Feeding and discharging device of semiconductor packaging material box

A packaging material and semiconductor technology, used in semiconductor/solid-state device manufacturing, transportation and packaging, lighting and heating equipment, etc., can solve problems such as complex structure, substrate scratches, pressure injuries, etc., to achieve simple and reliable mechanism and reduce production. Cost, loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

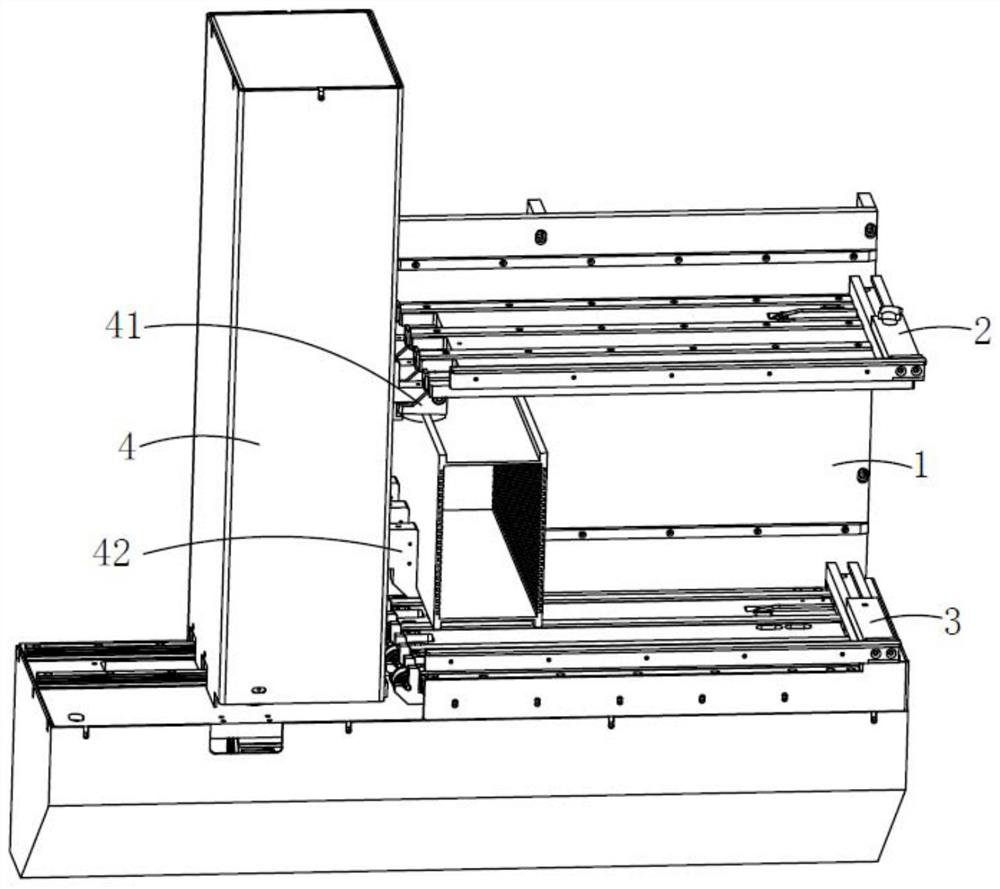

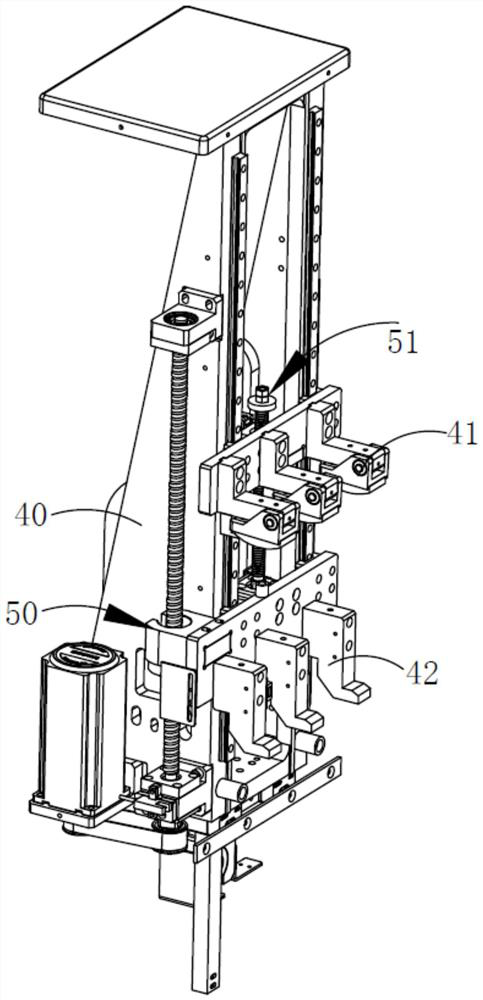

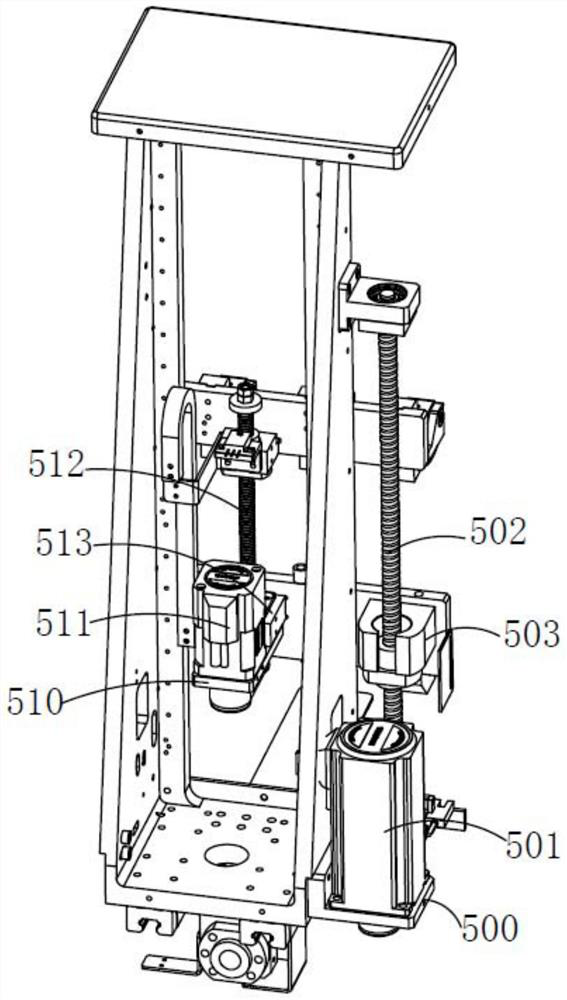

[0024] Such as Figures 1 to 4 As shown, the present invention provides a loading and unloading device for semiconductor packaging magazines, which includes a stand 1, an upper support structure 2 arranged on the top of the stand 1, a lower support structure 3 arranged at the bottom of the stand 1, and a feeding Lifting device 4, feeding lifting device 4 is provided with Z-axis seat 40, lifting drive mechanism, the material box upper clip 41 that is slidably arranged on Z-axis seat 40 tops and the material box lower clip 42 that is slidably arranged on Z-axis seat 40 bottom, material The box upper clamp 41 and the material box lower clamp 42 are arranged up and down to clamp the material box, and the lifting drive mechanism is used to drive the material box upper clamp 41 and the material box lower clamp 42 to lift synchronou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com