Quickly loading booster cylinder and high-flow safety valve test device using same

A technology of large flow safety valve and test device, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system test, mining equipment, etc. Test the real working environment and slow loading speed of safety valve 1 to open quickly, so as to achieve the effect of infinite expansion of theoretical output flow, elimination of limitations, and small resistance loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

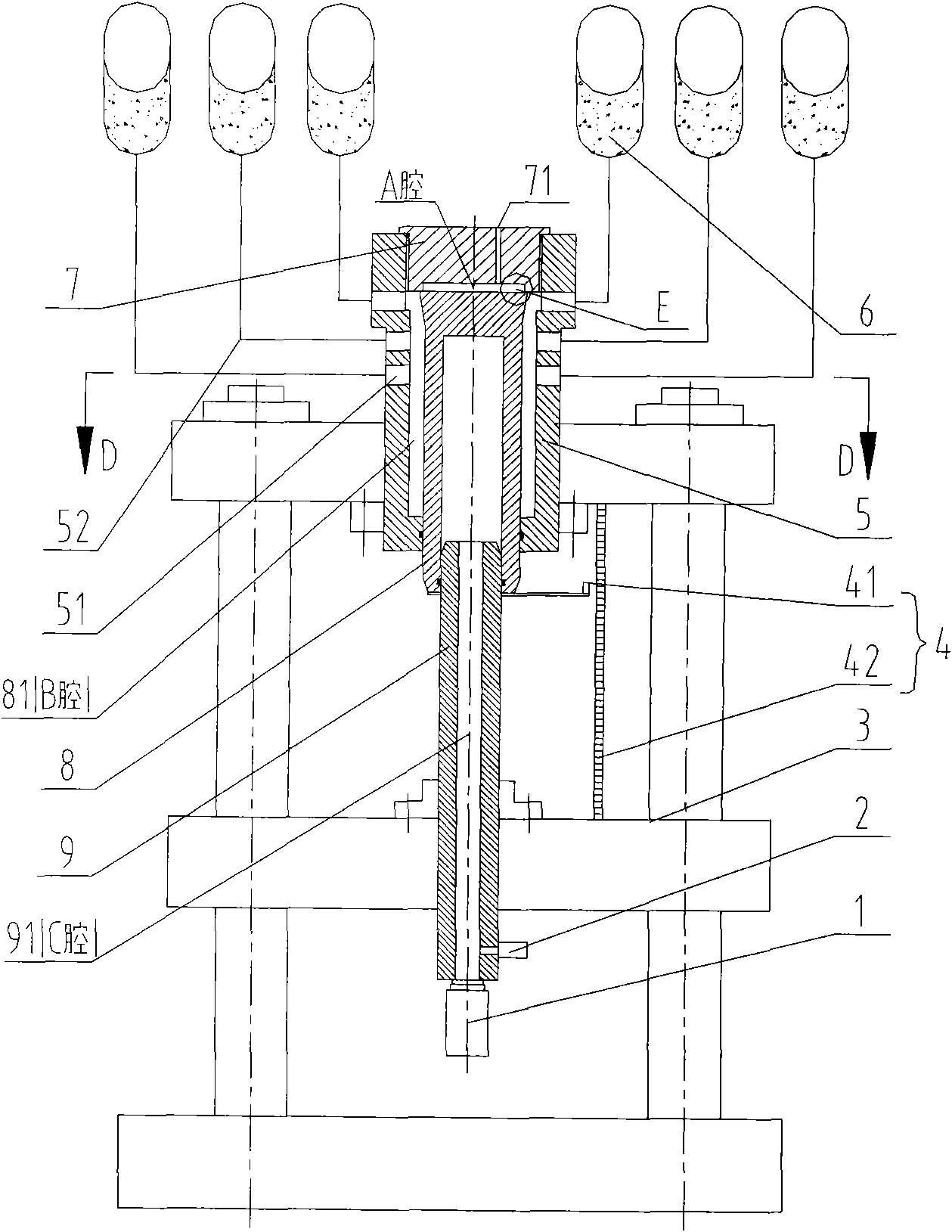

[0024] The present invention aims to provide a fast-loading pressurized cylinder with short output pressure rise time, small resistance loss, rapid opening, infinitely expandable output flow theory and low cost, and a large-flow safety valve test using the fast-loaded pressurized cylinder device.

