Fan-shaped grater for foodstuffs

A friction device, fan-shaped technology, applied in the direction of applications, home appliances, kitchen appliances, etc., to avoid bending and improve the effect of stable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

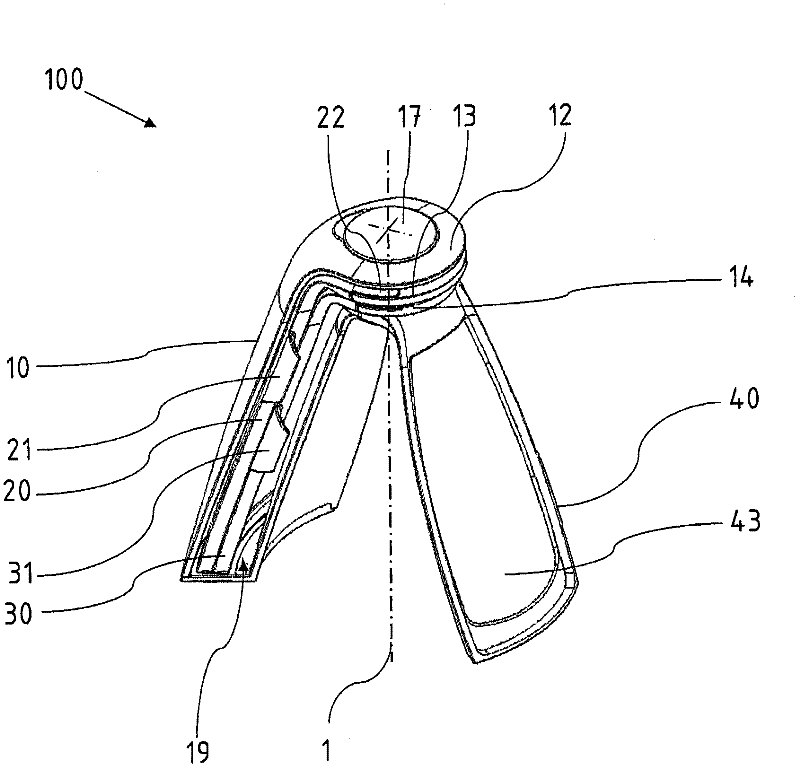

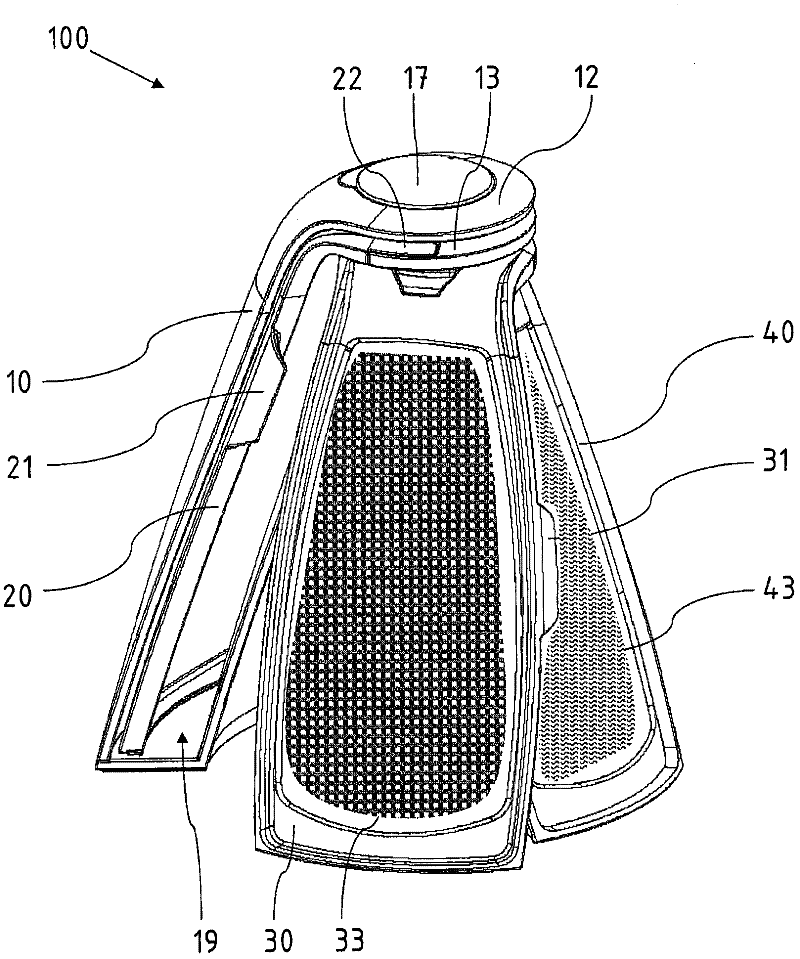

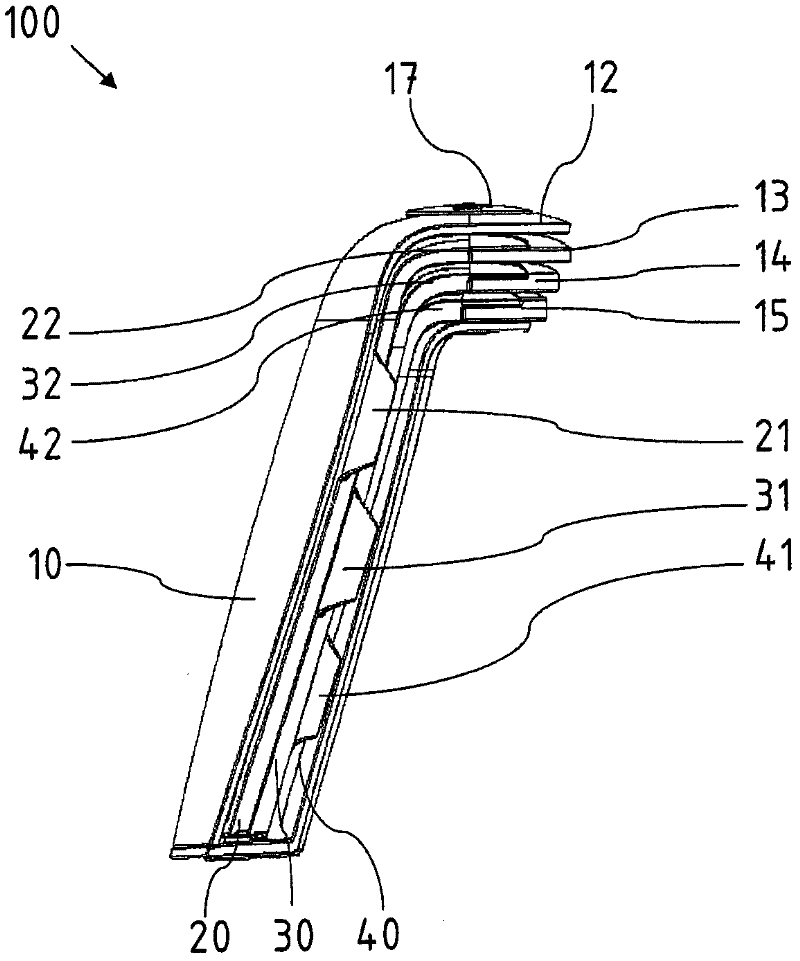

[0030] exist figure 1 100 shows a fan-shaped friction device 100 , which comprises an outer base element 10 which is curved in its upper region and merges into a head region 12 .

[0031] In the head region 22 of the first friction block 20 is formed a specially shaped head part 13 which, in the exemplary embodiment shown, has a non-visible receiving recess so that the pivot element 17 can be inserted there. A pivoting movement about the pivot axis 1 is thus achieved.

[0032] Below the head part 13 there is a further head part 14 for the second friction brake module 30 . The third friction block 40 is swiveled out and opposite the base element 10 , thus creating a parabolic profile and the fan-shaped friction block is free standing. The friction modules 20 and 30 remain in the receiving chamber 19 in the hollow base element 10 and can be swiveled out of the base element 10 by means of their grip tabs 21 , 31 . In the storage state, the friction modules 20 , 30 , 40 are thu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com