MEMS microphone package and packaging method

A technology of microelectronic machinery and microphones, which is applied in the direction of electrostatic transducer microphones, microelectronic microstructure devices, microphones, etc., can solve the problems of reduced sensitivity, small capacitance, and degradation of low-frequency band characteristics, and achieve the prevention of sensitivity , maintain balance, improve the effect of sound characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention and the technical subject achieved by carrying out the present invention will be further clarified by preferred embodiments of the present invention described below. The following examples are merely examples for illustrating the present invention and do not limit the scope of the present invention.

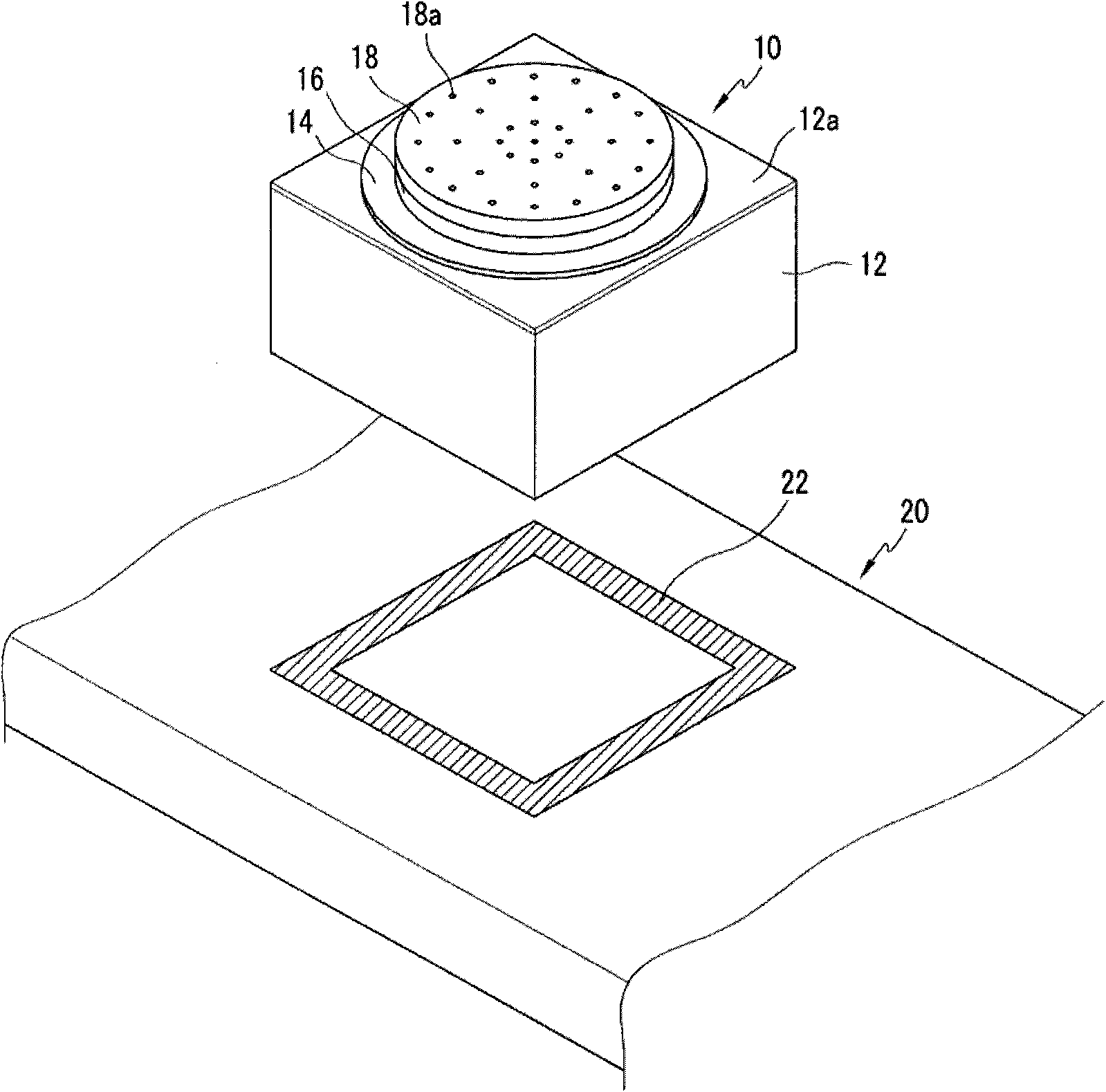

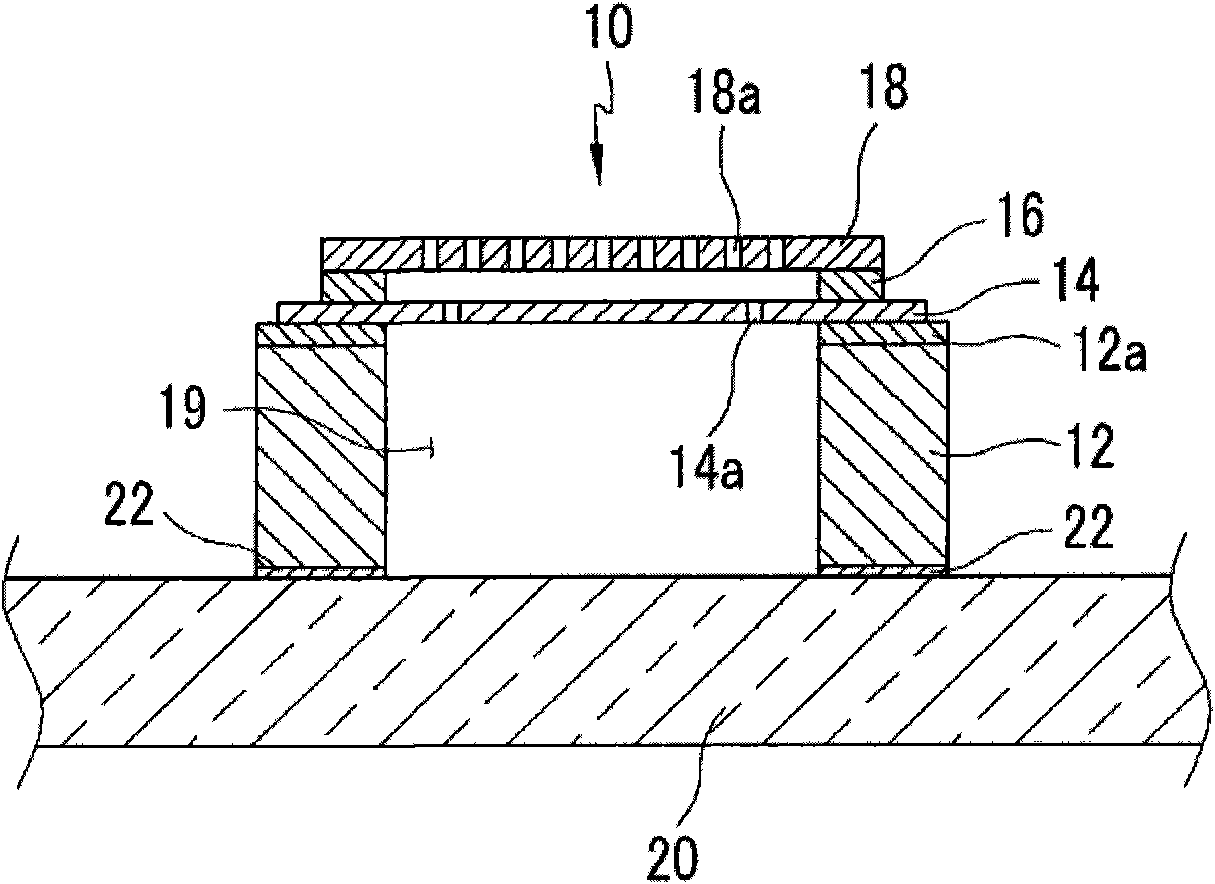

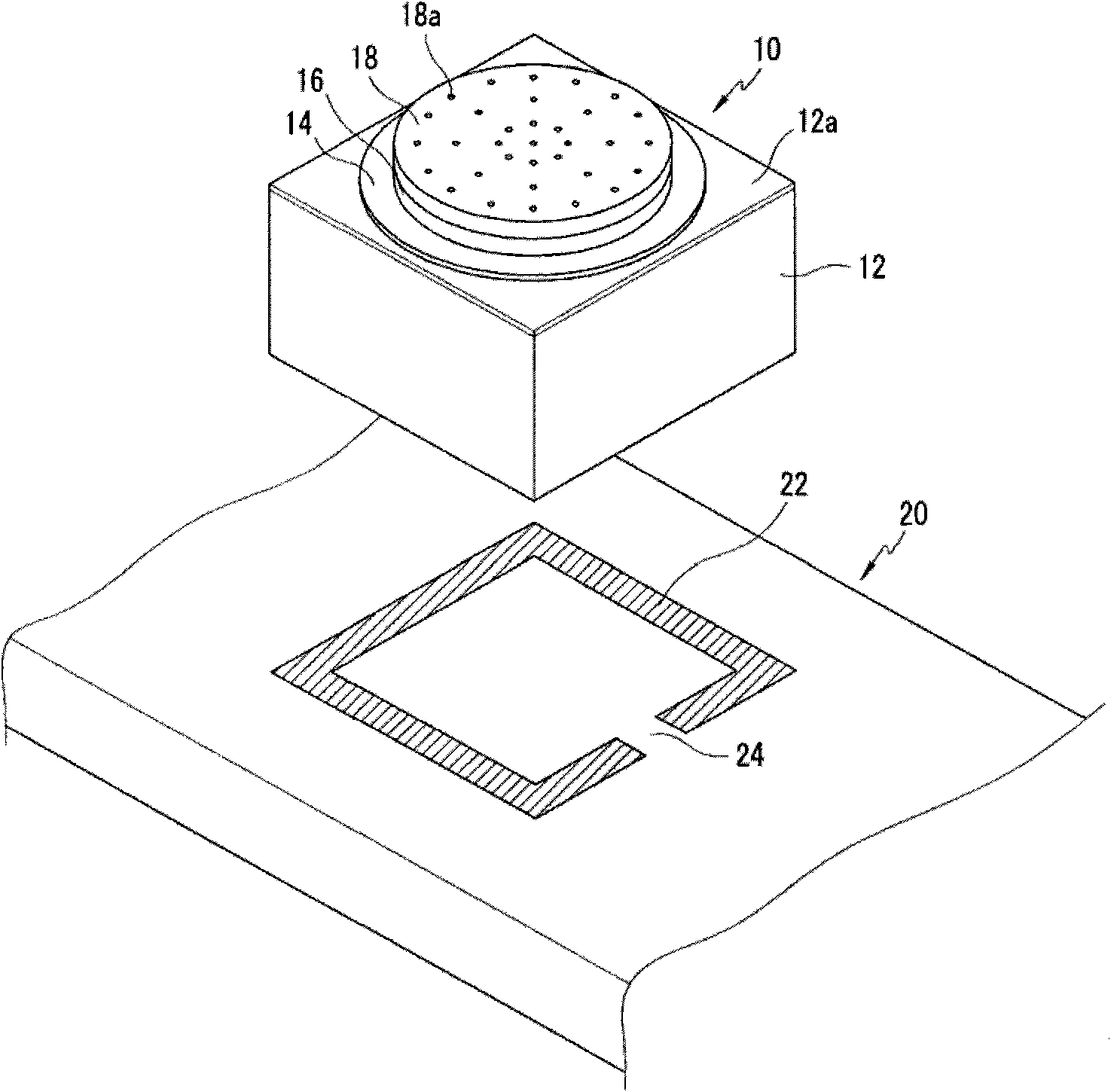

[0026] image 3 It is a schematic diagram showing an example in which a microelectromechanical system microphone chip is attached to a substrate in the present invention, Figure 4 It is a side sectional view of an example in which a microelectromechanical system microphone chip is pasted on a substrate in the present invention.

[0027] Such as image 3 Figure 4 As shown, the MEMS microphone assembly of the present invention uses a silicon substrate to form a MEMS microphone chip 10 having a support plate and a vibrating film, and then pastes it on the PCB substrate 20 with an adhesive 22 for assembly, but a part of the vacant sticking part is ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com