Ti target material and Al backboard welding method

A welding method and technology of the back plate, applied in the direction of welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems that heavy pressure cannot be applied, diffusion welding method cannot be used, and it is easy to break apart, so as to achieve the effect of improving the bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

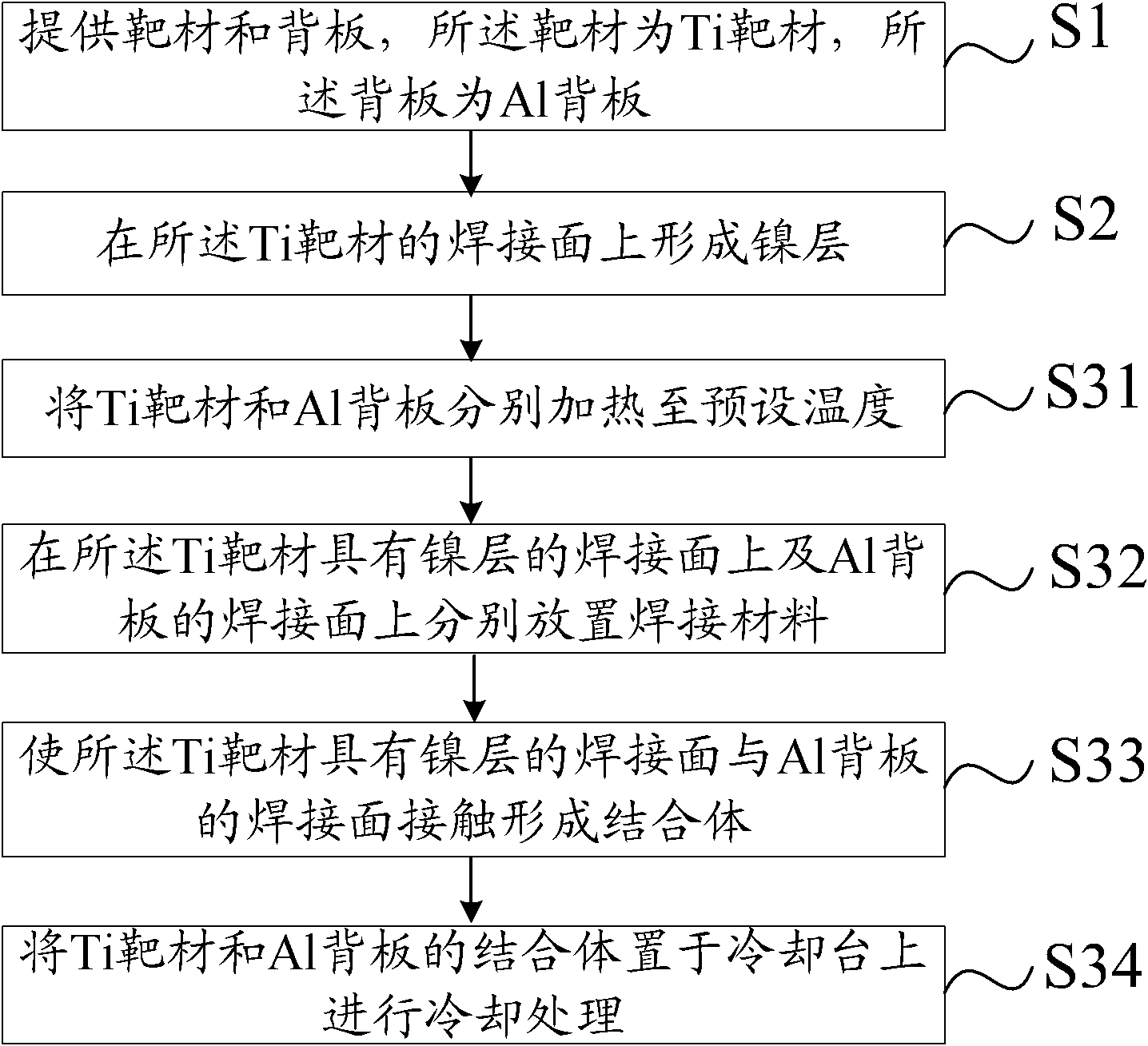

[0034] refer to figure 1 , figure 1 It is a schematic flowchart of a welding method for a titanium target aluminum back plate provided by an embodiment of the present invention. The method specifically includes:

[0035] Step S1: providing a target material and a back plate, the target material is a Ti target material, and the back plate is an Al back plate.

[0036] In the embodiment of the present invention, the target material is a Ti target material, and the back plate is an Al back plate. The shape of the target can be determined according to specific needs, for example, the surface of the target can be set to be triangular, rectangular or circular.

[0037] Step S2: forming a nickel layer on the welding surface of the Ti target.

[0038] Since the thermal expansion coefficients of Ti and Al are quite different (the thermal expansion coefficient of Ti is 10.8, and the thermal expansion coefficient of Al is 23.2), when the Ti target and the Al back plate are combined b...

Embodiment 2

[0043] The method for welding the titanium target aluminum back plate provided by the present invention will be described in detail below with a specific embodiment. refer to figure 2 , figure 2 It is a schematic flow chart of another method for welding a titanium target aluminum back plate provided by the embodiment of the present invention, and the method is specifically as follows:

[0044] Step S1: providing a target material and a back plate, the target material is a Ti target material, and the back plate is an Al back plate.

[0045] refer to image 3 , the surface of the Ti target described in this embodiment is in the shape of a triangle, the bottom b of the triangle is 352.044 mm, the height a is 387.35 mm, the thickness of the Ti target is 10 mm, and a margin of 2 mm is added to the thickness of the 10 mm, The purpose of increasing the margin is to prevent the serious shrinkage of the Ti target during the cooling process and affect the subsequent processing step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com