Pulsed gas jet impact drier

A technology of gas jet and drying machine, which is applied in application, food processing, food science, etc., can solve the problems of gas jet impact oven and gas jet impact drum, etc., and achieve stable operation, high hygienic index, and good consumption potential Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

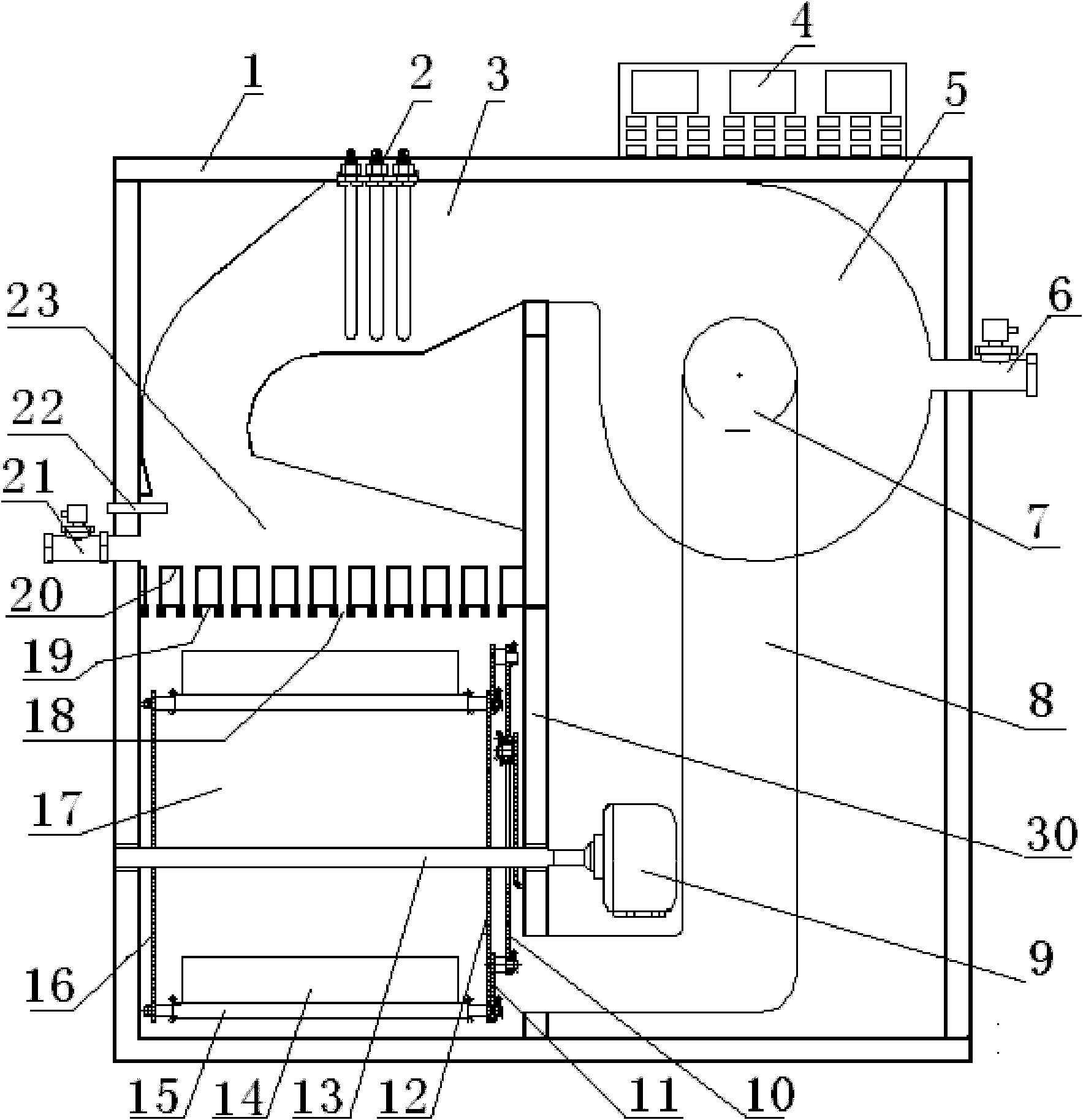

