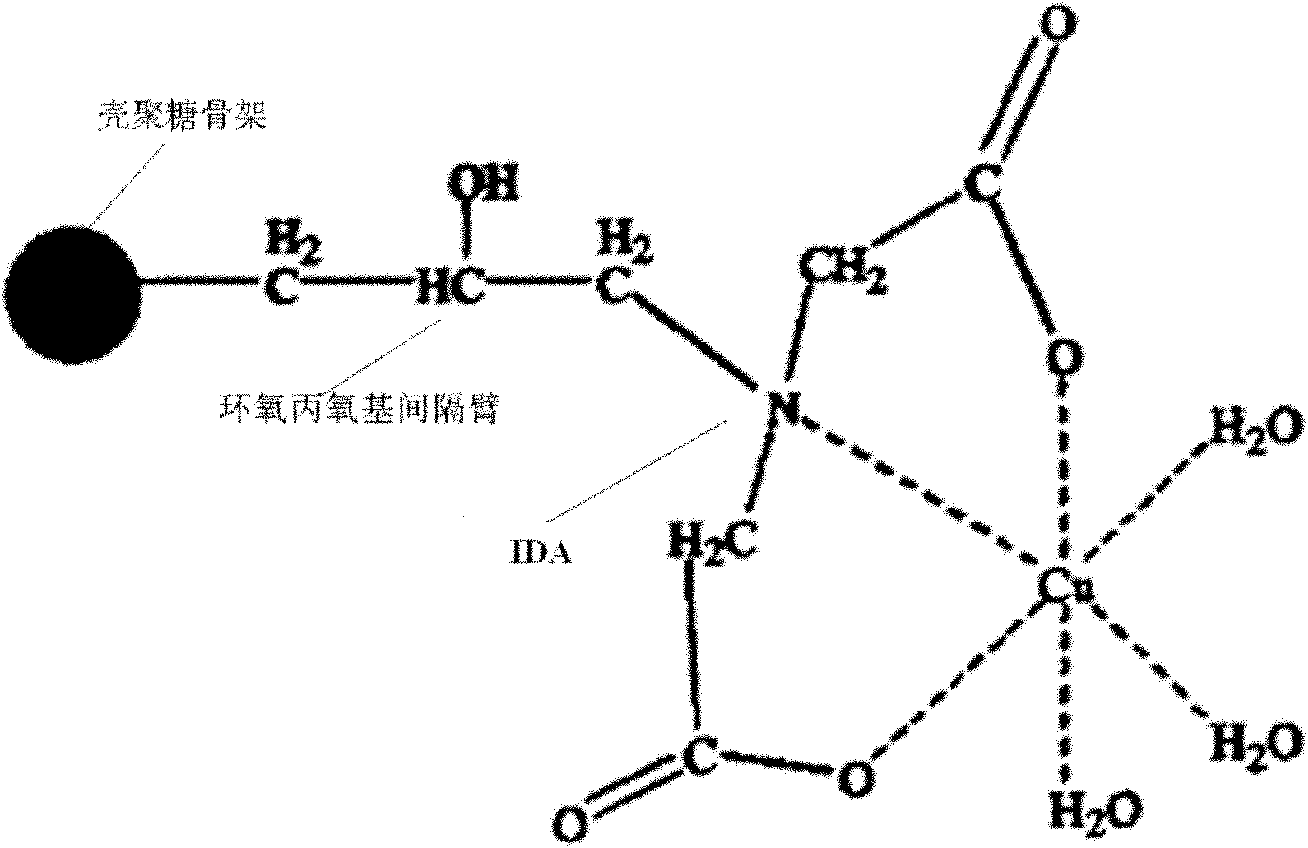

Method for preparing chitosan separation medium suitable for protein purification

A separation medium and protein purification technology, which is applied in the field of natural polymer materials, can solve the problems of low adsorption capacity and unstable conditions of chitosan separation medium, and achieve the solution of metal ion leakage, process stability and reproducibility Good, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

