Liquid ejecting apparatus and method of controlling liquid ejecting apparatus

A technology of jetting device and liquid jetting head, which is applied in printing and other directions, can solve the problems of complicated ink control and larger size of recording head, and achieve the effects of reducing flying speed difference, preventing deviation of attachment position, and reducing crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, embodiments for carrying out the present invention will be described with reference to the drawings. In addition, in the following examples, various limitations are made as preferred specific examples of the present invention, but the scope of the present invention is not limited to these forms unless there is a description that specifically limits the content of the present invention in the following description. In addition, below, an inkjet recording device (hereinafter referred to as a printer) will be described as an example of the liquid ejecting device of the present invention.

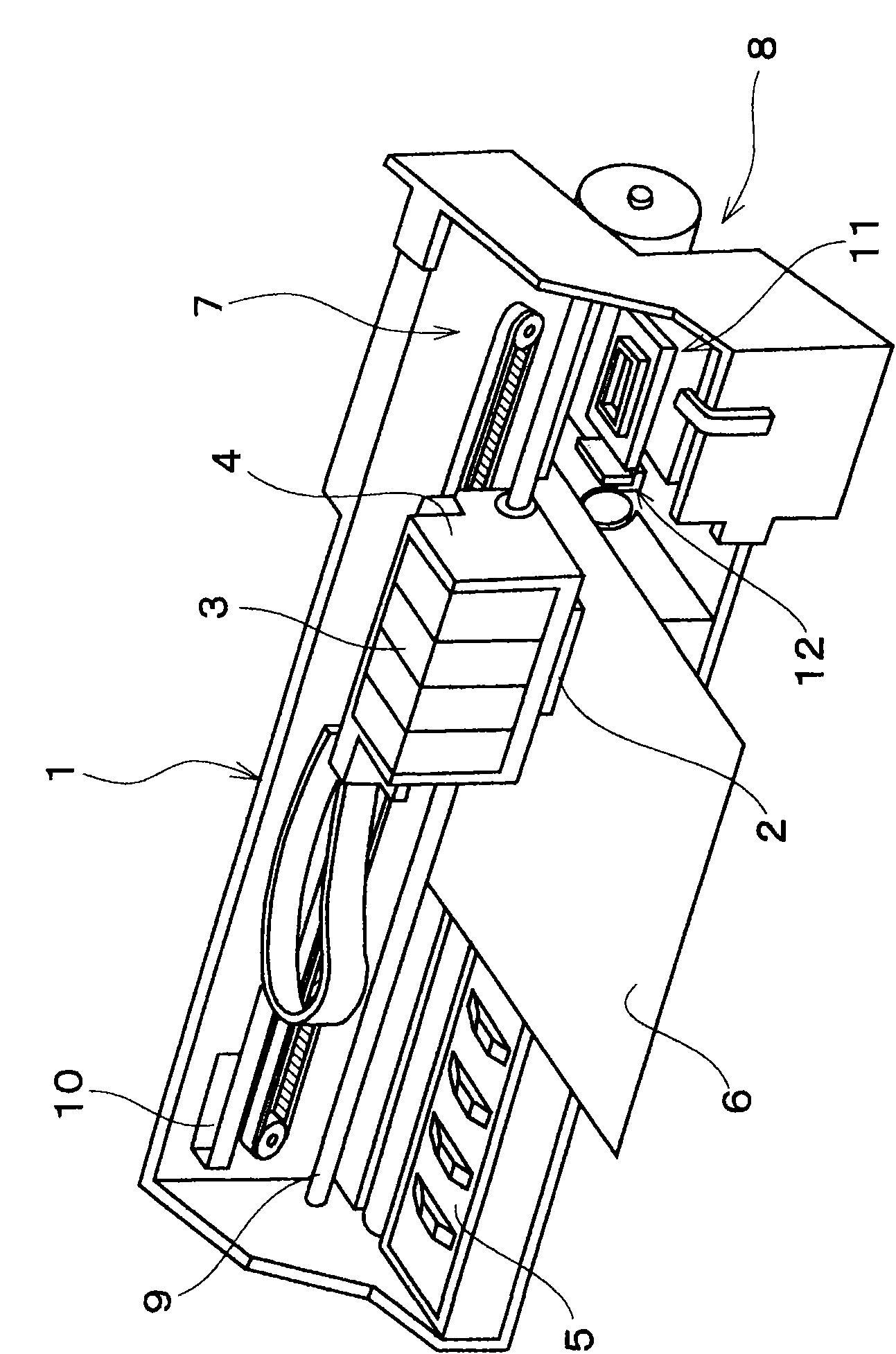

[0046] figure 1 It is a perspective view of the configuration of the printer 1 . This printer 1 generally includes: a carriage 4 on which a recording head 2 is installed as a liquid ejection head and an ink cartridge 3 is detachably installed; a platen 5 is arranged below the recording head 2; A carriage moving mechanism 7 (a kind of moving unit) that reciprocates in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com