Sleeving device for elastic ring parts

A technology of elastic rings and sets, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low installation efficiency, damage to ring parts, time-consuming and labor-intensive installation, etc., to ensure assembly quality, save space, and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following is a detailed description of the embodiments of the present invention. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

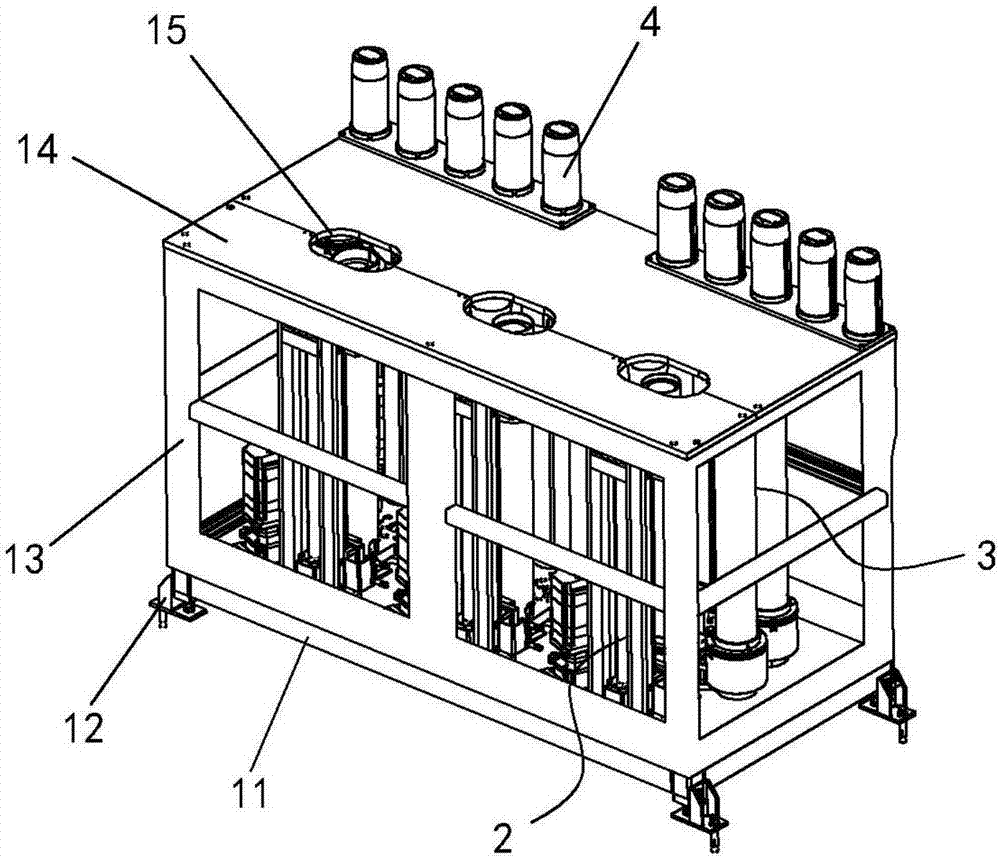

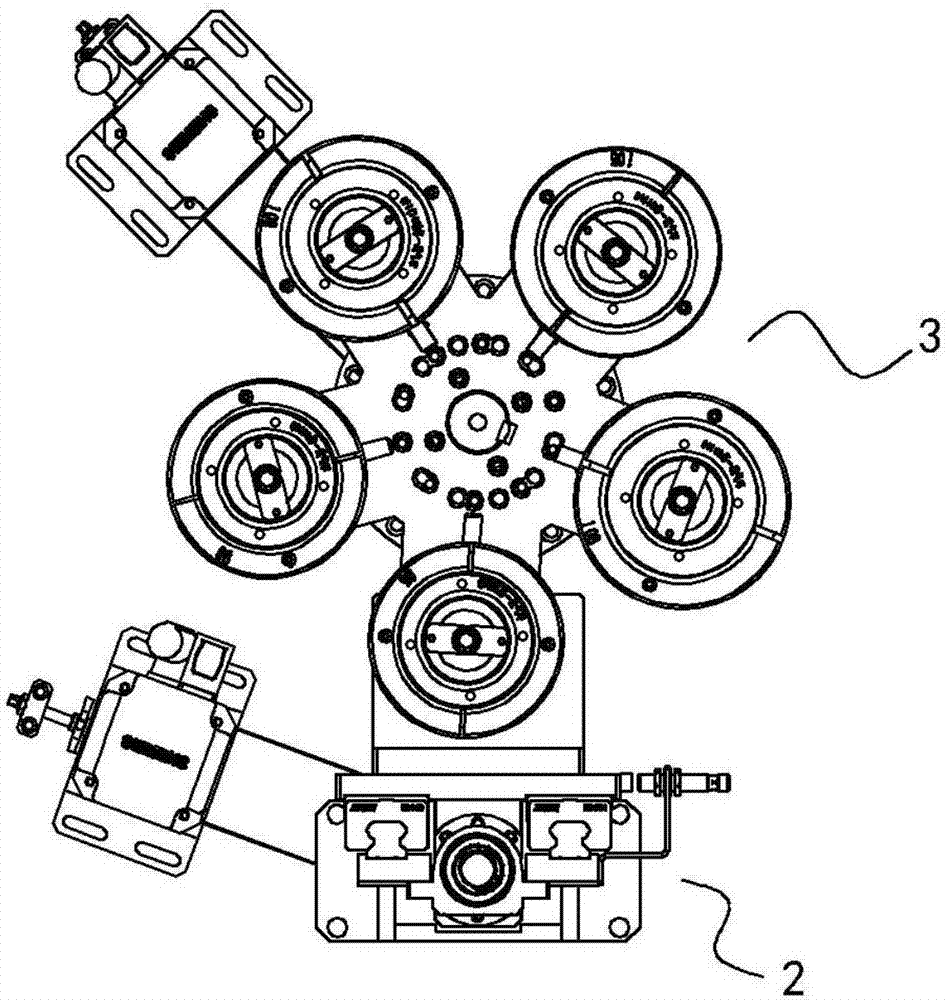

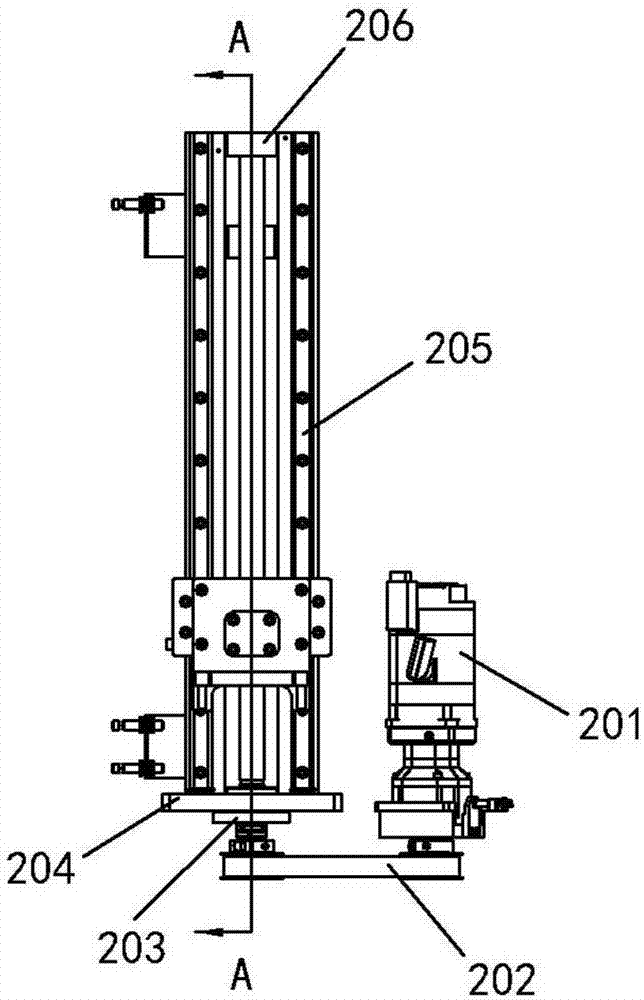

[0031] Such as Figure 1 to Figure 7 As shown, its structural relationship is as follows: it includes a frame 1 for supporting and connecting, a working plane 14 is fixed on the bottom plate 11 through a frame 13 to form a frame 1, and a set hole 15 is set on the working plane 14, and it also includes an elastic ring for executing The set-up mechanism 2 and the index plate mechanism 3 for feeding materials, the index plate mechanism 3 includes the index plate power mechanism for driving, the index turntable 305 for supporting and fixing, and the cross roller bearing 304 and act on the elastic ring typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com