Polycrystalline diamond compact

A polycrystalline diamond and composite sheet technology, applied in construction and other directions, can solve the problems of reducing the working life of the drill bit, thermal wear, poor cooling effect of PDC teeth, etc., to improve the cooling effect, enhance the thermal wear resistance, and reduce the weakening effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

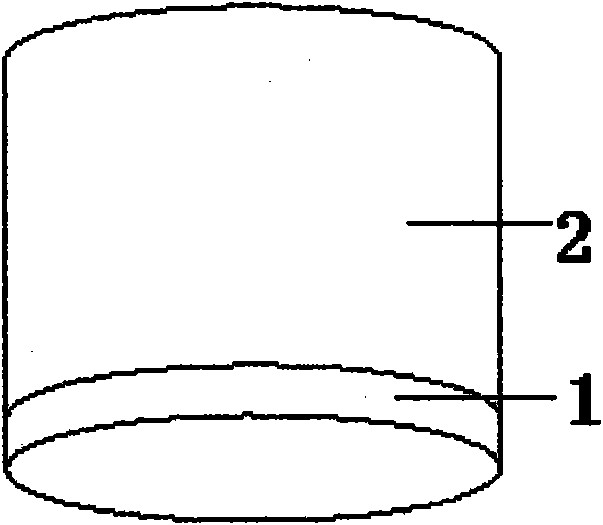

[0061] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0062] The following are examples of the shape and arrangement of the double grooves in the present invention:

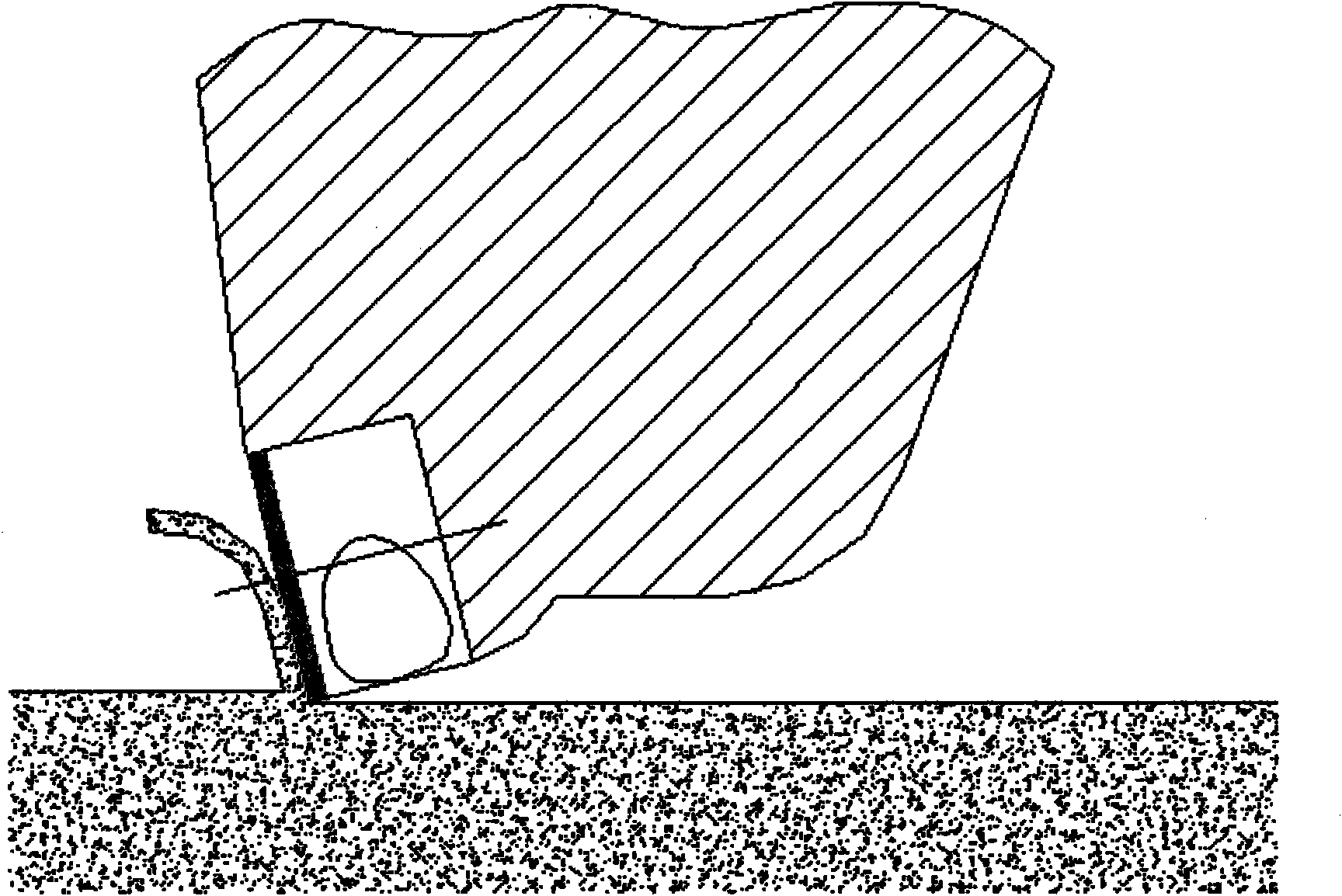

[0063] Part of the intersection line between the curved surface of the groove and the outer surface of the PDC composite sheet can be located on the side of the base body, and the other part can be located on the other outer surface of the base body.

[0064] The intersection lines between the curved surface of the groove and the outer surface of the PDC composite sheet can all be located on the side of the base body.

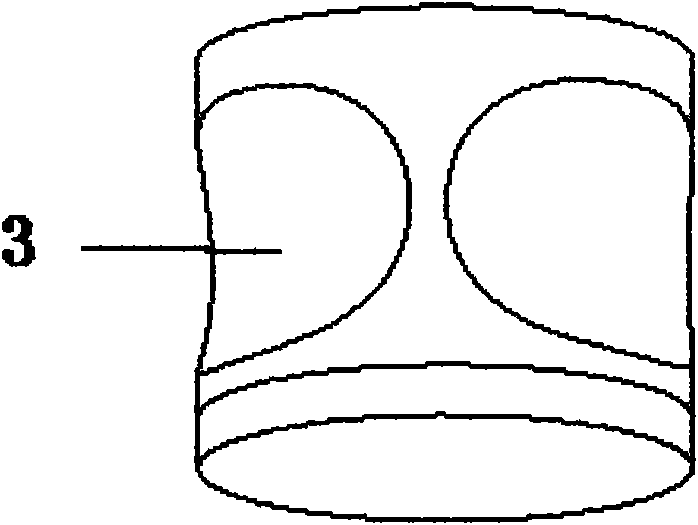

[0065] The inner concave surface of the double groove is a cylindrical surface, and the two grooves are symmetrically arranged on the composite sheet base body along the longitudinal direction, the transverse direction or the oblique direction.

[0066] The inner concave surface of the doub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com