Dust-free fiber deep filtration filter element

A deep filtration and fiber technology, applied in the direction of filtration separation, dispersed particle filtration, mechanical equipment, etc., can solve the problems of reduced filtration efficiency, easily damaged filter membrane, low porosity and strength, etc., to reduce the passage resistance and air gap Large, effective filter area reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

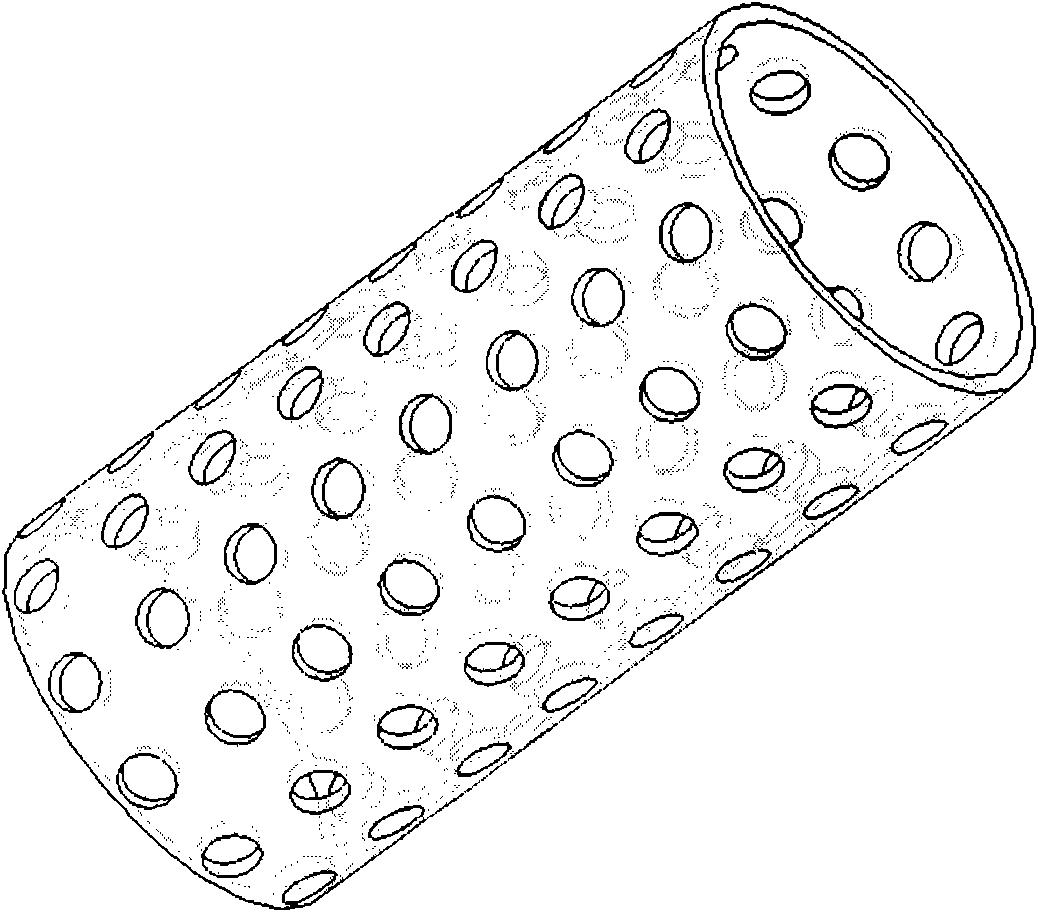

[0030] figure 1 It is a non-stick ash fiber depth filter element designed according to the above method, which is composed of a wound fiber bundle 1 and a porous cylinder 2.

