Double-swing cutter head driven by alternating-current permanent-magnet synchronous inner rotor torque motor

A torque motor and permanent magnet synchronous technology, which is applied in the field of machine tools, can solve problems such as complex installation, large additional moment of inertia, and gaps in transmission, and achieve the effects of compact structure, increased adaptability and flexibility, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

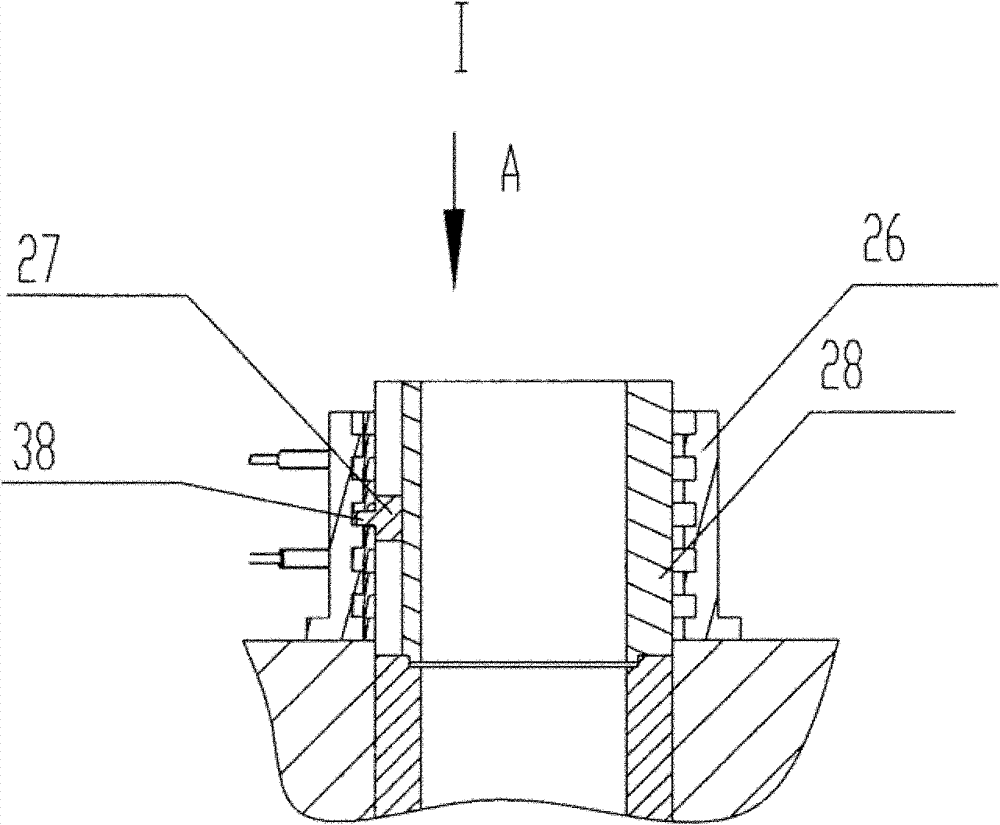

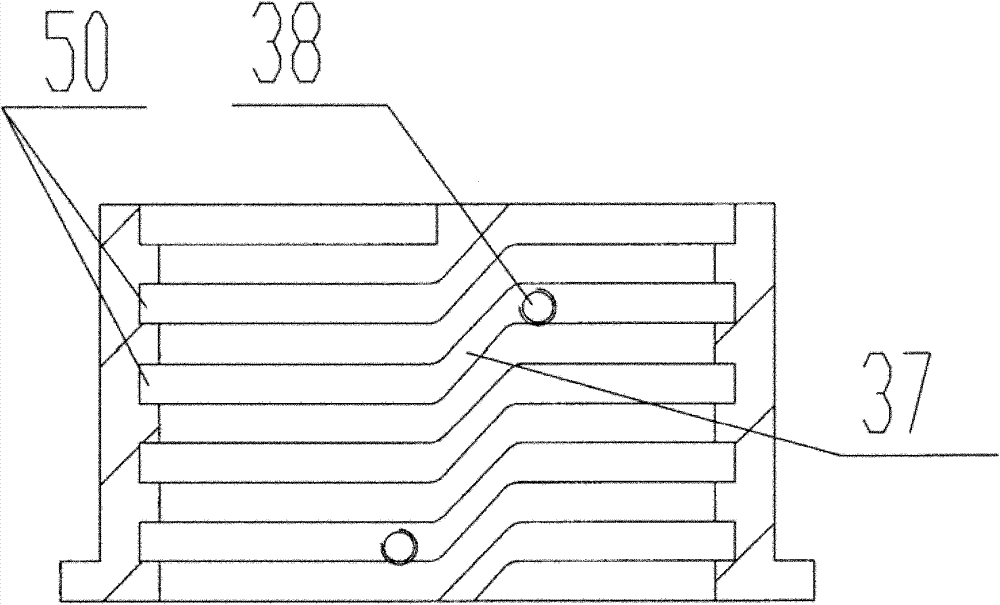

[0037] Such as figure 1 As shown in -9, the present invention is driven by an AC permanent magnet synchronous inner rotor torque motor. The A-axis exchangeable AC-axis double pendulum milling head is divided into upper and lower parts by the end gear plate 8, and the upper part is C-axis, which can be rotated vertically. The axis rotates; the lower part is the A axis, which can swing around the vertical axis. Through the linkage of A and C, the profiling processing of complex curved surfaces is realized. The A and C axes are respectively equipped with exchange connection interfaces to realize the automatic exchange of the A axis. The specific structure is as follows:

[0038] The upper part is the C-axis, which is jointly driven by two inner rotor torque motors. The rotors of the two AC permanent magnet synchronous inner rotor torque motors 15 are fixed to the mandrel 14 by screws, and the mandrel 14 and the C-axis base 18 are positioned and passed through screw connection. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com