Method for preparing ferrous nitrate solution by adopting liquid-solid phase moving bed reaction device

A reaction device, a technology of ferrous nitrate, applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve the problems of high local concentration of nitric acid, difficult to clean, easy to produce high-valent iron, etc. The effect of reducing the formation of high-valent iron and by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method includes the following steps:

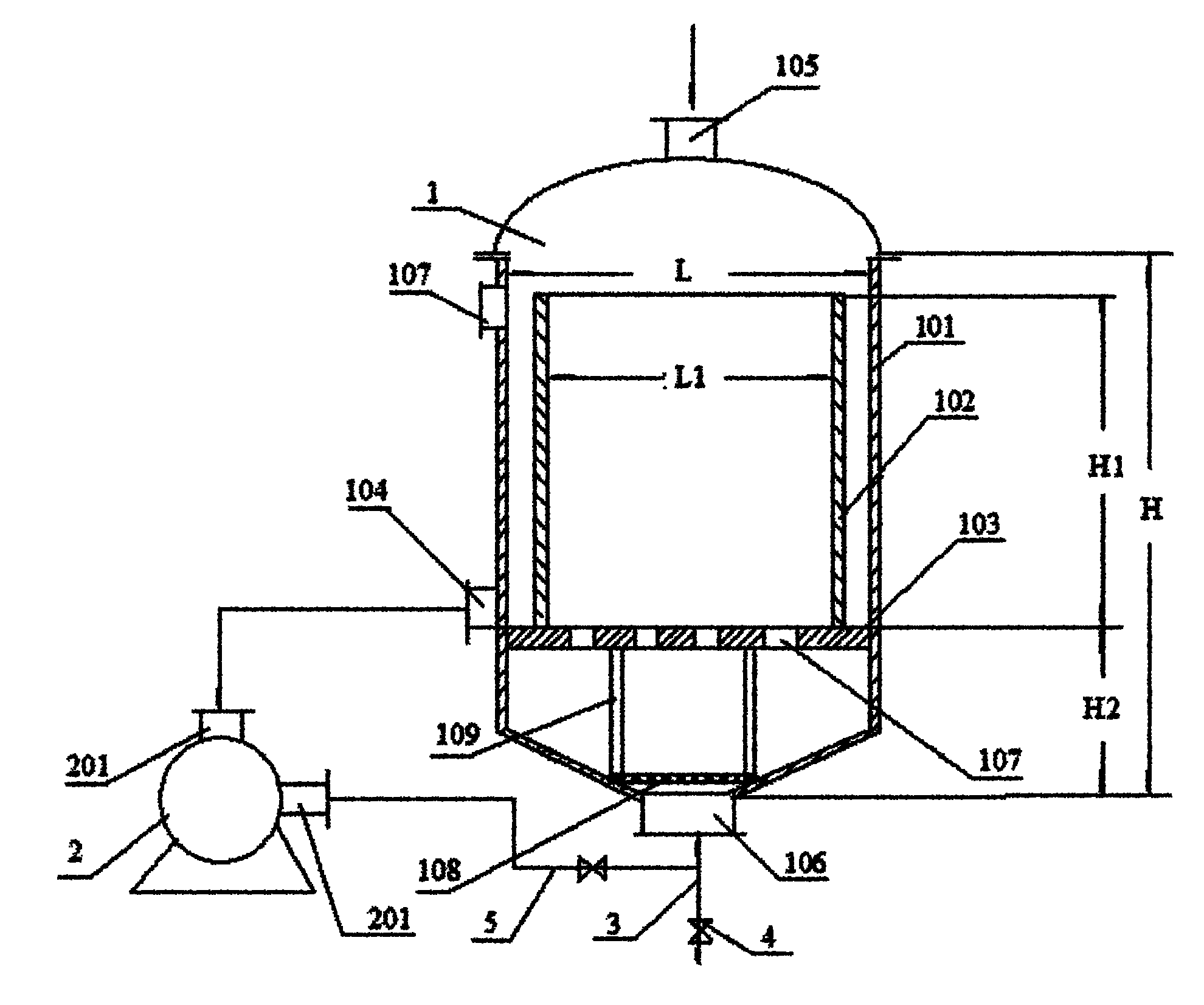

[0037] Place the iron sheet in the inner cylinder 102, and then add water to the inner cylinder 102 through the material inlet 105 until it overflows into the jacket formed by the shell 101 and the inner cylinder 102, so that the liquid level in the jacket is higher than the circulation outlet 104. The diameter is 50-400mm, and then the circulating pump 2 is started, and the material is drawn out from the circulation outlet 104 and sent to the shell 101 through the material outlet 106. At the same time, nitric acid is added to the acid inlet 107 at the top of the shell 101 to circulate to the pH of the ferrous nitrate solution The value is 1 to 5, preferably 3.2 to 3.5, the concentration of the ferrous nitrate solution is 8-15g / 100ml, preferably 11-13g / 100ml, to obtain a clear blue-green solution, which is the product ferrous nitrate solution, from the material outlet 106 Send out

[0038] From starting the circulating ...

Embodiment 1

[0045] use figure 1 The liquid-solid phase moving bed reaction device produces ferrous nitrate solution.

[0046] The structural parameters of the reactor are as follows:

[0047] The height H of the housing 101 is 3.5 meters, the diameter L is 3 meters, and the ratio of the height H to the diameter L of the housing 101 is 1:0.86;

[0048] The height H1 of the inner cylinder 102 is 3.2 meters, the diameter L1 is 2.6 meters, and the ratio of H1 to L1 is 1:0.81;

[0049] The ratio of the diameter L of the housing 101 to the diameter L1 of the inner cylinder 102 is 1:0.87;

[0050] The distance H2 between the partition plate 103 and the material outlet 106 is 0.3 meters;

[0051] The diameter of the distribution holes 107 is 50mm, and the opening rate is 20%;

[0052] The preparation method is as follows:

[0053] Put 2500 kg of iron sheet in the inner cylinder 102, and then add 17,100 kg of water into the inner cylinder 102 through the material inlet 105 until it overflows into the jacket f...

Embodiment 2

[0061] The structural parameters of the reactor are as follows:

[0062] The height H of the housing 101 is 4.2 meters, the diameter L is 3.4 meters, and the ratio of the height H to the diameter L of the housing 101 is 1:0.81;

[0063] The height H1 of the inner cylinder 102 is 3.0 meters, the diameter L1 is 3.0 meters, and the ratio of H1 to L1 is 1:0.93;

[0064] The ratio of the diameter L of the housing 101 to the diameter L1 of the inner cylinder 102 is 1:0.88;

[0065] The distance H2 between the partition plate 103 and the material outlet 106 is 1.2 meters;

[0066] The diameter of the distribution holes 107 is 5mm, and the opening rate is 70%;

[0067] The preparation method is as follows:

[0068] Put 1,100 kg of iron sheet in the inner cylinder 102, and then add 22,000 kg of water into the inner cylinder 102 through the material inlet 105 until it overflows into the jacket formed by the shell 101 and the inner cylinder 102, so that the liquid level in the jacket is higher than ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com