Polarizing machine

A kind of shaker and chassis technology, which is applied in the direction of heating/cooling fabric, textile and paper making, roughening, etc., to achieve the effect of full surface and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

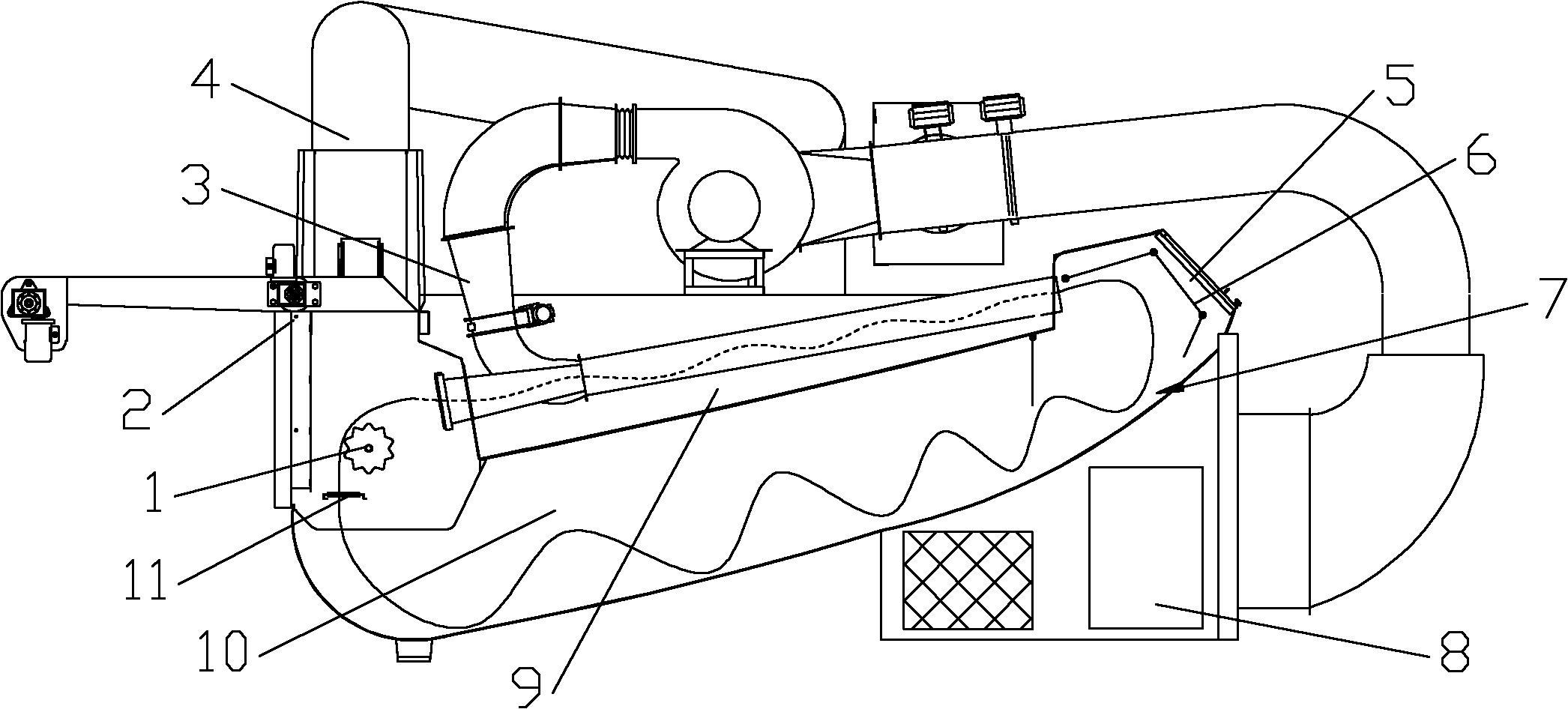

[0021] Attached below figure 1 and 2 The preferred embodiments of the present invention are described in detail, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0022] A kind of shaker, comprising a frame and a cabinet 10 arranged on the frame, the inside of the cabinet 10 includes a Venturi tube 9, a cloth guide device 1 positioned at the front end of the Venturi tube 9 and an impactor positioned at the rear end of the Venturi tube 9. The grid plate 6, the Venturi tube 9 communicates with the air inlet pipe 3 passing through the cabinet 10, and it is characterized in that: the cabinet 10 includes a high temperature box 12, an incubator 13 communicated with the high temperature box 12 and an incubator The cooling box 14 connected to the box 13, the air inlet duct 3 includes a high-temperature air duct 17 communicating with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com