Curved-jacked steel pipe section and jacking method

A technology of steel pipe jacking and pipe section, applied in the direction of pipe/pipe joint/pipe fitting, pipe laying and maintenance, mechanical equipment, etc., can solve the problems of inappropriateness, long welding time, complicated operation process, etc., to achieve easy operation and short construction period , the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

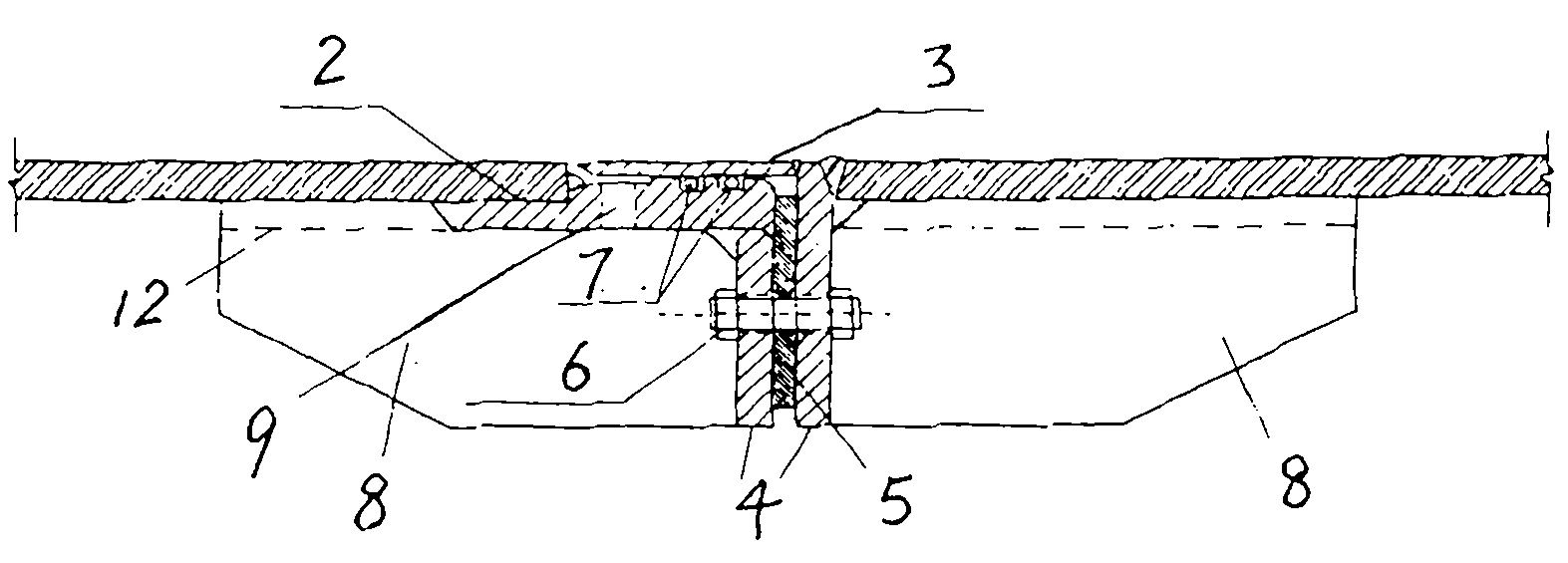

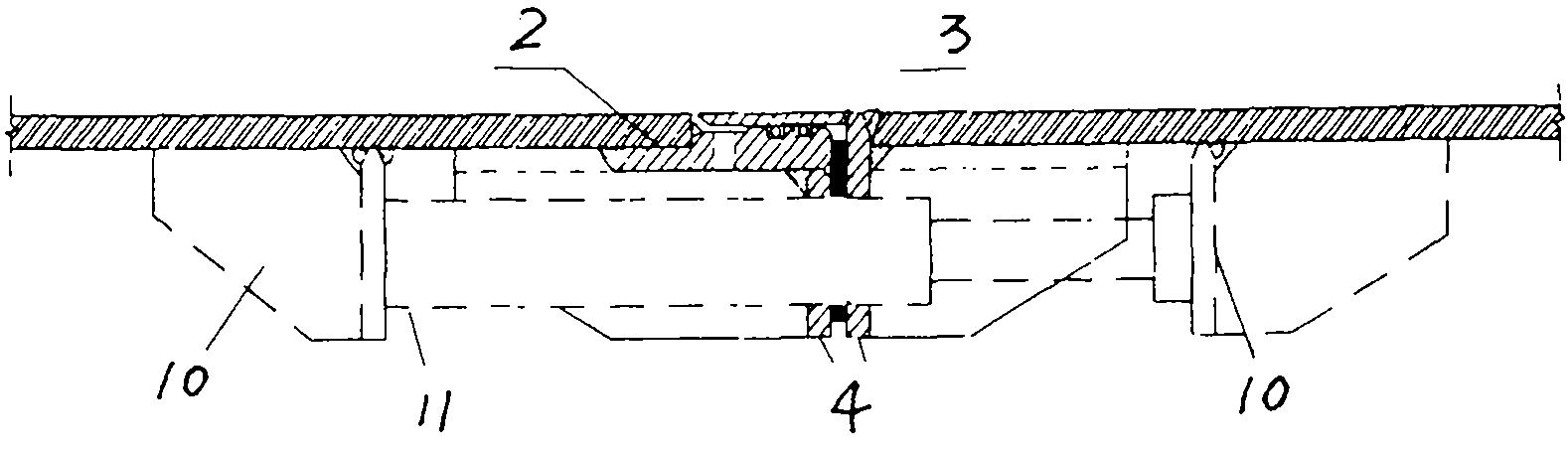

[0014] A curved steel pipe jacking joint is characterized in that sockets and sockets are respectively provided at both ends of the steel pipe joint. In view of the difference between the steel pipe and the reinforced concrete pipe, a stiffening ring is provided at the end of the