Fractional order PID (proportion integration differentiation) control method of single input single output time lag system

A single-input single-output, time-delay system technology, applied to controllers with specific characteristics, electric controllers, etc. Issues such as ambiguous control domain boundary relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

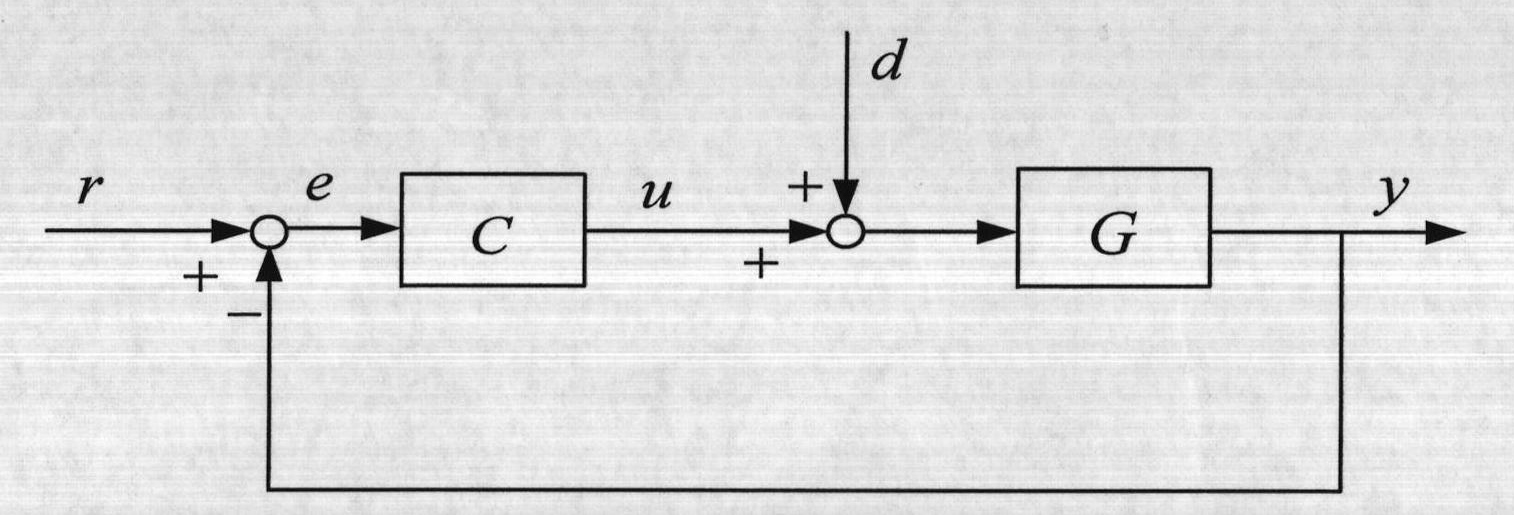

Method used

Image

Examples

Embodiment

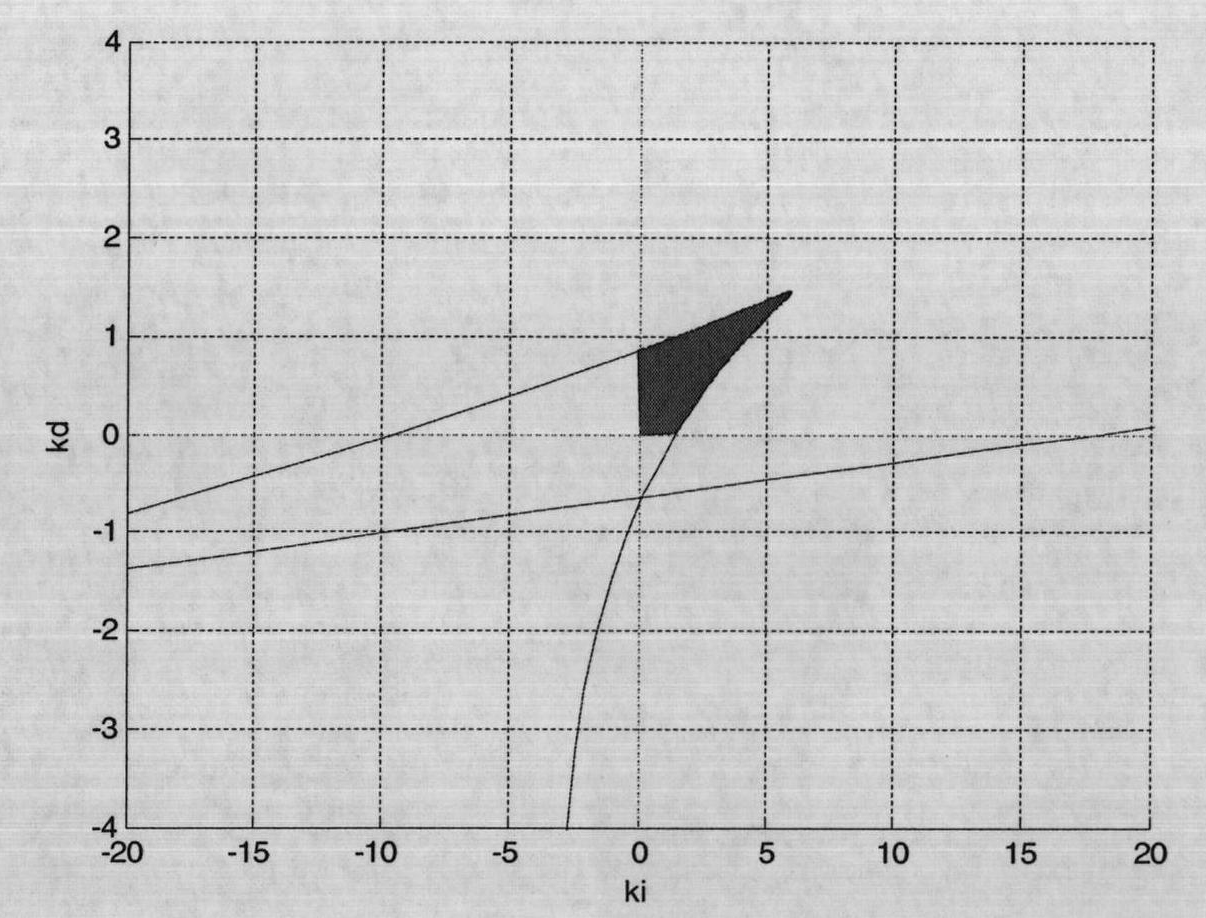

[0069] The control method proposed by the present invention is used in the automatic control system of the papermaking production process, and its purpose is to produce paper with constant weight. The design requirements are: ensure that the system response has no overshoot, the amplitude