Underwater stand pipe vortex induced vibration inhibiter adopting rotatable cowling

A technology of rotating rectification and vortex-induced vibration, which is applied in the direction of fluid flow, drill pipe, casing, etc., to achieve the effects of increasing the scope of use, suppressing vortex-induced vibration, and simple and convenient manufacturing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

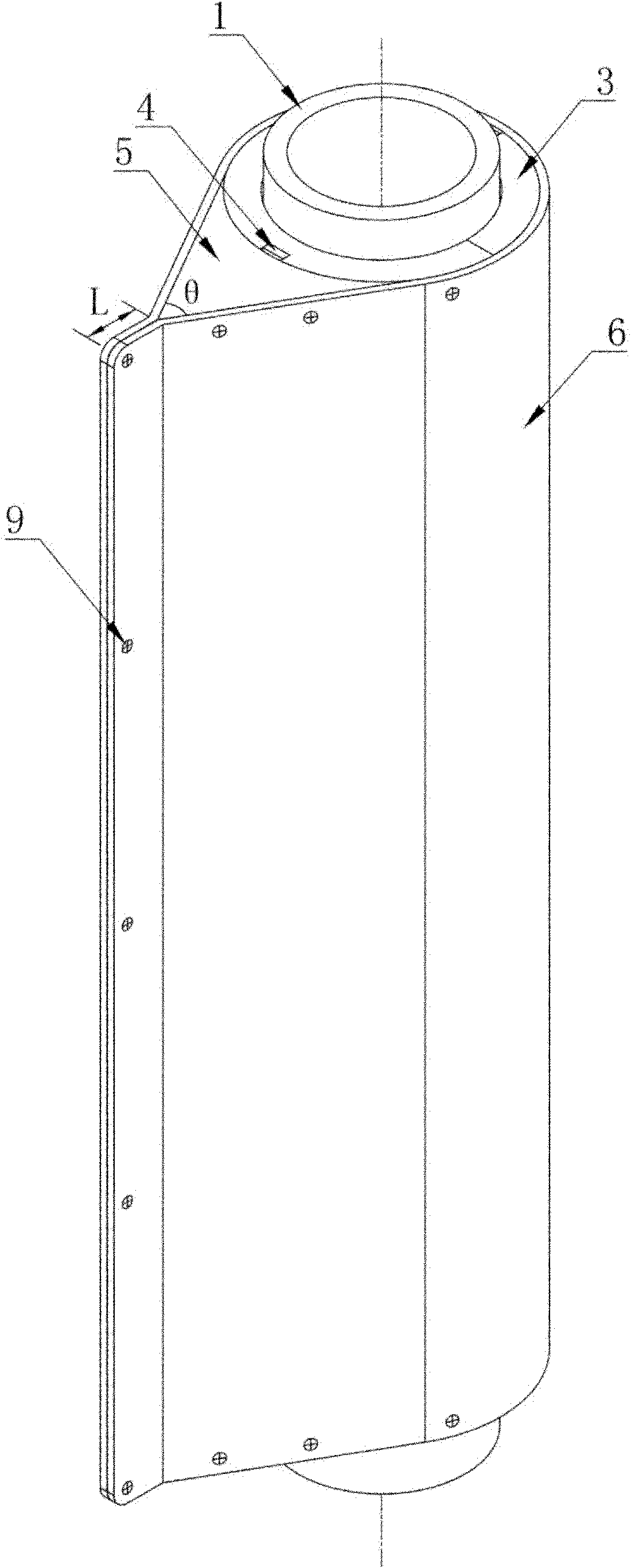

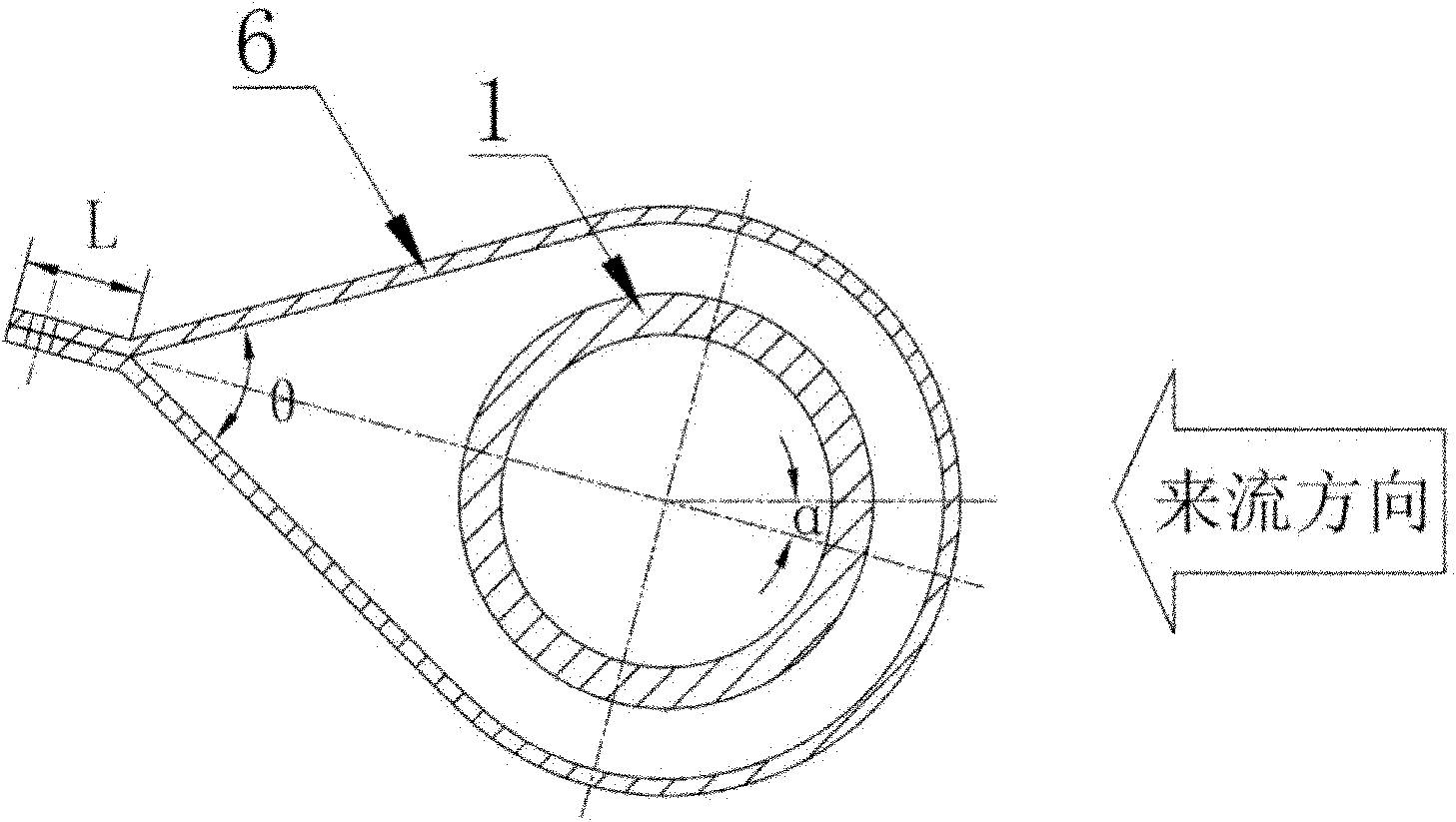

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention includes a pair of rotating modules, a fairing fixing pad 5 and a fairing 6 .

