High-accuracy visual coaxial optical alignment assembly system for miniature structural member

A technology for assembling systems and structural parts, applied in optics, optical components, instruments, etc., can solve the problems of difficult to solve visual occlusion problems, difficult to guarantee accuracy, low efficiency, etc., to meet the needs of real-time positioning, high alignment accuracy, The effect of reducing the amount of computation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention is described in further detail:

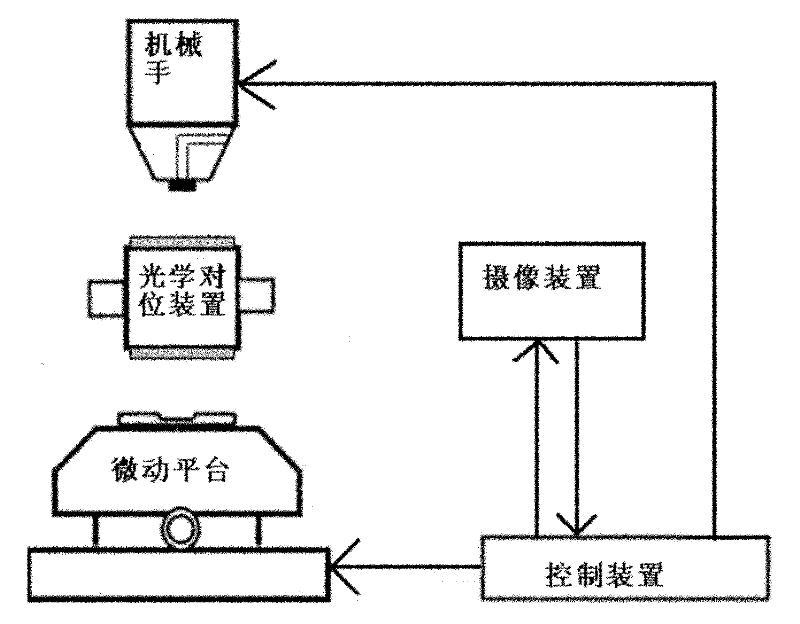

[0022] Such as figure 1 As shown, a high-precision visual coaxial optical alignment assembly system for micro-sized structural parts includes a manipulator, a light source, an optical alignment device, a micro-motion platform, a camera device, and a control device; wherein the camera device and the optical alignment device are located at On the same horizontal line, the manipulator and the micro-motion platform are respectively located above and below the optical alignment device;

[0023] The manipulator includes a suction head for absorbing the accessories to be attached, which can automatically realize the adsorption and release of the accessories to be treated under the control of the control device, and there is no adhesion between the manipulator and the accessories to be attached.

[0024] The light source includes the light source of the base part and the lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com