External thermal insulation structure of electrolytic cell

A technology of external heat preservation and electrolytic cell, which is applied in the field of aluminum electrolytic cell, can solve the problems that the inner lining structure is not feasible, and achieve the effects of cost and time saving, easy adjustment, and convenient insulation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

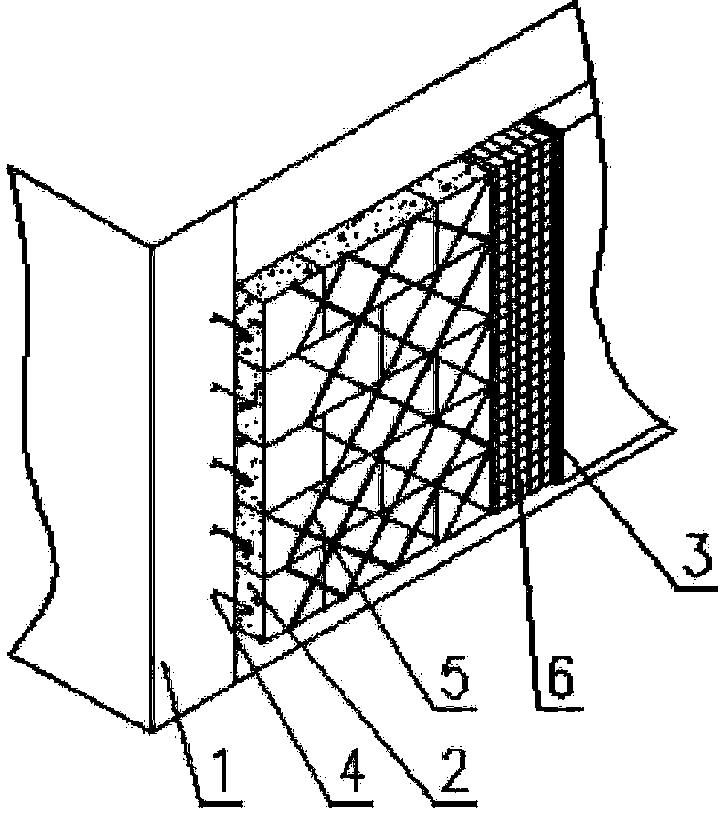

[0017] Embodiment 1: as figure 2 As shown, the insulation layer 2 is laid outside the electrolytic cell shell 1, and the insulation layer 2 can adopt a plate-like hard and semi-hard insulation material layer, such as a hydrophobic expanded perlite insulation layer, insulation cotton board, etc. When the thermal insulation material layer is used as the thermal insulation layer, an expansion joint is left between two hard thermal insulation material layers, and a flexible thermal insulation material layer is filled in the expansion joint. After the insulation layer 2 is placed, the insulation layer 2 is fixed by the hook nails 4 of the fixing parts welded on the electrolytic cell shell 1. The outside of the insulation layer 2 is fastened with galvanized iron wire 5 and galvanized wire mesh 6 and the hook nails 4. Adopt plastering structure to make protective layer 3 on 6, also can not make protective layer 3.

Embodiment 2

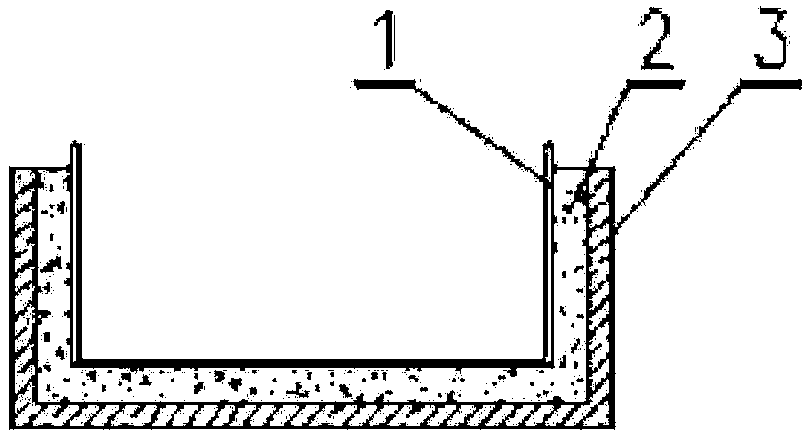

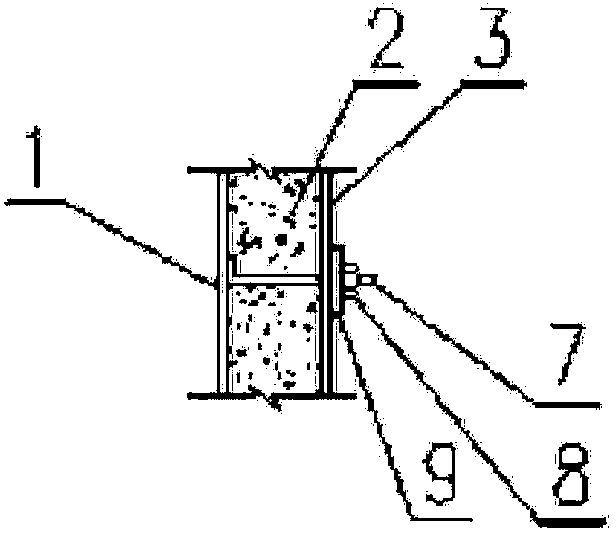

[0018] Embodiment 2: as figure 1 with image 3 As shown, an insulation layer 2 is laid outside the electrolytic cell shell 1. The insulation layer 2 can be made of composite silicate felt, microporous calcium silicate products, rock wool and slag wool felt, board products, ultra-fine glass wool products, poly Polyurethane foam plastics, hydrophobic expanded perlite products, cement expanded perlite products, aluminum silicate products, foam glass, etc., the insulation layer 2 can be one layer, two layers or more than two layers, each layer can use the same or Different insulation materials, the protective layer 3 laid outside the thermal insulation layer 2 can be a metal or aluminum foil glass fiber reinforced plastic sheet, the thermal insulation layer 2 and the protective layer 3 are connected by the fixing piece pin 7 welded on the electrolytic cell shell 1, and the nut 8 and the gasket 9 fixed.

Embodiment 3

[0019] Embodiment 3: as figure 1 with Figure 4 As shown, a thermal insulation device is laid outside the electrolytic cell shell 1. The thermal insulation device includes a thermal insulation layer 2 and a protective layer 3. The area covered by the thermal insulation device on the electrolytic cell shell 1 is 1% to 100%, and the protective layer 3 is a composite The protective layer, the metal protective layer or the aluminum foil glass fiber reinforced plastic sheet, is connected and fixed by the fixing member pin 10 welded on the electrolytic cell shell 1 and the self-locking plate 11 to fix the insulating layer 2 and the protective layer 3 . A supporting member can be erected on the electrolyzer shell 1 to support the insulation layer 2 .

[0020] The protective layer 3 can be a metal protective layer, a composite protective layer or a plastering protective layer: the metal protective layer can be galvanized thin steel plate, galvanized iron sheet, aluminum alloy plate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com