problems such as unstable performance of analog circuits, and achieve the effect of overcoming the influence of environmental temperature and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

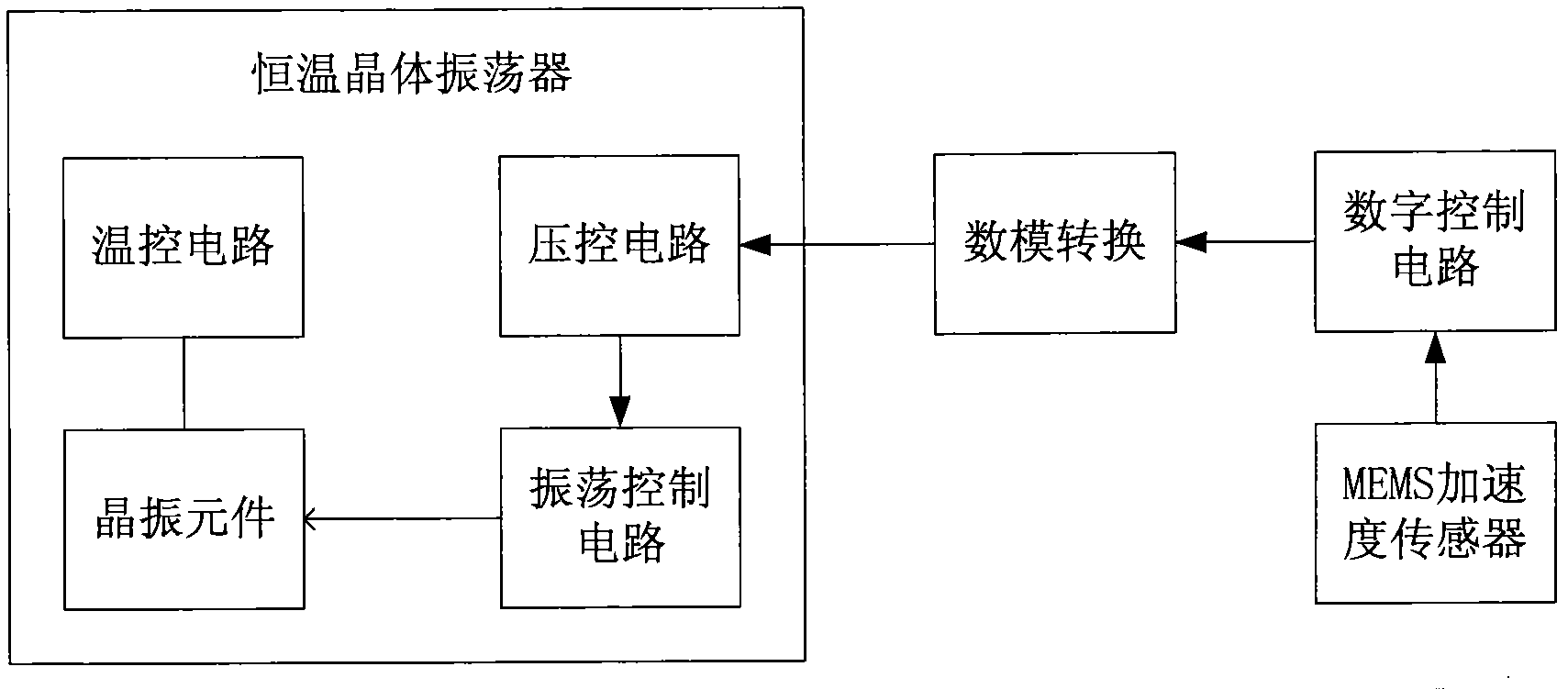

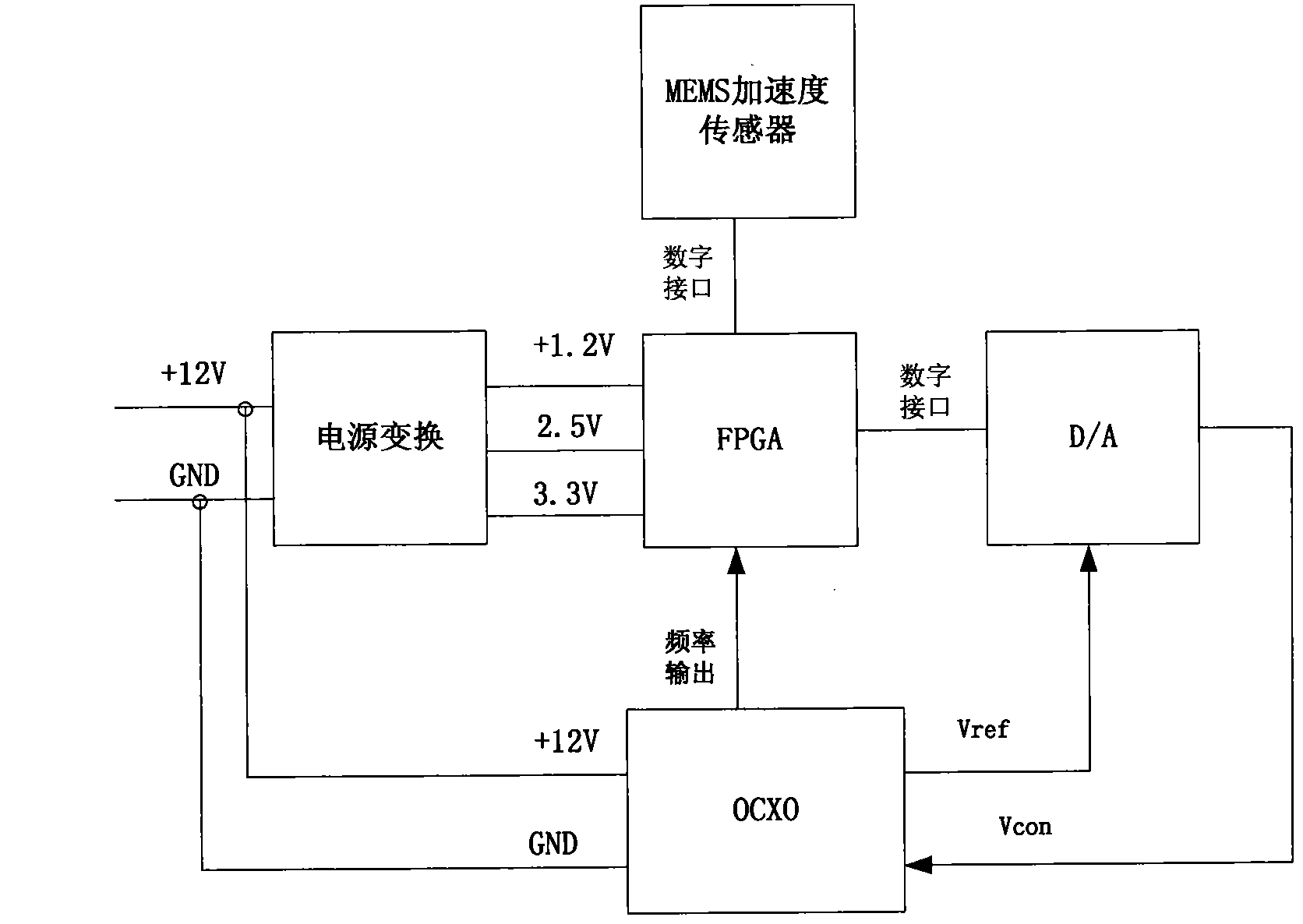

[0015] The constant temperature crystal oscillator (OCXO for short) generally has a temperature control circuit to precisely control the temperature of the crystal. The OCXO also has a voltage control circuit, and the output frequency can be adjusted by changing the voltage of the voltage control terminal. The present invention adds an acceleration compensation part inside the OCXO, which mainly includes a three-dimensional MEMS acceleration sensor, a digital control circuit based on FPGA, and a digital-to-analog conversion circuit (D / A for short). An OCXO with acceleration compensation consists of figure 1 shown.

