Method for recycling DL-lysine hydrochloride from aspirin-DL-lysine mother liquor

A technology of lysine hydrochloride and lysine-pirin, which is applied in the field of recovery of DL-lysine hydrochloride from lysine-pirin mother liquor, can solve the problems of difficulty, difficult waste liquid treatment, waste, etc. Achieve the effect of avoiding waste, saving energy and cost, high economic benefit and social benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

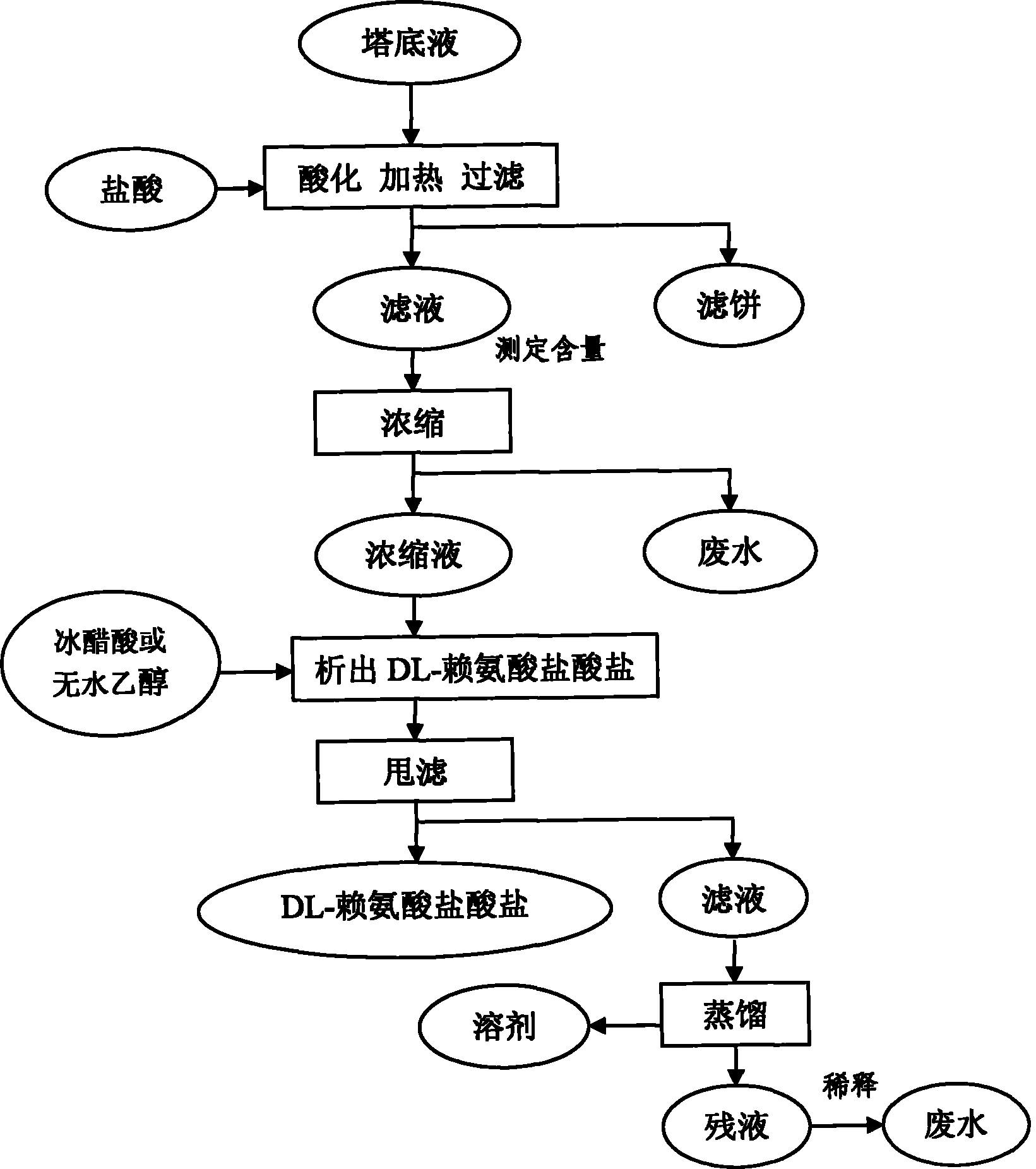

Image

Examples

Embodiment 1

[0030] (1) Acid separation and precipitation

[0031] Take the lysine-pirin mother liquor, recover ethanol with a distillation tower, take 1000ml of the bottom liquid, stir, add 30ml of hydrochloric acid, adjust the pH to 3, heat to 90°C, keep for 30 minutes, cool to 20°C, filter to obtain the filtrate.

[0032] (2) concentrated

[0033] The filtrate was put into a still, and concentrated in vacuum at 70°C until the concentration of DL-lysine hydrochloride was 60%.

[0034] (3) Precipitation

[0035] Measure the concentrated solution, add 1 times the amount of glacial acetic acid dropwise, slowly cool down to 10°C, keep warm for 3 hours, shake off, wash once with a small amount of glacial acetic acid or absolute ethanol to obtain DL-lysine hydrochloride.

[0036] (4) Content determination

[0037] Using the perchloric acid method, the content of DL-lysine hydrochloride was measured to be 97.5%.

[0038] The COD value of the lysine-pirin mother liquor after treatment is 66,...

Embodiment 2

[0040] (1) Acid separation and precipitation

[0041] Take the lysine-pirin mother liquor, recover ethanol with a distillation tower, take 1000ml of the bottom liquid, stir, add 50ml of hydrochloric acid, adjust the pH to 2, heat to 80°C, keep for 25 minutes, cool to 18°C, filter to obtain the filtrate.

[0042] (2) concentrated

[0043] The filtrate was put into a distillation pot and concentrated in vacuum at 75°C until the concentration of DL-lysine hydrochloride was 65%.

[0044] (3) Precipitation

[0045] Measure the concentrated solution, add 1.5 times the amount of glacial acetic acid dropwise, slowly cool down to 8°C, keep warm for 3 hours, shake off, wash once with a small amount of glacial acetic acid or absolute ethanol to obtain DL-lysine hydrochloride.

[0046] (4) Content determination

[0047] Using the perchloric acid method, the content of DL-lysine hydrochloride was measured to be 99.1%.

[0048] The COD value of the lysine-pirin mother liquor after treat...

Embodiment 3

[0050] (1) Acid separation and precipitation

[0051] Take the lysine-pirin mother liquor, recover ethanol with a distillation tower, take 1000ml of the bottom liquid, stir, add 70ml of hydrochloric acid, adjust the pH to 1.5, heat to 80°C, keep for 20 minutes, cool to 15°C, filter to obtain the filtrate.

[0052] (2) concentrated

[0053] The filtrate was put into a still, and concentrated in vacuum at 80°C until the concentration of DL-lysine hydrochloride was 70%.

[0054] (3) Precipitation

[0055] Measure the concentrated solution, add 1 times the amount of absolute ethanol dropwise, slowly cool down to 5°C, keep warm for 4 hours, shake off, wash once with an appropriate amount of glacial acetic acid or absolute ethanol to obtain DL-lysine hydrochloride.

[0056] (4) Content determination

[0057] Using the perchloric acid method, the content of DL-lysine hydrochloride was measured to be 98.6%.

[0058] The COD value of the lysine-pirin mother liquor after treatment is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com