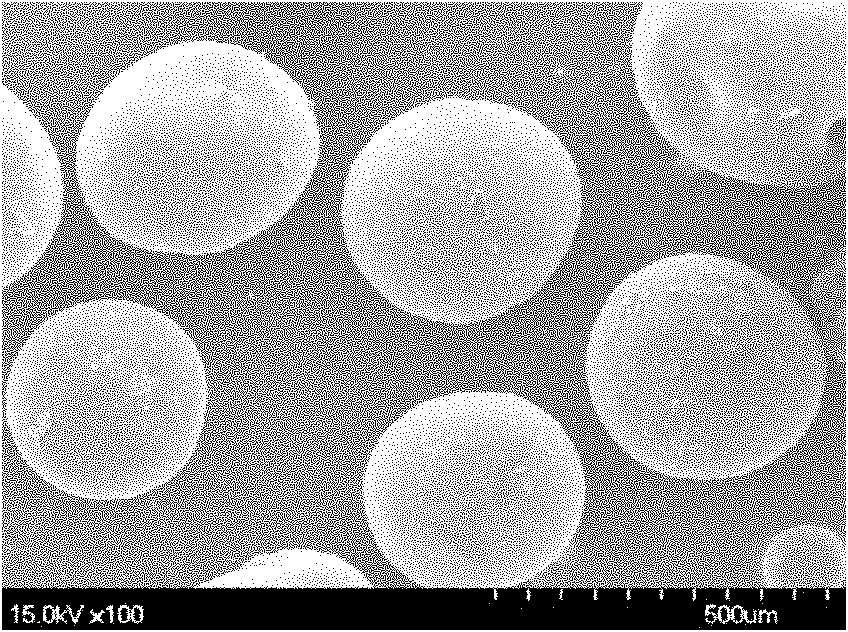

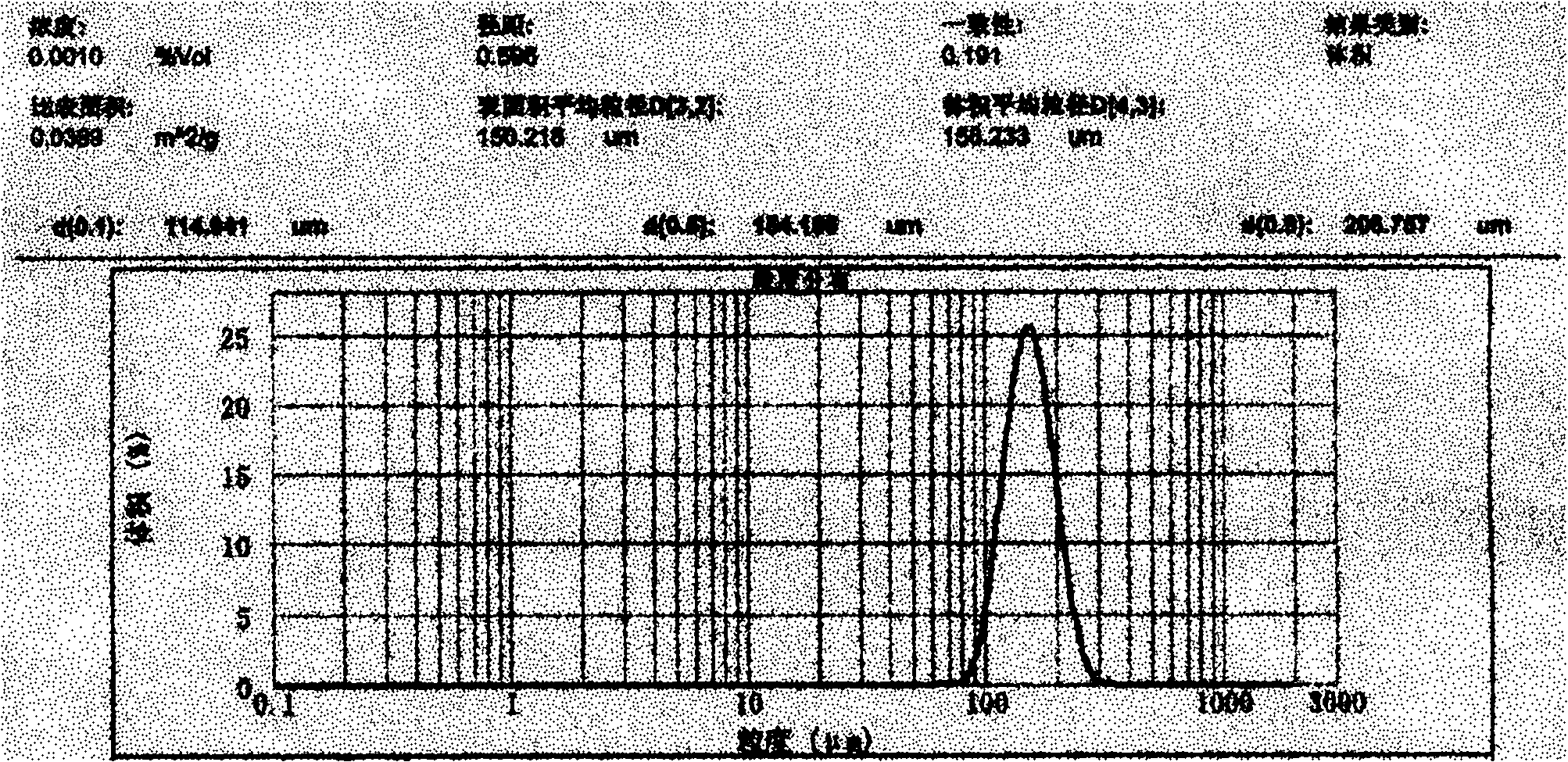

[0023] The preparation of embodiment 1 chitosan skeleton

[0024] 3.0 g of chitosan (molecular weight 30000 Da, deacetylation degree ≥ 95%) was dissolved in 100 mL of acetic acid solution with a mass fraction of 2.0%, and left standing overnight at room temperature for later use. In a 500mL three-necked bottle equipped with a mechanical stirrer and a thermometer, add 100mL of liquid paraffin, 15mL of cyclohexane, and 6 drops of Span 80 in sequence, and after stirring for 0.5h, add the above chitosan solution, and heat the system to 55°C with a water bath. ℃, stirred for 1 h, added 3 mL of glutaraldehyde with a mass fraction of 25%; adjusted the pH value to 10 with 10% NaOH solution, then raised the temperature to 65 °C, continued the reaction for 3 h, and filtered the micro The ball is filtered out, washed repeatedly with distilled water, then washed with petroleum ether and absolute ethanol, and vacuum-dried to constant weight to obtain a chitosan skeleton, 90% of which have ...

Embodiment 2

[0025] Embodiment 2 chitosan grafting