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

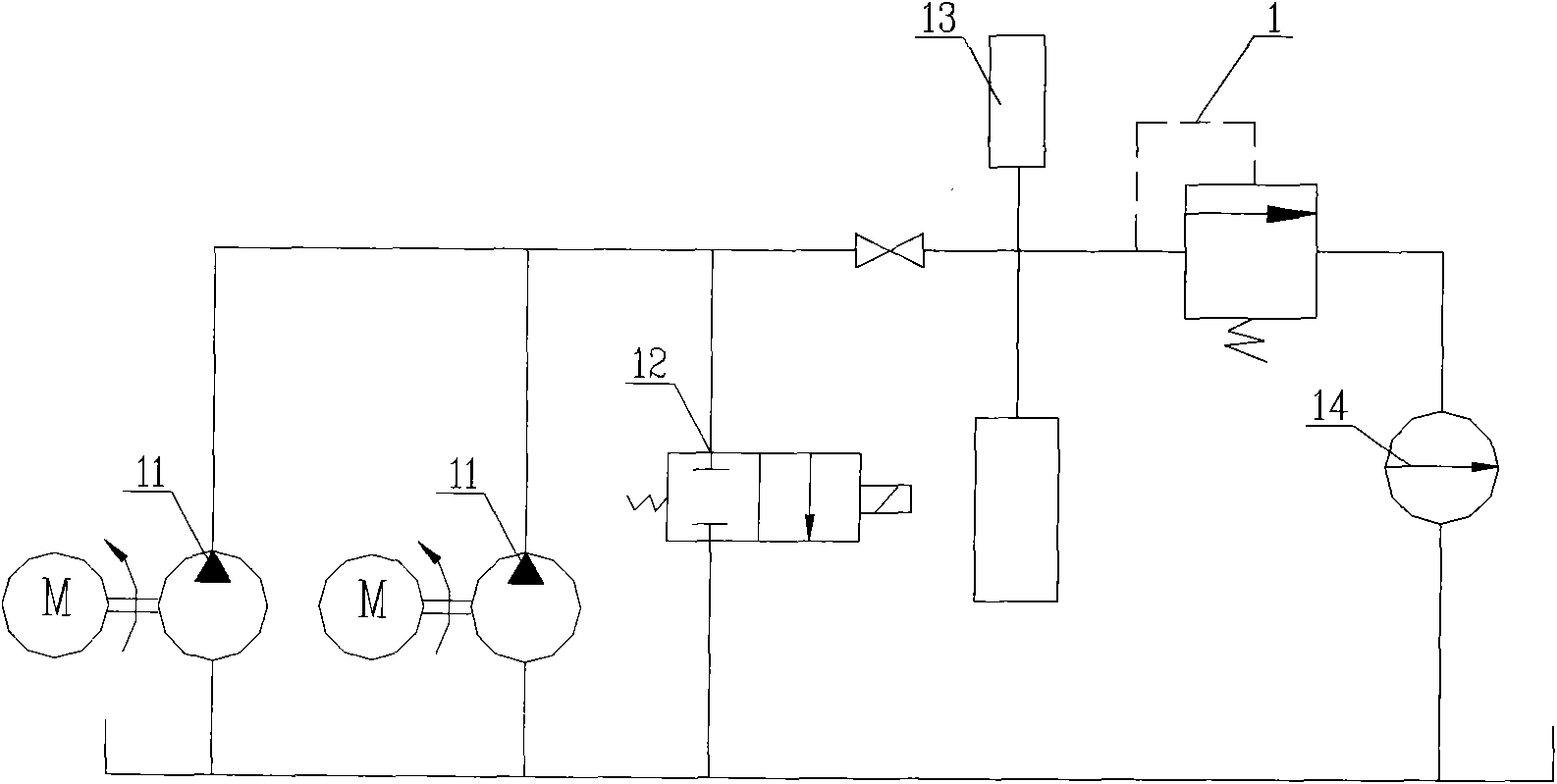

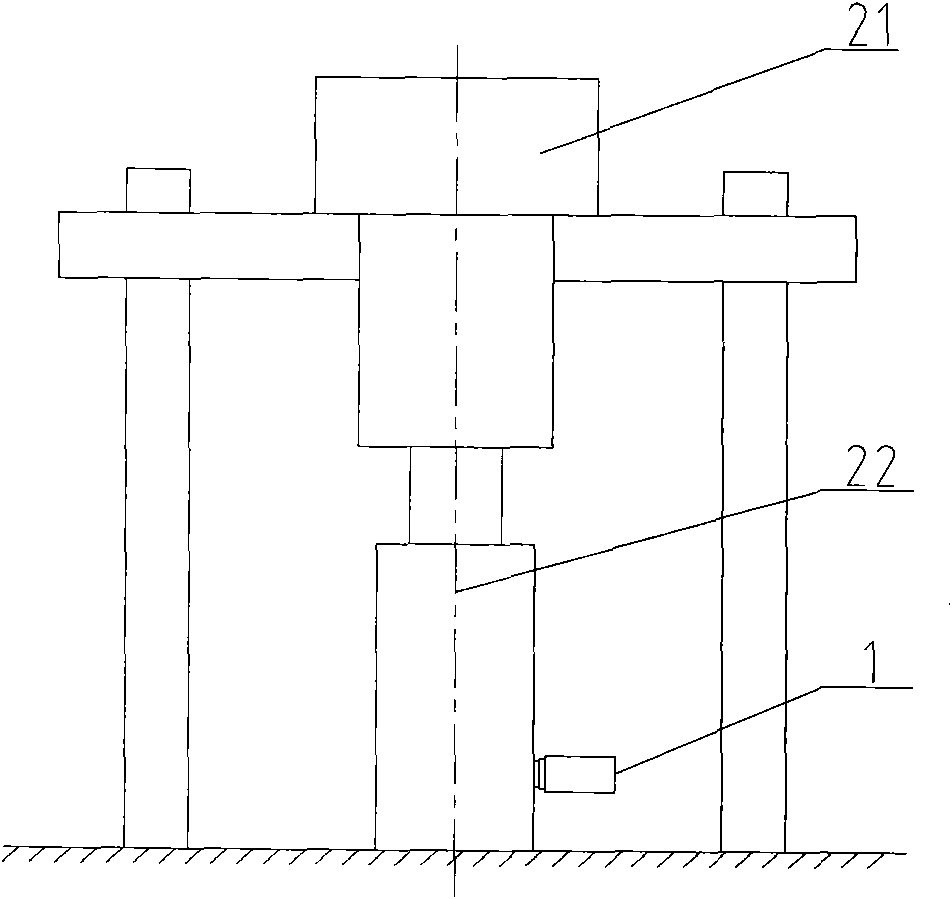

[0026] combine image 3 and Figure 4 As shown, the embodiment of the large-flow safety valve test device of the present invention includes a support body 3, and a fast-loading booster cylinder is provided on the support body 3, and the fast-loading booster cylinder includes a hydraulic cylinder 5, which is slidably arranged There is an upper plunger 8, a first hydraulic chamber 81 is arranged in the upper plunger 8, a lower plunger 9 is slidably arranged in the first hydraulic chamber 81, a second hydraulic chamber 91 is arranged in the lower plunger 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com