Improved ring spinning frame and spinning process thereof

A ring spinning, improved technology, used in spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve problems such as poor quality, inability to meet high quality, diversification, and single yarn structure. , to achieve high strength, smooth appearance, good cloth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

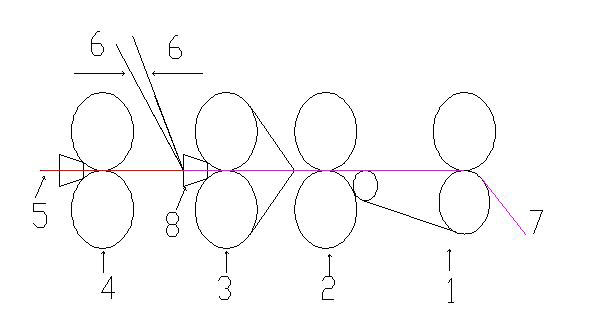

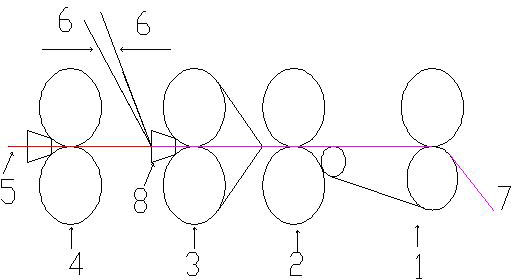

[0025] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes the rear roller 4, the middle roller 3, the second roller 2 and the front roller 1 arranged in sequence. The rear roller 4 and the middle roller 3 are provided with a feeding device 8 composed of a hanging spindle and a bell mouth, and the rear roller is controlled. The servo motor of roller 4 is equipped with a variable speed intelligent controller, which is connected to the encoder installed on the front roller 1; the output port of the front roller 1 is equipped with a special-shaped suction groove and the inside is in a negative pressure state. The special-shaped tube is covered with a grid ring, and the grid ring is pulled by the roller.

[0026] Taking three roving feeding as an example, one ornamental yarn 5 is fed intermittently from rear roller 4, two base yarns 6 are fed continuously from middle roller 3, drafted by front roller 1 and second roller 2 in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com