[0026] Take by weighing the product that 0.5g embodiment 1 obtains, after water fully swells, wash with the DMSO aqueous solution of 20%, 50%, 70% successively; Add 27mL DMSO / NaOH solution (DMSO volume fraction is 0.4 , the concentration of NaOH aqueous solution is 0.4mol / L) and epichlorohydrin, so that the volume fraction of epichlorohydrin is 10%, the shaking reaction is 4h, and the reaction temperature is 50°C. After the reaction, rinse with a large amount of distilled water until no epoxy group is detected in the cleaning solution. Chitosan epoxy group modification density was measured by sodium thiosulfate titration method, and the epoxy group modification density reached 0.1mmol / g.

Embodiment 3

[0027] Embodiment 3 chitosan grafting

[0028] Take by weighing the product that 0.5g embodiment 1 obtains, after water fully swells, wash with the DMSO aqueous solution of 20%, 50%, 70% successively; Add 27mL DMSO / NaOH solution (DMSO volume fraction is 0.5 , the concentration of NaOH aqueous solution is 0.4mol / L) and epichlorohydrin, so that the volume fraction of epichlorohydrin is 6%, the shaking reaction is 3h, and the reaction temperature is 40°C. After the reaction, rinse with a large amount of distilled water until no epoxy group is detected in the cleaning solution. Chitosan epoxy-modified density was measured by sodium thiosulfate titration method, and the epoxy-modified density reached 0.089mmol / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com