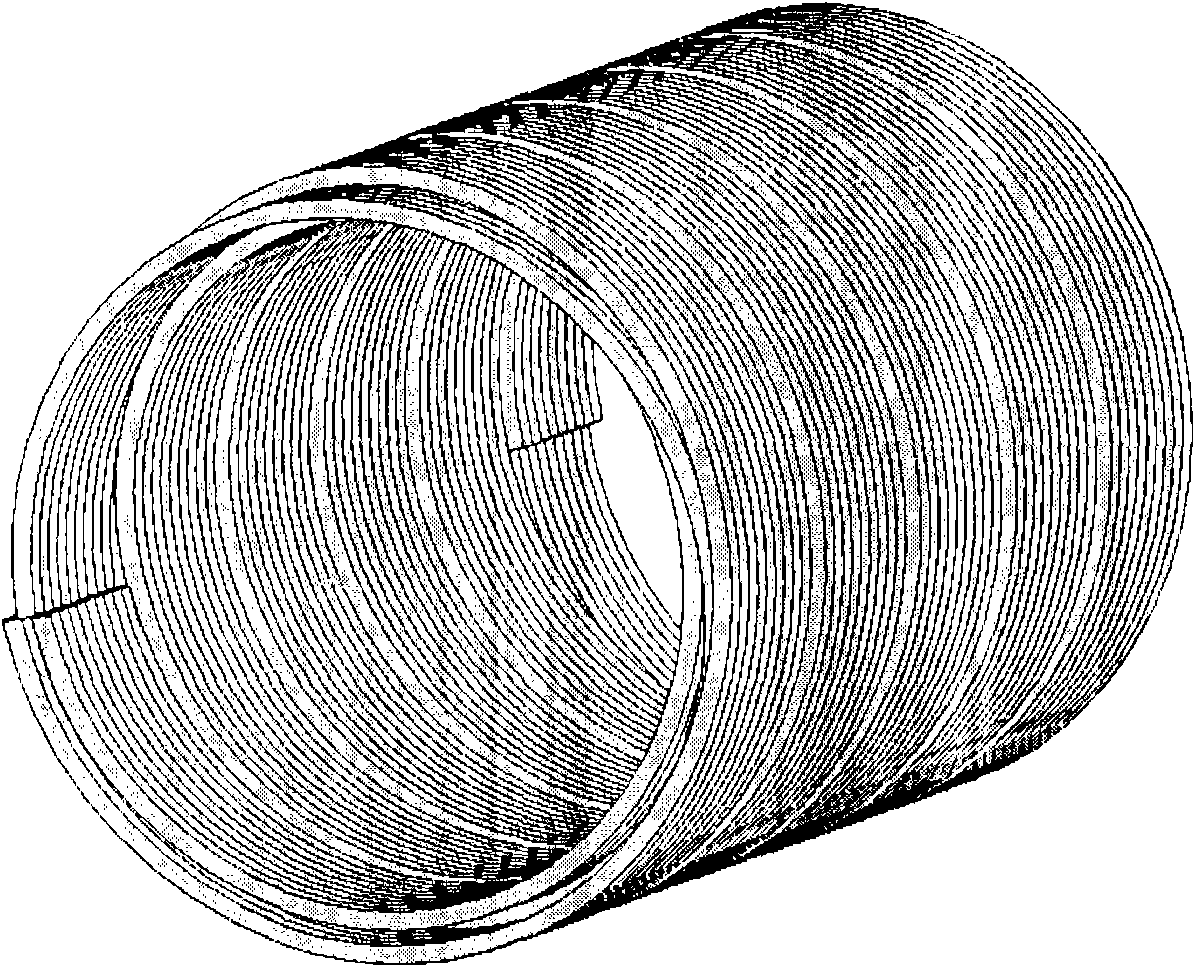

[0031] figure 2 is the porous cylinder 2, image 3 is the entangled fiber bundle 1 .

[0032] The fiber bundle 1 with dust-free performance is wound on a porous cylinder 2 to form a cylindrical filter element, and the air flows in from the periphery of the cylindrical filter element and flows out from the inner hole of the cylindrical filter element, or vice versa. Outflow from the inner hole.

[0033] In order to prevent the fiber bundle from spreading, the winding can be staggered into a flower shape; the periphery of the filter element can be cleaned with water or high-pressure airflow; the tightness and thickness of the winding layer depends on the filtration accuracy.

[0034] The dust-free performance fiber can be a material that reduces the surface energy by compounding a layer on the ordinar...

Embodiment 2

[0038] Figure 4 It is a kind of non-stick gray fiber depth filter element designed according to the above method, which is composed of fiber cloth 3 and porous cylinder 2. Weave the fiber bundle 1 with dust-free performance into fiber cloth 3, then wind the fiber cloth on the porous cylinder 2 to form a cylindrical filter element, the air flows in from the periphery of the cylindrical filter element, and the The inner hole of the filter element flows out, or vice versa, preferably the periphery flows in and the inner hole flows out. The weaving tightness of the fiber cloth and the thickness of the winding layer depend on the filtration accuracy.

[0039] The method of obtaining the dust-free performance fiber is the same as above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com