Probe protecting dynamic balance mechanism of high-temperature industrial television in small heating furnace

A high-temperature industry and heating furnace technology, applied in the field of small heating furnace high-temperature industrial TV probe protection dynamic balance mechanism, can solve the problems of motor overload transmission mechanism paralysis, transmission blockage, burning, etc., achieve reciprocating smooth operation, accurate positioning, and overcome thermal deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

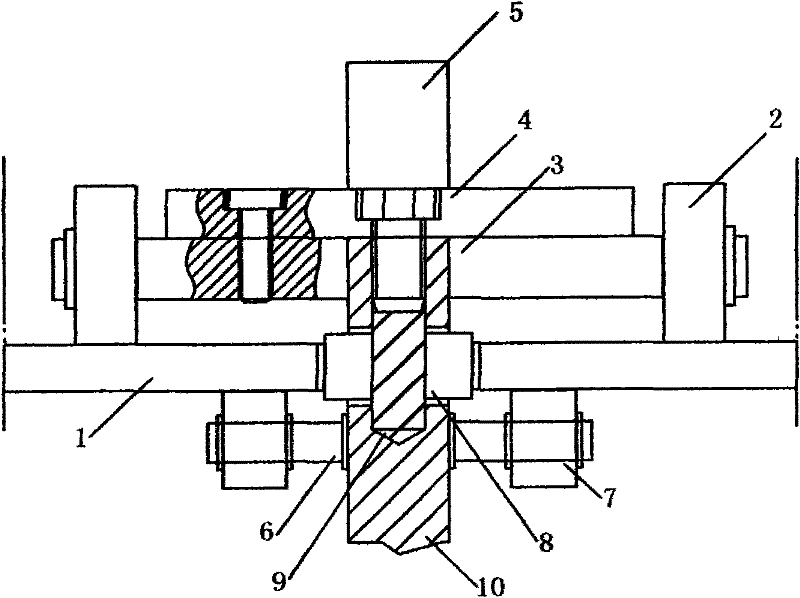

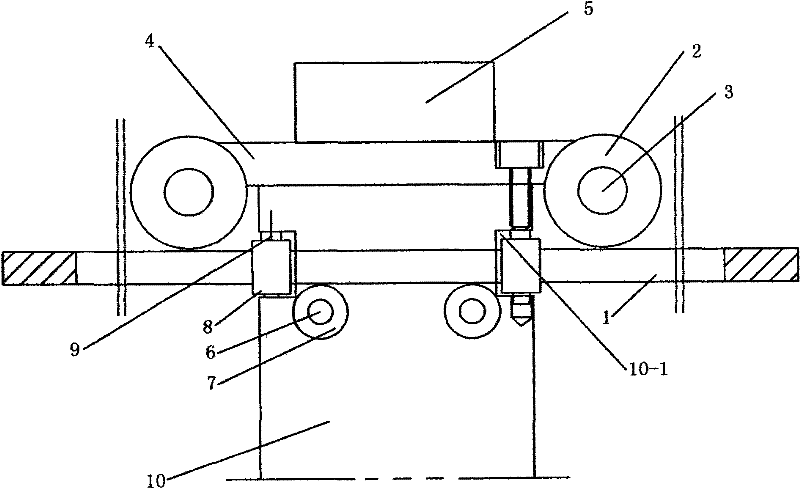

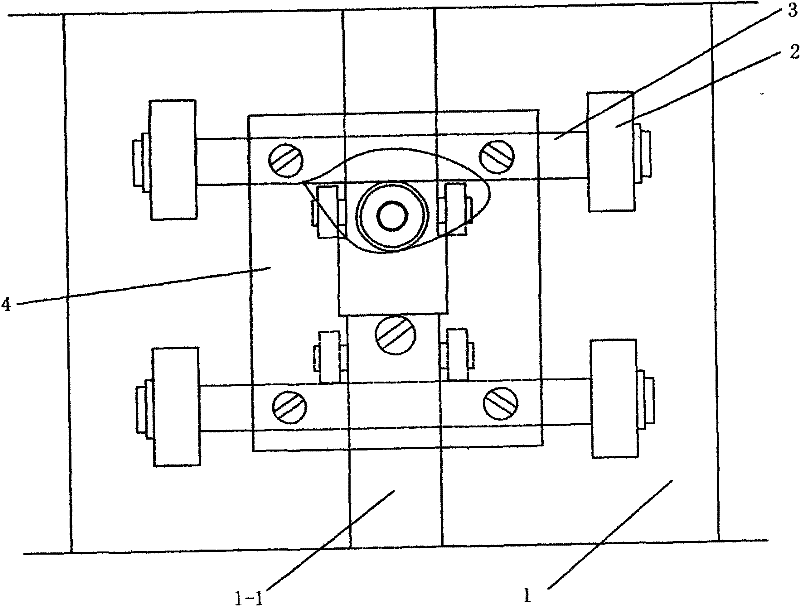

[0010] like Figure 1~3 As shown, the small heating furnace high temperature industrial TV probe protects the dynamic balance mechanism, including base 1, bearing wheel 2, bearing wheel shaft 3, sports main board 4, adapter 5, auxiliary driving wheel shaft 6, auxiliary driving wheel 7, and centering wheel 8 , the centering wheel shaft 9 and the vertical plate 10 of the moving body. The base 1 is rectangular, and a rectangular through slot 1-1 is provided along the center line of the rectangular plate; the vertical plate 10 of the moving body is rectangular, and two auxiliary drive shafts 6 are fixed on the surface of the rectangular plate, and each auxiliary drive shaft 6 is Two auxiliary driving wheels 7 are installed, grooves 10-1 are arranged symmetrically on both sides of the rectangular plate; Axle 3, two load-bearing wheels 2 are installed on every load-bearing wheel axle 3.

[0011] Two auxiliary drive shafts 6 are respectively passed through the shaft holes provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com