Double-screw rod kneading device

A kneader and twin-screw technology, applied in mixers, mixers with rotary stirring devices, mixer accessories, etc., to achieve the effects of ensuring axial positioning, simple structure, and widening use conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

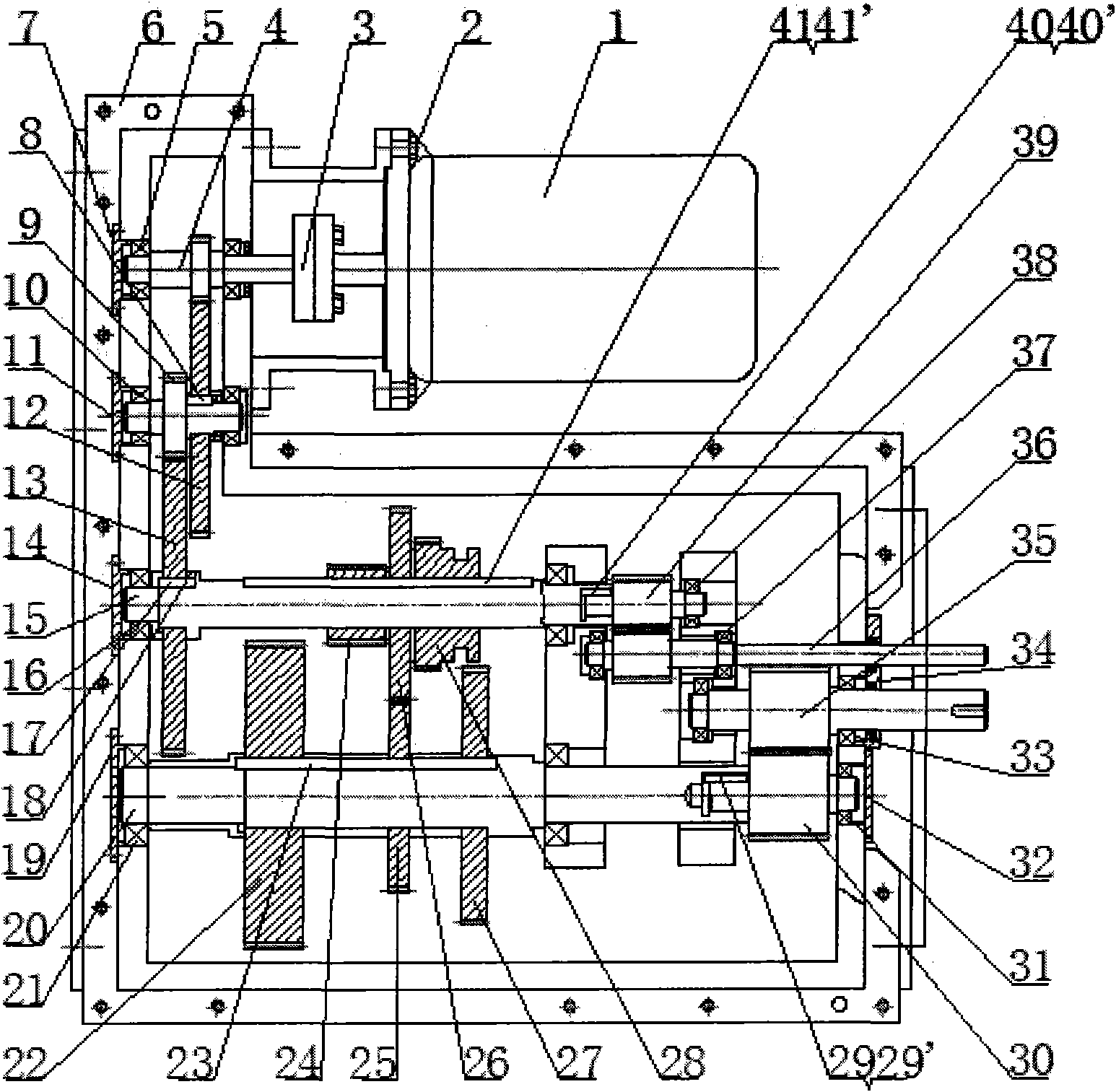

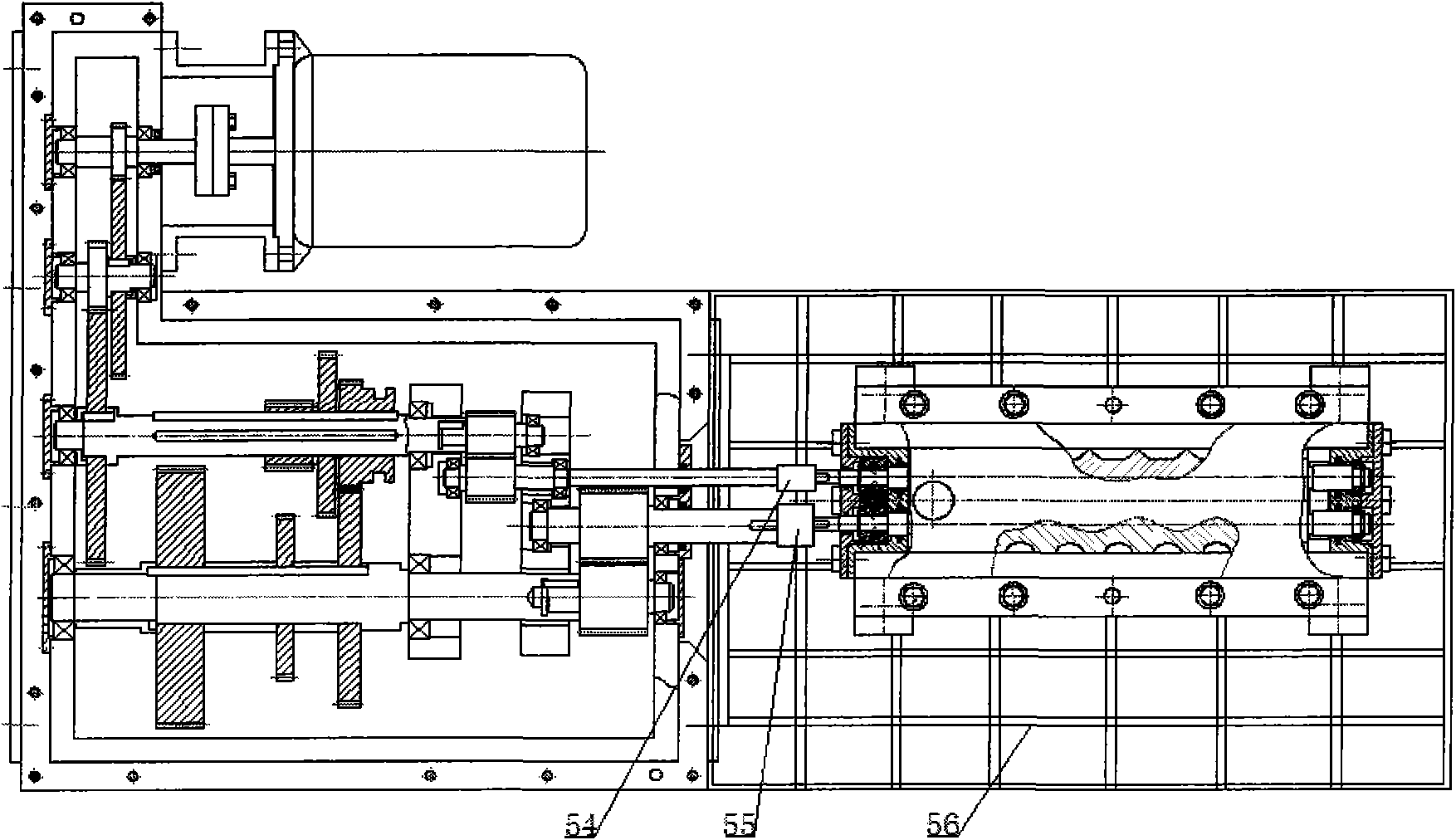

[0023] like figure 1 As shown, the motor 1 is connected with the first-stage gear shaft 4 of the gearbox input shaft through a coupling 3 to transmit the motive force, and the first-stage gear shaft 4 and the second-stage gear shaft 9 are meshed through the first-stage large gear 12, The second-stage gear shaft 9 and the sliding gear shaft 15 are meshed through the second-stage large gear 13; The sliding gear set can be adjusted so that the sliding gear set meshes with the mating gear on the power shaft 20 to transmit power. Adjust the 1:1 gear gear 26 in the sliding gear set to the position where it meshes with the 1:1 gear mating gear 25 through the shift lever, the specific position can be seen figure 1 The position of the slipping gear set. The sliding gear shaft 15 and the power shaft 20 are respectively connected to the other two transition shafts by splines—a high-speed transition shaft 39 and a low-speed transition shaft 30; The gears are meshed, and the power is tr...

