Measuring device and method of hearth velocity field of combustion boiler by using acoustic method

A boiler furnace and measuring device technology, applied in measuring devices, fluid velocity measurement, velocity/acceleration/impact measurement, etc., can solve problems such as difficult, difficult to give the aerodynamic characteristics in the furnace, heavy work, etc., to achieve low cost, Strong application feasibility, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

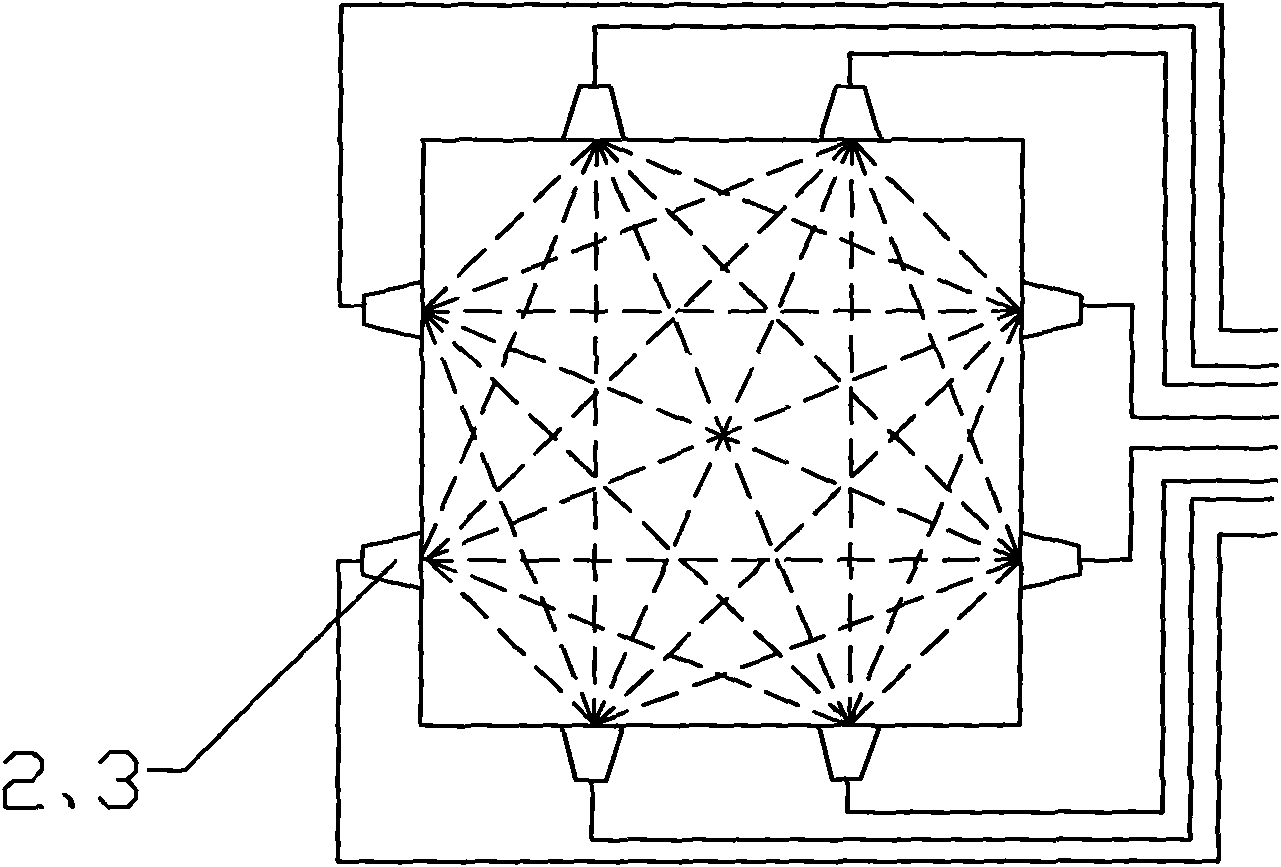

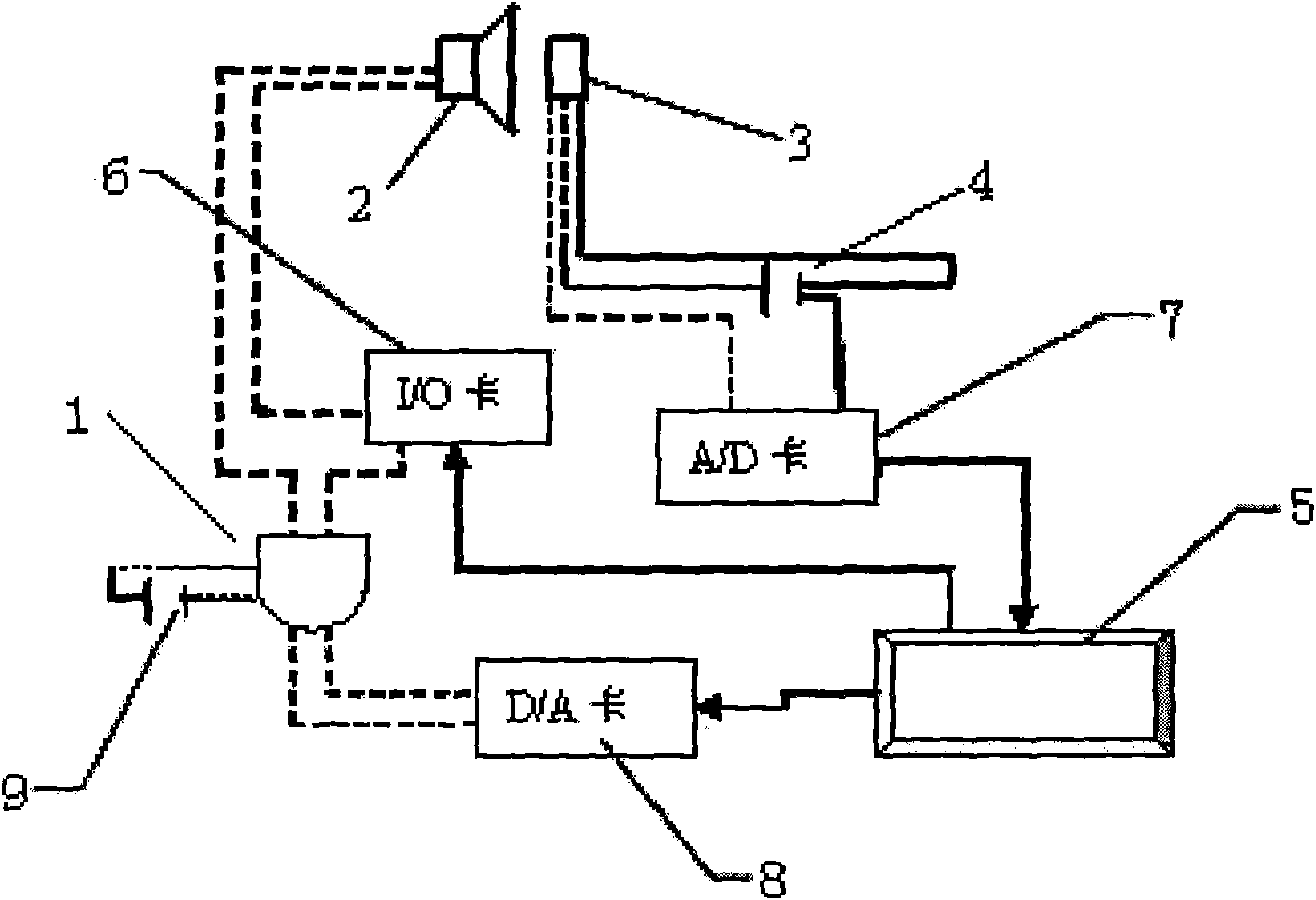