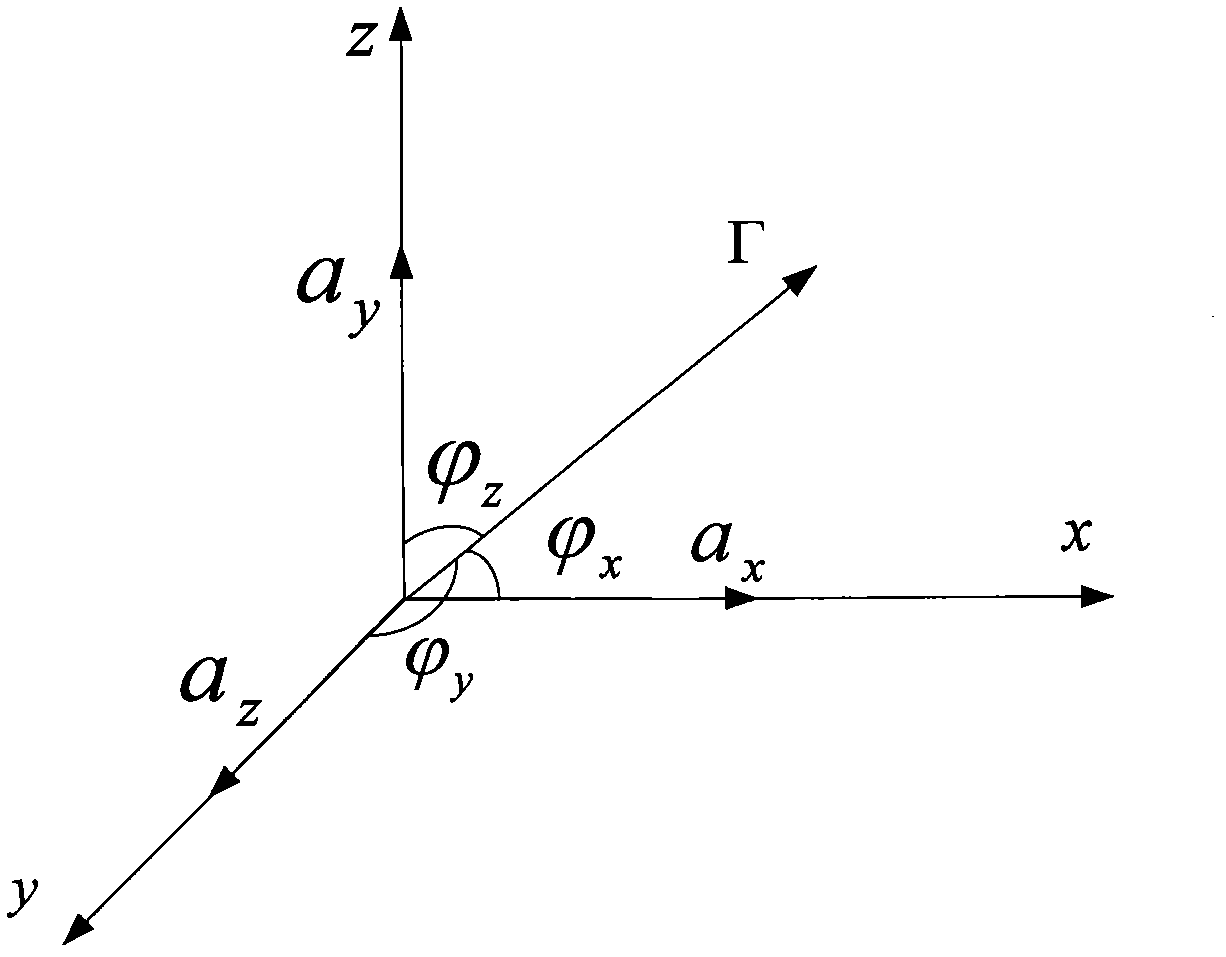

[0016] OCXOs have an inherent acceleration-sensitive direction that is determined and available through test methods. Let the angle between this direction and the x, y, z axes be mistake! Reference source not found. . Suppose the three-dimensional MEMS acceleration sensor detects the acceleration in three directions in real time, and the three-axis accelerati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com