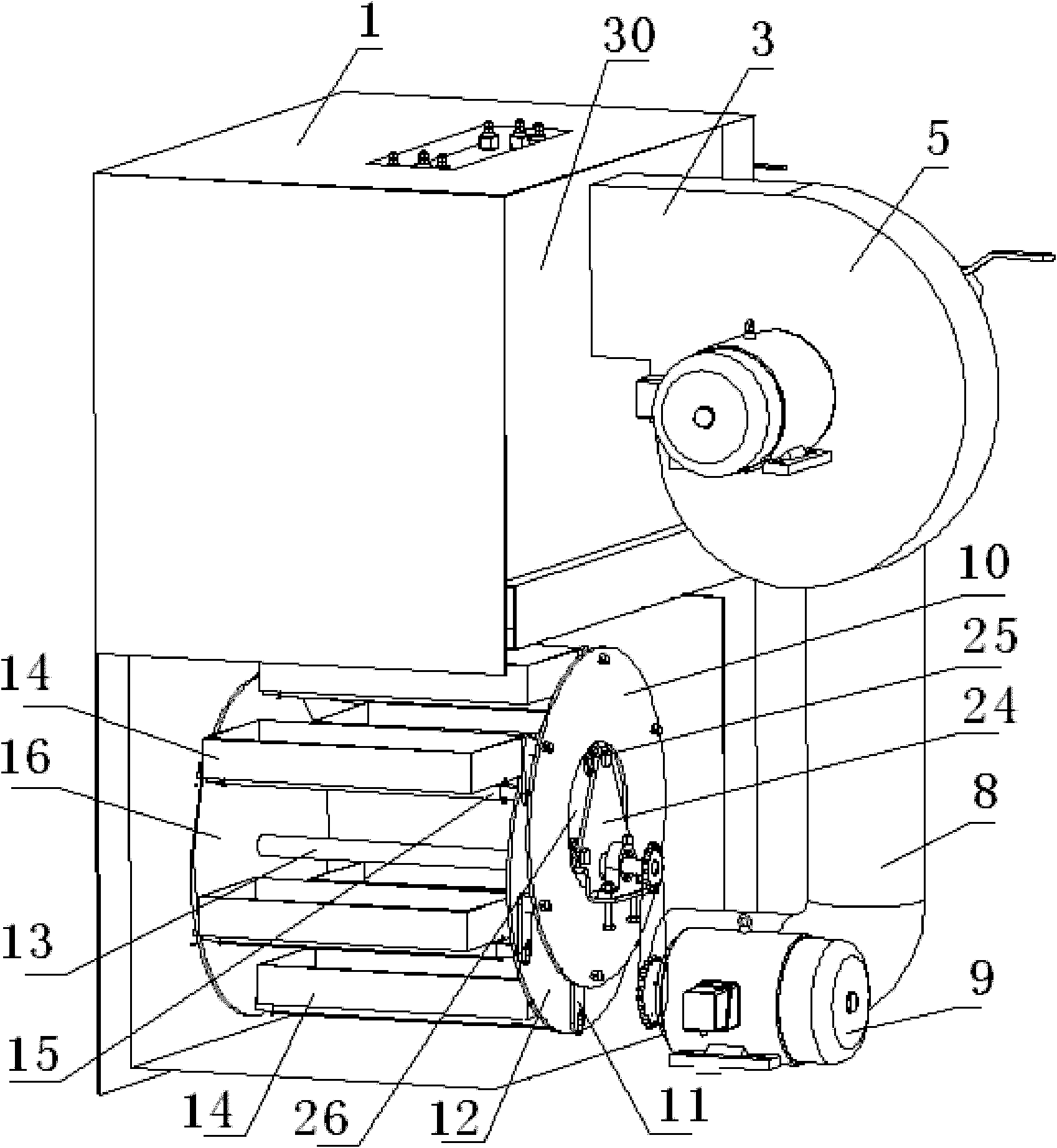

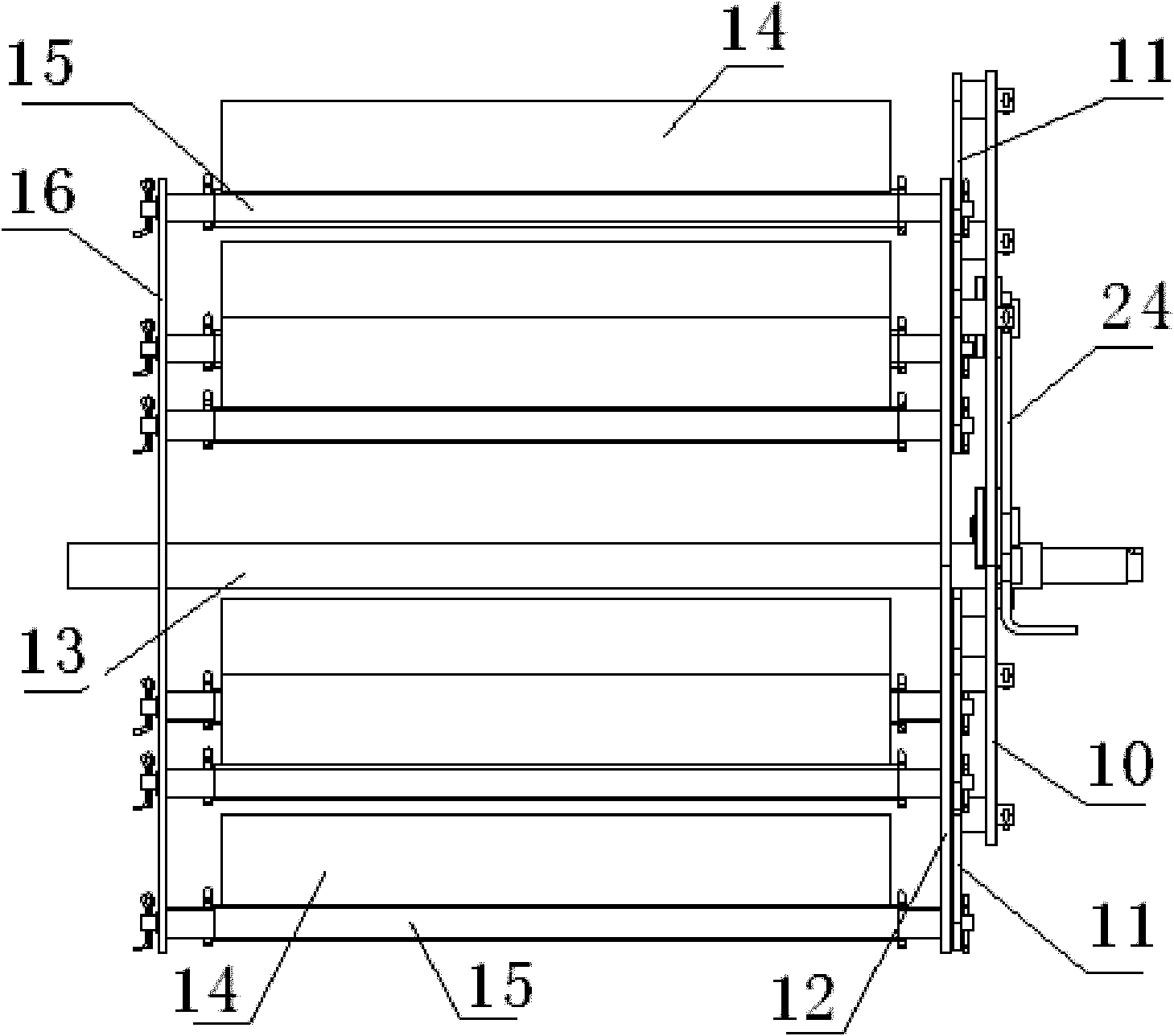

[0025] figure 1 with figure 2 It is a structural schematic diagram of an embodiment of a pulsating gas jet impingement dryer. The pulsating gas jet impingement dryer is composed of an air circulation system, a material drying system, a temperature and humidity control system and a chassis. The middle partition 30 in the cabinet 1 divides the inside of the cabinet into two parts, the left and the right, and the air circulation system includes the blower fan 5, the blower blower outlet duct 3, the airflow heating device 2, the airflow distribution chamber 23, the return air duct 8 and the jet plate. The fan 5 is placed on the upper part of the cabinet 1 on the right side of the middle partition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com