Flexible voltage nested battery module design

A technology for battery modules and battery packs, which is applied to secondary batteries, battery pack parts, battery boxes/coatings, etc. It can solve the problem of insufficient heat dissipation of battery modules, connection of multiple single modules, and lack of stable structure of battery modules And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

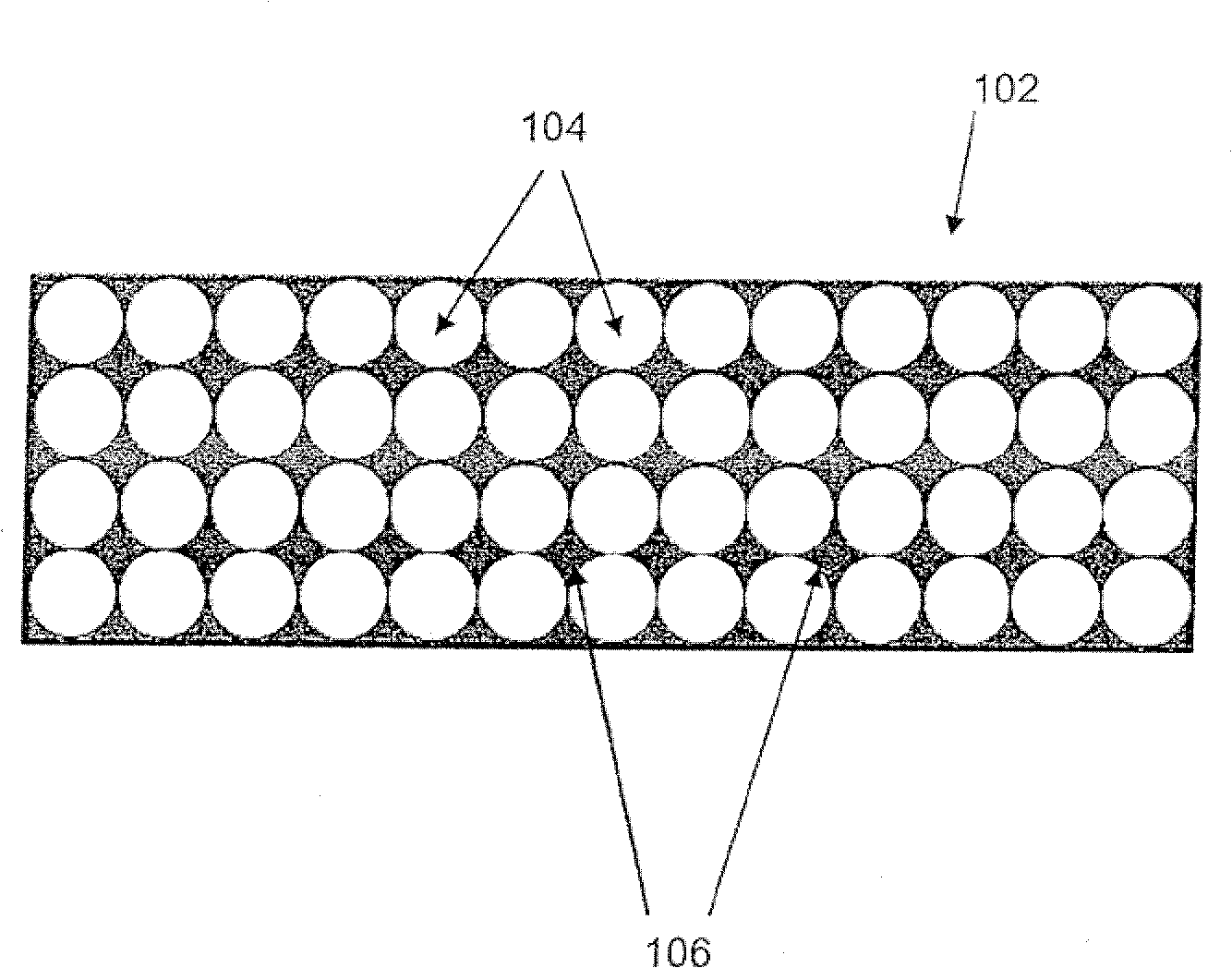

[0059] Aspects of the invention provide a flexible multi-voltage battery module having multiple cells nested together. According to different embodiments, battery cells in a module may be efficiently packaged and may utilize different configurations to provide different output voltages. Additionally, battery modules can be packaged together using an interlocking mechanism. Exemplary embodiments of the present invention also provide battery cells welded to bus bars in an efficient and robust manner.

