Hot air circulation and exchange enameled oven

A technology of hot air circulation and enameling, applied in electrical components, circuits, insulation of conductors/cables, etc., can solve problems such as hindering the development and progress of enterprises, damage to human health, and a small number of catalytic zones, and is conducive to energy conservation and environmental protection. , Reduce working time and ensure the effect of furnace temperature requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

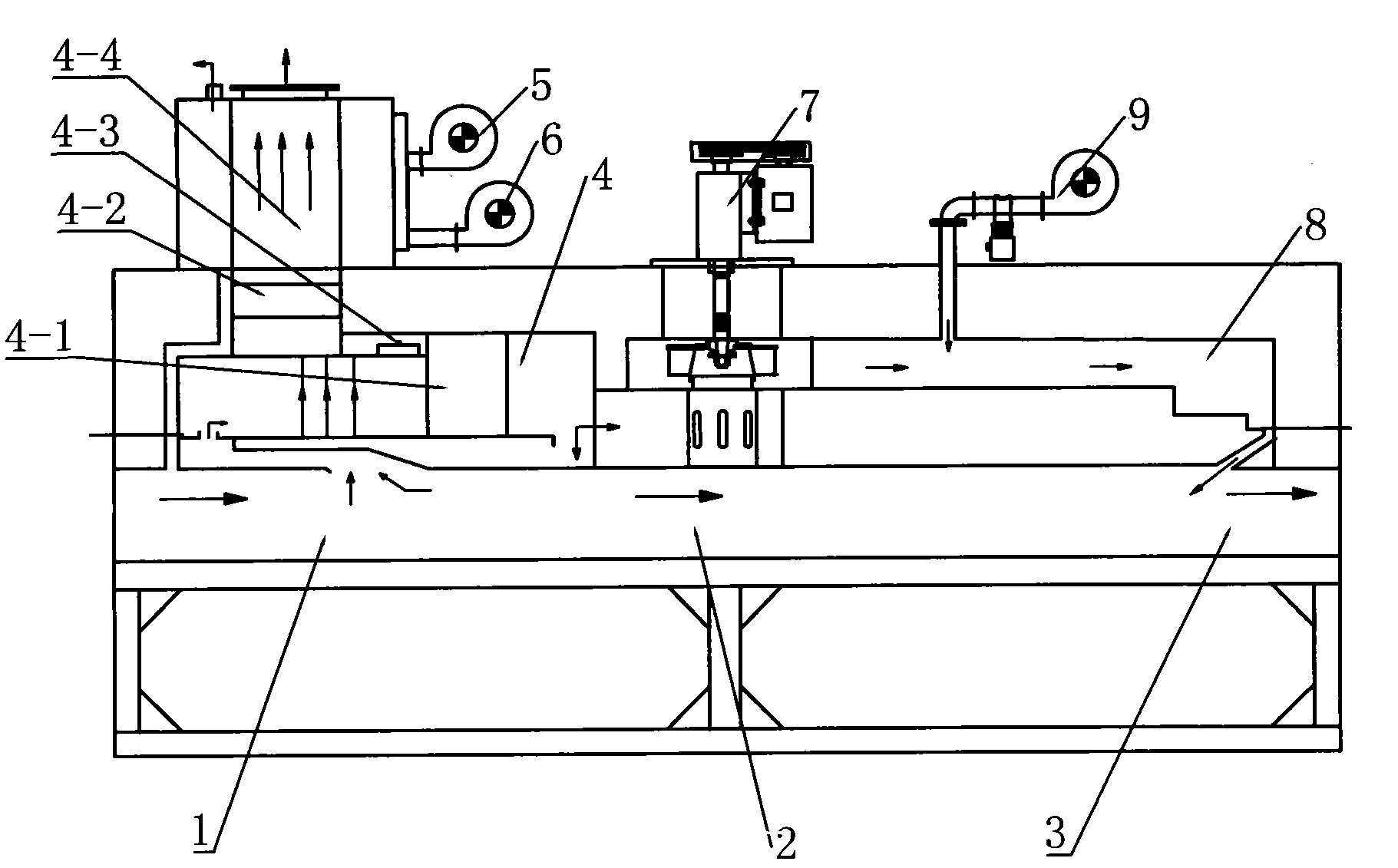

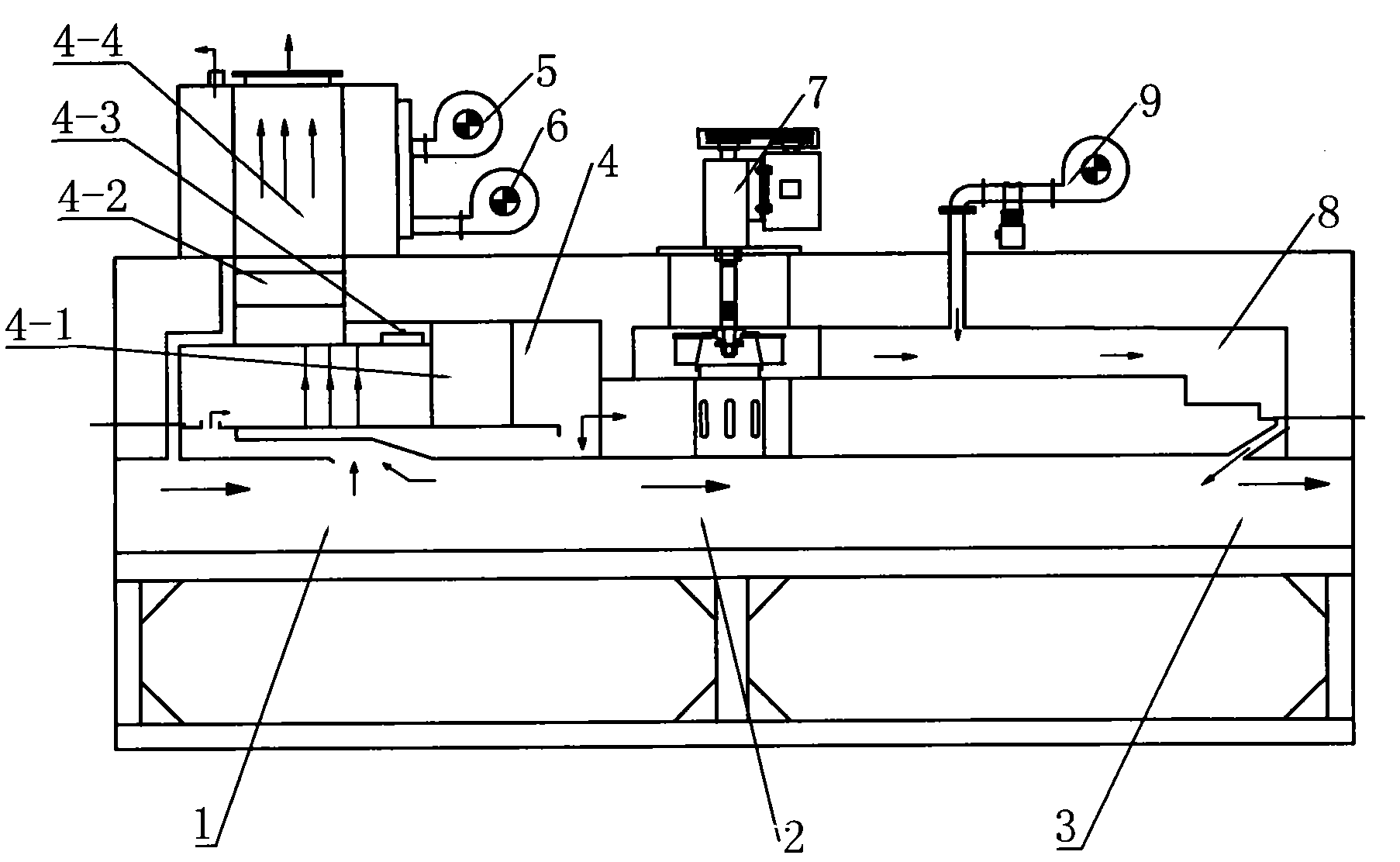

[0014] Such as figure 1 As shown, a hot air circulation and exchange enamelled oven of the present invention includes a furnace and a heat radiation device arranged therein. The furnace is sequentially provided with an evaporation zone 1, an assimilation zone 2 and a drying zone 3. There are catalytic combustion chambers 4 connected to each other. The catalytic combustion chambers 4 are provided with air inlets and outlets. The sides of the catalytic combustion chambers are connected with an air uniformity device 8. The air uniformity device is provided with passages that communicate with the drying area. The catalytic combustion chamber 4 comprises a primary catalytic chamber 4-1 and a secondary catalytic chamber 4-2 communicated with each other, an automatic damper 4-3 for controlling catalysis is arranged between the primary catalytic chamber and the secondary catalytic chamber, and the secondary catalytic chamber is provided with Exhaust channel 4-4. A heat exchange chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com