margin is in the interval [8db, 13db], the phase margin is greater than 60°, the adjustment time is less than 8s, and the rise time is less than 20s.

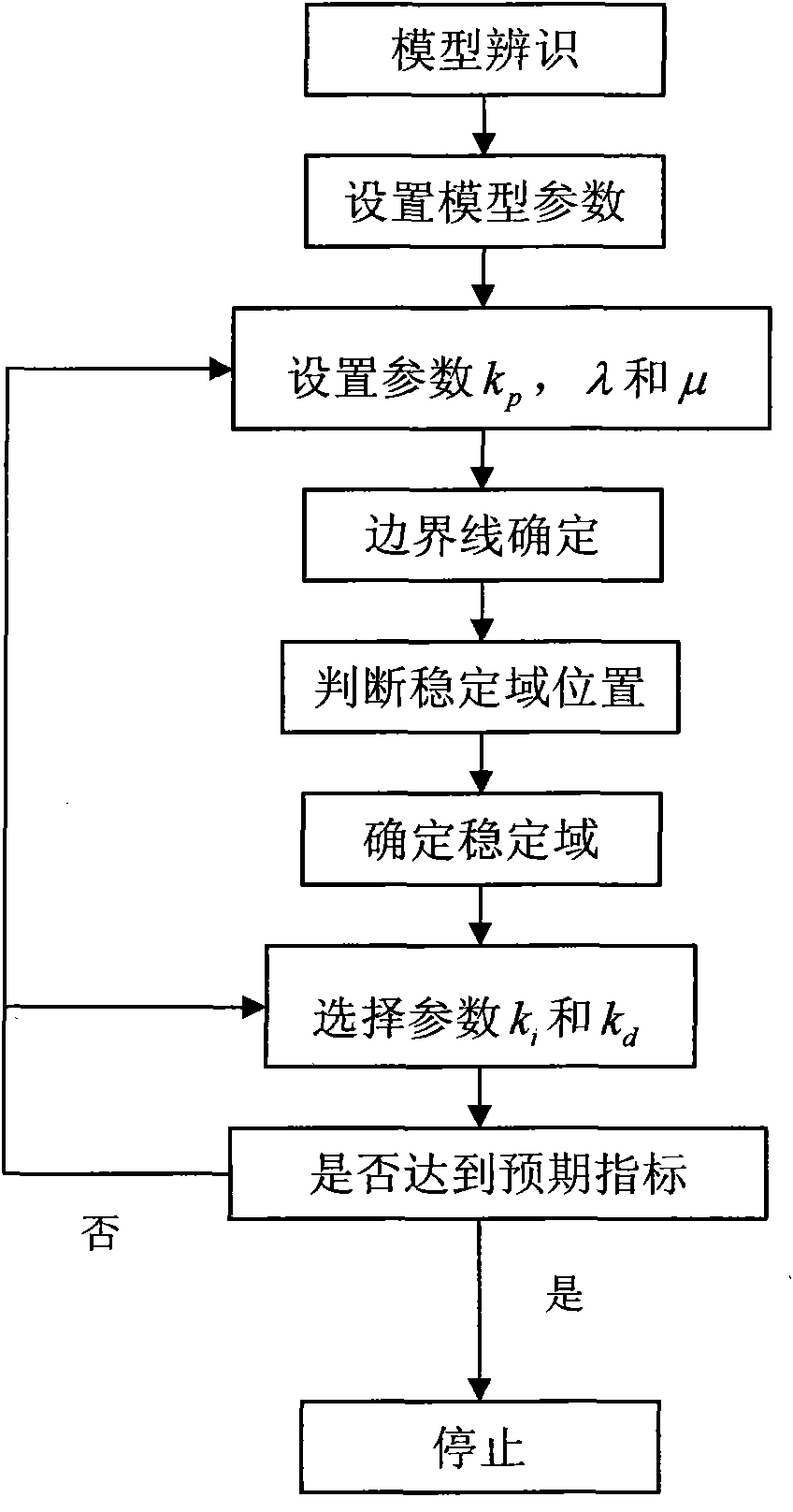

[0070] Next, the specific implementation steps are introduced:

[0071] (1) Use the paper production industrial control system to carry out automatic relay feedback identification on the control object—a typical fourdrinier paper machine. The result is that the dynamic model of the quantitative control paper machine is ie a 1 = 1, a0 = 1, α 1 = 1, α 0 =0,b 1 =0,b 0 = 1, β 0 =0, θ=1.

[0072] (2) According to the characteristics of the fractional order controller and whether λ+μ is equal to 2, two sets of parameter values are selected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com