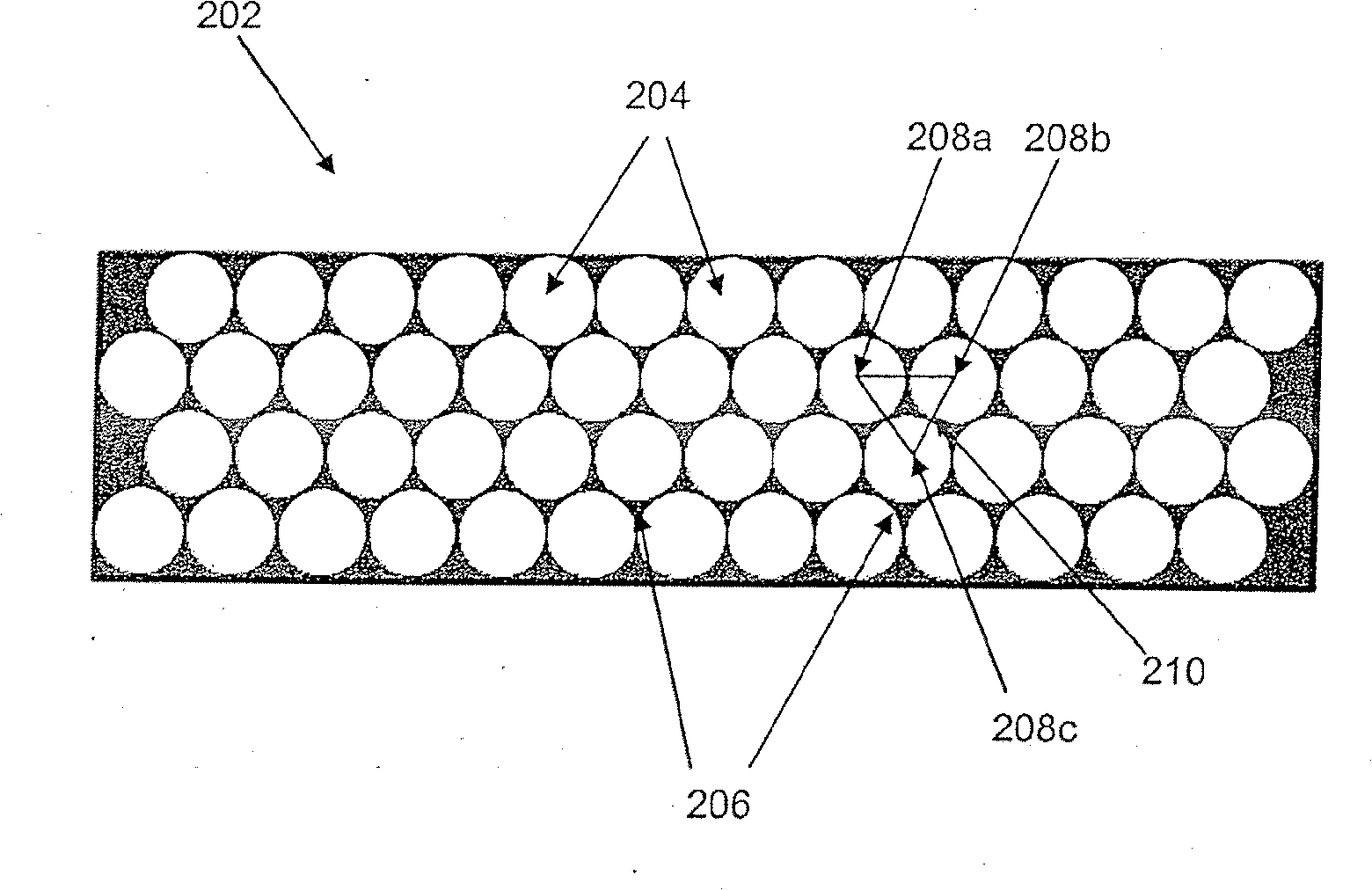

[0060] figure 2 is a top view showing the construction of battery cells 204 in a battery module 202 according to one or more exemplary embodiments of the present invention. As shown, cells 204 are arranged in a nested fashion such that centers of adjacent cells (eg, centers 208a, 208b, 208c) form an equilateral triangle (eg, triangle 210). In this way, the gap 206 between the battery cells is minimized. With this nested configuration, about 85% of the inter-module interspace,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com