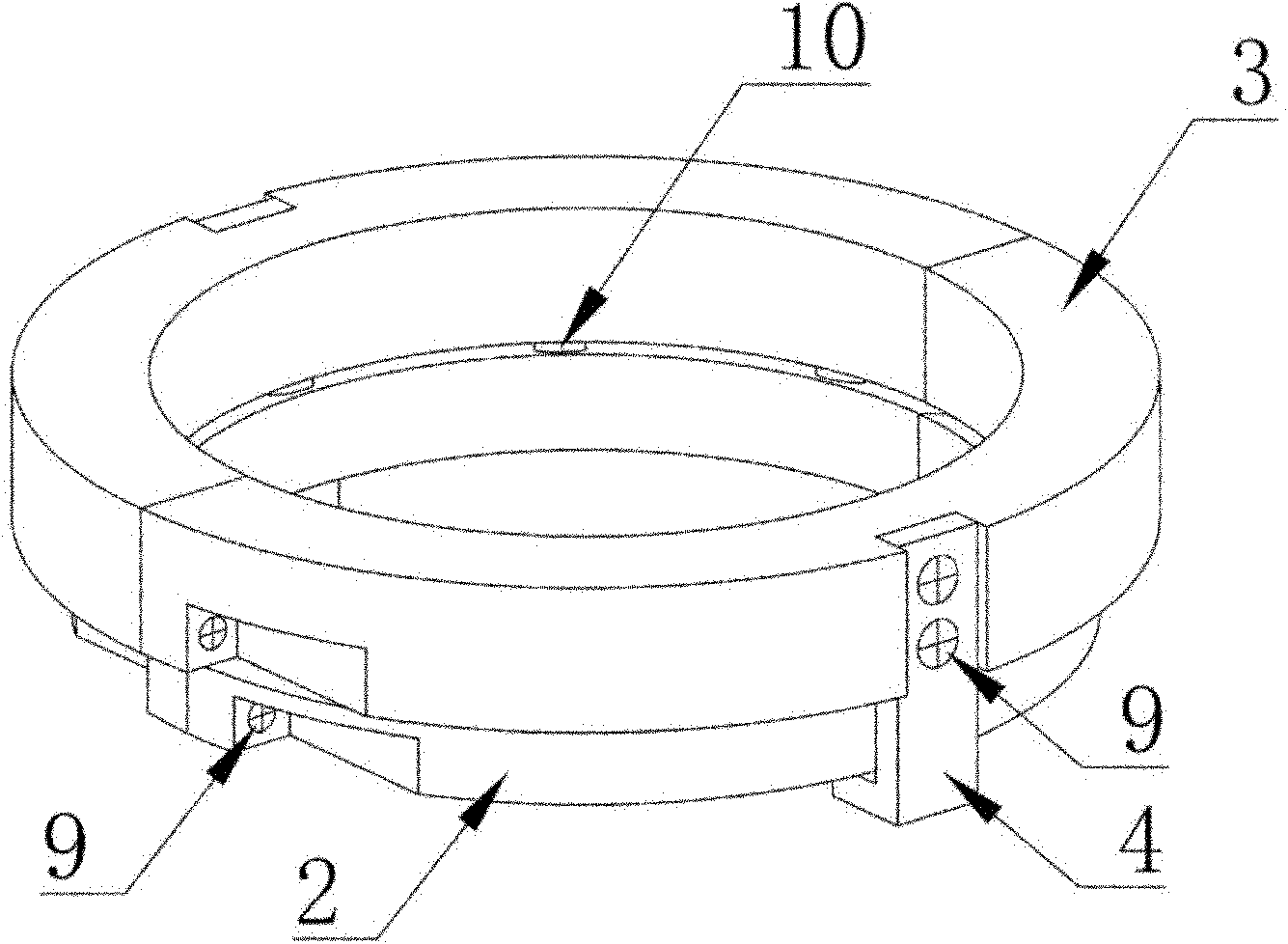

[0019] The rotary module includes a rotary module fixing part 2 , a rotary module rotating part 3 , a roller 10 and an axial stop piece 4 . The rotating module fixing part 2 is composed of symmetrical two-half ring steel components. The inner diameter of the rotating module fixing part 2 is equal to the outer diameter D of the standpipe 1, and the thickness of the inner and outer diameters is 0.12D to 0.14D. Sub slot 7. The rotating module fixing part 2 is sleeved on the riser 1 from both sides, and is connected and fixed with bolts 9 . The diameter of the roller 10 is 0.5 to 0.8 times of the thickness of the inner and outer diameter of the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com