Ecological slag permeable bricks and preparation method thereof

A kind of permeable brick, ecological technology, applied to the pavement, road, road and other directions paved with prefabricated blocks, it can solve the problems of high dust content in the air, loss of water permeability function, unfavorable ecological environment protection, etc., and achieve good water permeability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

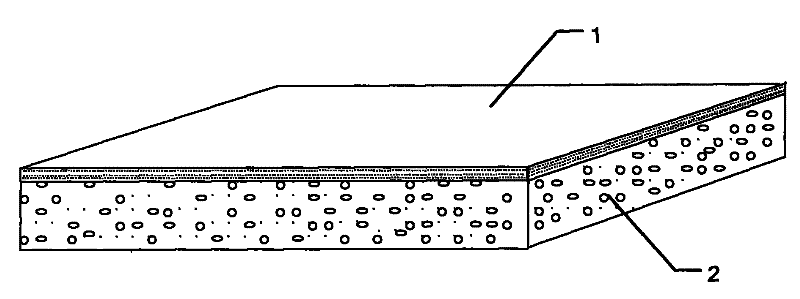

[0030] According to an embodiment of the present invention, an ecological slag permeable brick is provided. Such as figure 1 As shown, this embodiment includes a basic strength water-permeable layer 2 and a sensory water-permeable layer 1 bonded to the upper surface of the basic-strength water-permeable layer 2. Here, the sensory water-permeable layer 1 is formed by dividing cloth and vibration extrusion, and is bonded to the upper surface of the basic-strength water-permeable layer 2.

[0031] Further, in this embodiment, the material for preparing the above-mentioned basic strength water-permeable layer 2 includes the following components and raw materials in parts by weight:

[0032] Ecological residue: 70 copies;

[0033] Cement: 20 parts;

[0034] Silica fume: 3 parts;

[0035] Melamine: 3 parts;

[0036] Water: 5.6 parts.

[0037] Wherein, in the above embodiment, the ecological slag has a plurality of spherical closed-hole particles, and during the grading, the contact points bet...

Embodiment 2

[0047] Different from the above-mentioned embodiment, in this embodiment, the preparation material of the basic strength water-permeable layer 2 includes the following components and parts by weight of raw materials:

[0048] Ecological residue: 80 parts;

[0049] Cement: 16 parts;

[0050] Silica fume: 2 parts;

[0051] Melamine: 1 part;

[0052] Water: 8.0 parts.

[0053] Further, in this embodiment, the preparation material of the sensory water-permeable layer 1 includes the following components and raw materials in parts by weight:

[0054] Cement: 19.5 parts;

[0055] Quartz sand: 70 parts;

[0056] Pigment: 3.5 parts;

[0057] Water-based resin: 4.5 parts;

[0058] Water: 5 parts.

[0059] Further, in the above-mentioned ecological residue, the content of acicular particles in parts by weight is 5%, the weight ratio of round particles to flaky particles is 5:1, and the content of powder in parts by weight is 10%; the aggregate size The configuration is 8mm, and the volume density is 3.5...

Embodiment 3

[0061] Different from the above-mentioned embodiment, in this embodiment, the preparation material of the basic strength water-permeable layer 2 includes the following components and parts by weight of raw materials:

[0062] Ecological residue: 75 copies;

[0063] Cement: 18 parts;

[0064] Silica fume: 5 parts;

[0065] Melamine: 2 parts;

[0066] Water: 6.975 parts.

[0067] Further, in this embodiment, the preparation material of the sensory water-permeable layer 1 includes the following components and raw materials in parts by weight:

[0068] Cement: 22 parts;

[0069] Quartz sand: 65 parts;

[0070] Pigment: 4 parts;

[0071] Water-based resin: 7 parts;

[0072] Water: 6.6 parts.

[0073] Further, in the above-mentioned ecological residue, the content of the needle-shaped particles in parts by weight is 3%, the weight ratio of the round particles to the flaky particles is 9:5, and the content in parts by weight of the powder is 2%; the particle size of the aggregate The configuration i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com