Room temperature vulcanizing high-strength seamless large-scale rubber air sac and production technology thereof

A technology of rubber airbags and room temperature vulcanization, which is applied in water conservancy projects, sea area projects, embankments, etc., can solve the problems of complex manufacturing process, short service life, low pressure resistance, etc., and achieve good production stability, simple operation of production process, durable The effect of high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

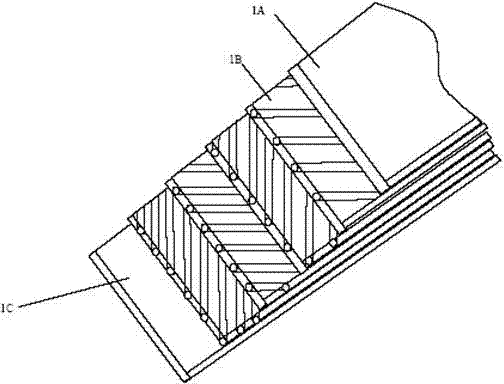

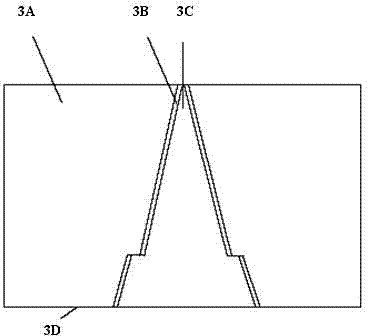

[0041] On a combined mold of 4×2m, according to the process described in the specific implementation method, the thickness of the canvas is 0.9mm, the tearing strength of a single fiber in the warp direction is 300N, and the tearing strength of a single fiber in the weft direction is 80N. When the airbag is not inflated, the flat size is 4×2m. Seal the wedge-shaped edge of the opening, pressurize 0.8MPa / 4 hours (holding pressure), and there is no leakage.

Embodiment 2

[0043] On the combined mold of 8×5m, according to the process described in the specific implementation method, the thickness of the canvas is 1.5mm, the tearing strength of a single fiber in the warp direction is 500N, and the tearing strength of a single fiber in the weft direction is 90N. When the airbag is not inflated, the flat size is 8×5m. Seal the wedge-shaped edge of the opening, pressurize 0.8MPa / 4 hours (holding pressure), and there is no leakage.

[0044] It can be seen from the pressure test results that the production process of the present invention is easy to operate, can meet the one-time molding and room temperature vulcanization of high-pressure, high-strength large-scale seamless rubber products, can exempt the harsh requirements of large-scale vulcanization tanks, and has good production stability; The large-scale rubber airbags produced have high compressive strength (the operating pressure is above 0.8MPa). It is mainly used for the lifting of pneumatic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com