Ultrasonic printing and trimming device

An ultrasonic and edge-cutting technology, applied in decorative arts, textiles and papermaking, embossed decorative parts, etc., can solve the problems of inability to truly and comprehensively reflect the working state of ultrasonic printing and cutting, high cost, low production efficiency, etc. The effect of reducing equipment cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

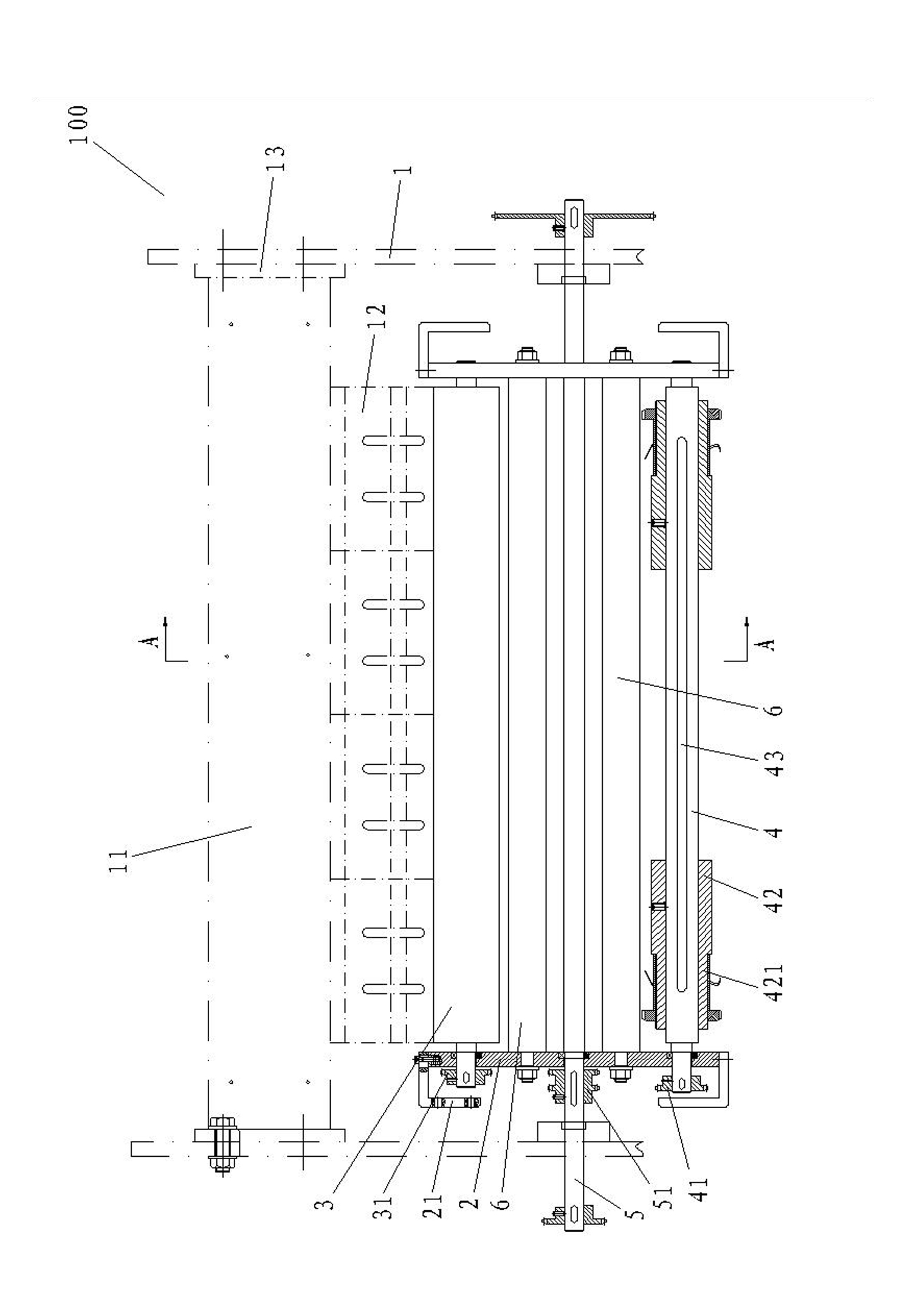

[0043] Such as figure 1 As shown, it shows an ultrasonic printing and edge trimming device 100 related to the present invention, including a support mechanism 1, a support plate 2, a printing roller 3, an edge trimming roller 4, and a drive shaft 5, wherein:

[0044] The support mechanism 1, as the carrying body of the ultrasonic printing and trimming device 100 of the present invention, has a main support 11, and the main support 11 is provided with an ultrasonic generator 12, and the ultrasonic generator 12 can be specifically arranged in multiples, When in use, select to open corresponding number of ultrasonic generators 12 according to the width of the cloth, specifically the two ends of the main support 11 are also locked on the support mechanism 1 through the flange 13; the main support 11 is preferably a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com