Monolithic integrated LED (light emitting diode) backlight and LCD (liquid crystal display) power supply driving system

A technology of power drive and single-chip integration, which is applied in the direction of light source, electric light source, lamp circuit layout, etc., can solve the problem of high chip price, and achieve the effect of high cost performance, good flexibility and strong driving ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

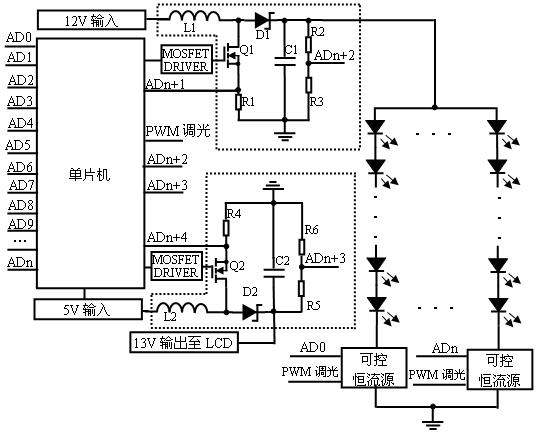

[0019] Example 1: see figure 1 , This monolithic integrated LED backlight and LCD power drive system, including the main control microcontroller, two MOSFET drive, two groups of L1, D1, Q1, C1, R1, R2, R3, L2, D2, Q2, C2, R4, A boost circuit composed of R5 and R6 and n Controllable constant current source, n It is a natural number, which is characterized in that the PWM signal output by a PWM module on the single-chip microcomputer is amplified by a MOSFET drive and then drives a set of booster circuits to boost the 12V input power to about 30V. n 9 LEDs connected in series with a constant current source; the PWM signal output by another PWM module on the single-chip microcomputer, after being amplified by another MOSFET drive, drives another set of boost circuits to boost the 5V input power to 13V , To provide power for LCD to save a power chip and reduce costs; the AD module on the microcontroller continuously detects the current and voltage of the two boost modules, and n LED ...

Embodiment 2

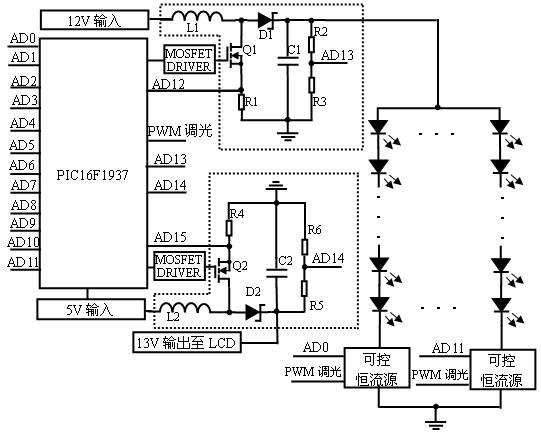

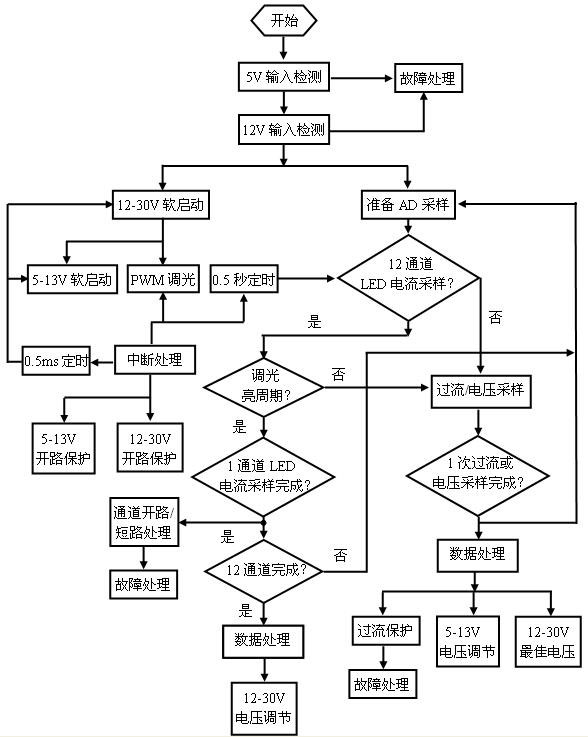

[0020] The second embodiment: this embodiment is basically the same as the first embodiment, and the special features are as follows: the specific circuit structure of this embodiment is as follows: figure 2 As shown, the main control single-chip microcomputer, MOSFET drive, 12-30V boost circuit composed of L1, D1, Q1, C1, R1, R2, R3, composed of L2, D2, Q2, C2, R4, R5, R6 5-13V boost circuit, 12-channel controllable constant current source and other components. The main control MCU adopts the PIC16F1937 of Microchip Technology Inc., and the working frequency is 32MHz. PIC16F1937 internal PWM2 module outputs PWM signal, boosts the input 12V DC power supply to about 30V, and drives 9 (string) × 12 (parallel) LEDs. The PWM1 module outputs another PWM signal, drives a 5-13V boost circuit, and boosts the input 5V DC power supply to 13V to provide power for the LCD. During the working period of the booster circuit, the AD on the microcontroller continuously detects the current and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com