socket and the socket respectively, and a longitudinal stiffening plate is arranged between the stiffening ring and the steel pipe to increase the circumferential stiffness of the steel pipe joint joint and reduce the steel pipe during jacking. For the deformation of the joint, the longitudinal stiffener is set to increase the stiffness of the steel pipe to bear the axial force.

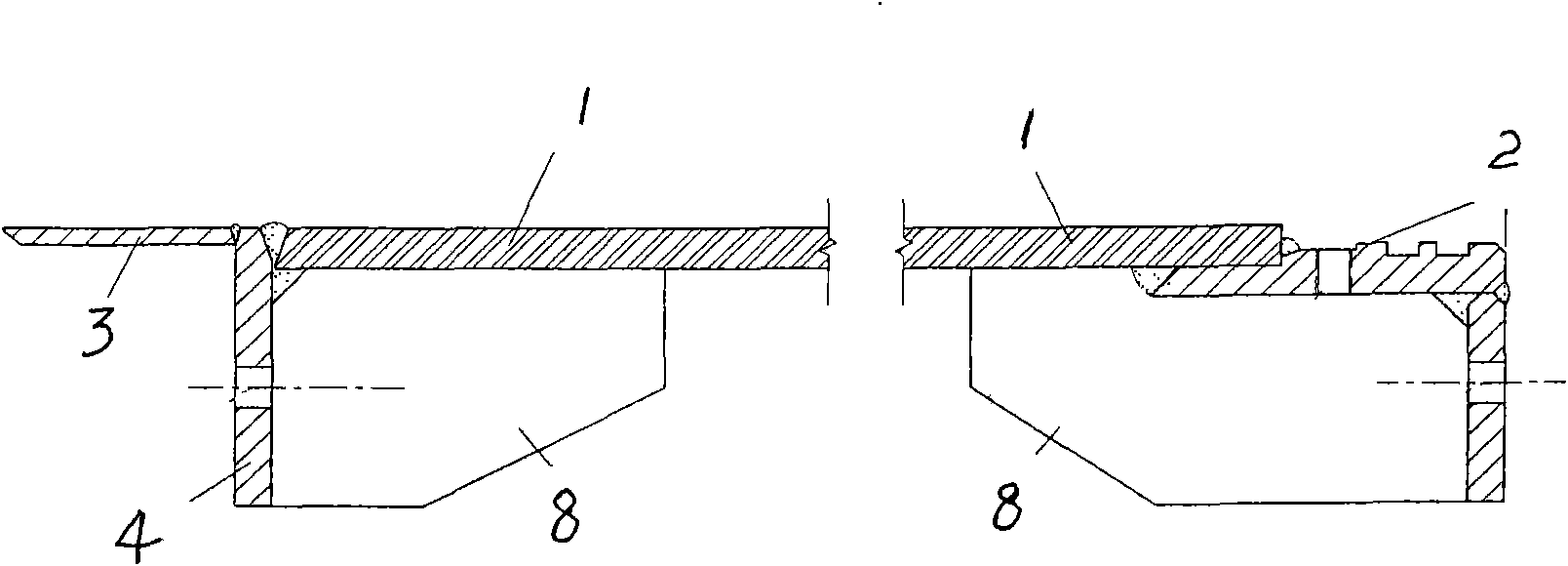

[0015] Such as figure 1 The shown pipe joint 1 of the present invention is about 2.5-5m in length, the pipe joint at one end of the pipe joint 1 is a socket 2 , and the other end of the pipe joint is a socket 3 . A stiffening ring 4 (also known as a ring stiffening plate) along the entire pipeline is provided at the socket ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com