Embodiment approach 2

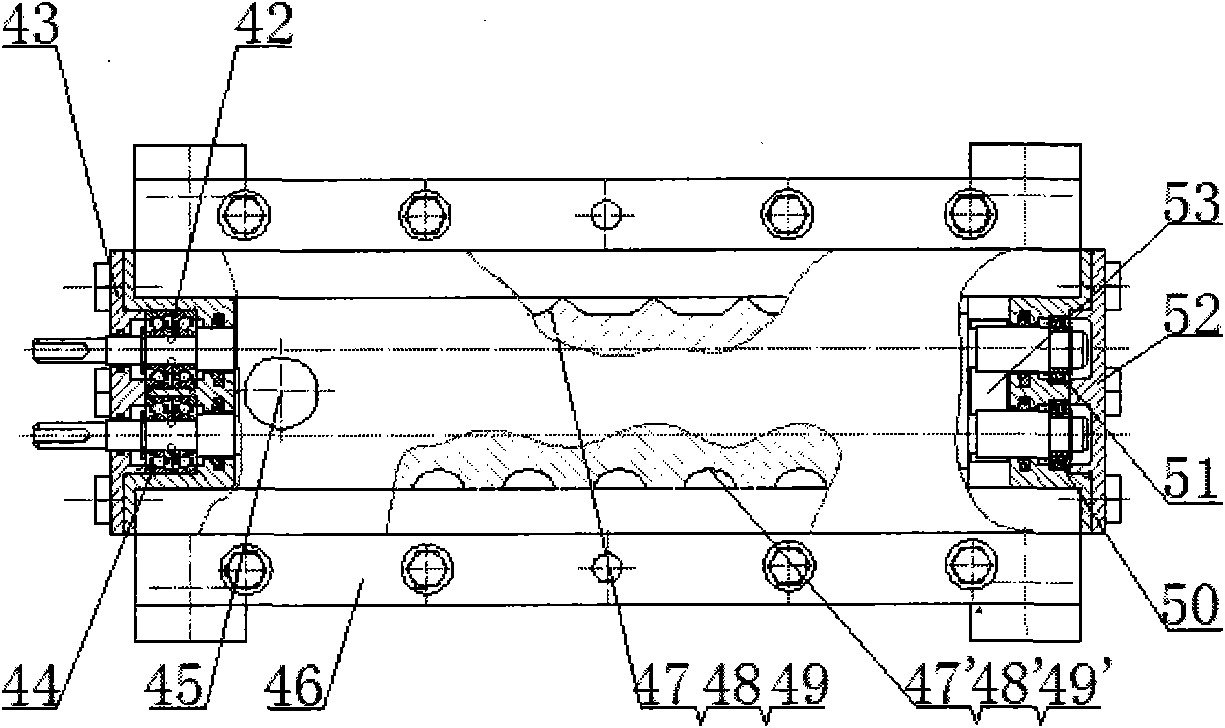

[0025] Adjust the 1:2 gear pinion gear 28 in the sliding gear set to the position of mating and meshing with the 1:2 gear gear gear 27 through the shift lever, and finally transmit the power to the second gear with a gear ratio of 1:2. The male screw rotor 48 and the second female screw rotor 48', the material enters the kneader from the feed port 45 on the barrel 46, through the rotation of the twin-screw rotors, and after being fully stirred and extruded, the material is discharged from the discharge port 53 discharge.

Embodiment approach 3

[0027] The 1:4 gear pinion gear 24 in the sliding gear set is adjusted to the position of mating and meshing with the 1:4 gear gear gear 22 through the shift lever, and finally the power is transmitted to the third gear gear with a gear ratio of 1:4. The male screw rotor 49 and the third female screw rotor 49', the material enters the kneader from the feed port 45 on the barrel 46, through the rotation of the twin-screw rotors, and after being fully stirred and extruded, the material is discharged from the discharge port 53 discharge.

[0028] The invention can quickly replace different screw rotors according to different processing requirements, and greatly improves the production efficiency of the twin-screw kneading equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com