Optical module and manufacturing method thereof

A manufacturing method and optical module technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as chip function failure and packaging failure, achieve high-temperature aging without failure, reduce the probability of failure, and produce finished products rate-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

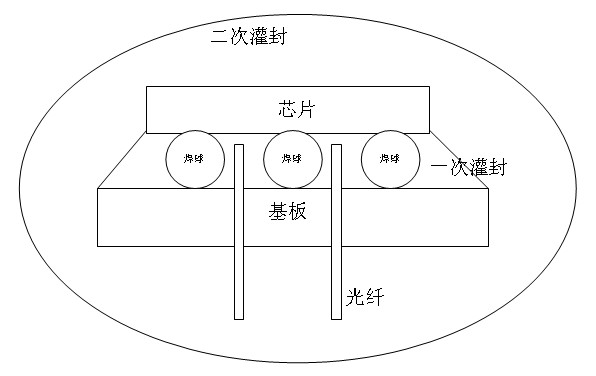

[0014] A package structure of an optical module disclosed in the present invention is attached figure 1 . The optical module includes a substrate and a chip that is flip-chip-bonded with the substrate. The space between the substrate and the chip is potted with transparent silicone, and the outside of the substrate and the chip is potted with potting glue.

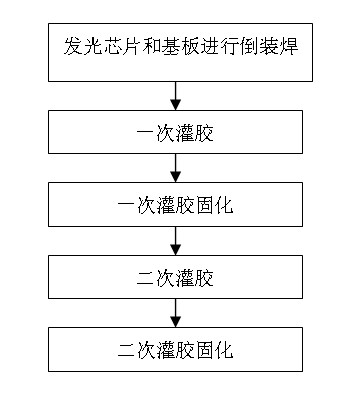

[0015] In potting, EXF1000 glue dispenser can be used, and the thickness of the glue is about 20-25 microns. Transparent silica gel is used for the first potting, and its model is preferably OE6551 silica gel, and its CTE is 210±100ppm / °C. After dispensing, heat the optical module in an oven, preferably to 90±5°C, and continue heating for 240 minutes, then cool natu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com