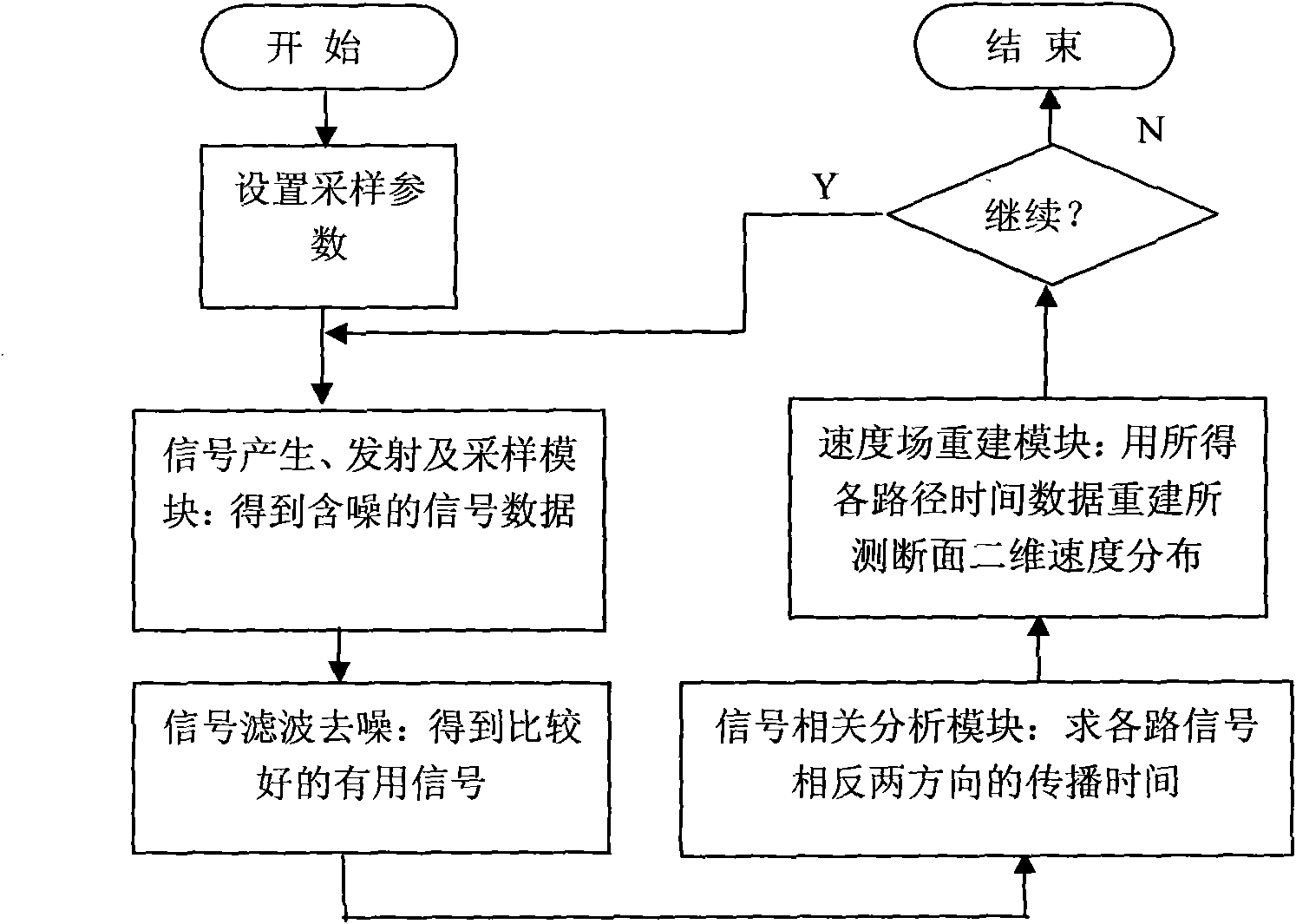

[0027] The present invention will be further described below in conjunction with accompanying drawing. figure 1 , 2 Among them, the characteristics of the measuring device for the velocity field of the acoustic combustion boiler furnace are: 8 groups of sound wave transmitters 2 and sound wave receivers 3 are evenly arranged on the four walls of the same section of the furnace, forming 24 interwoven sound wave propagation paths in the plane A plurality of acoustic wave transmitters 2 are respectively connected to the output end of the power amplifier 1 through the I / O card 6 of the computer, and the power supply ends of the plurality of acoustic wave receivers 3 are connected to the output end of the switching power supply 4 respectively, and its signal output end They are respectively connected to the computer 5 through the A / D card 7, and the computer 5 is connected to the corresponding audio input port of the power amplifier 1 through the D / A card 8. The sampling frequenci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com