Electrophotographic photosensitive member, process cartridge, and electrophotographic apparatus

A technology of electrophotography and photosensitive member, which is applied to the equipment of electric recording technology using charge pattern, the electric recording technology of applying charge pattern, optics, etc., which can solve the problems of photosensitive member discharge breakdown and uneven charging, and achieve the purpose of suppressing The effect of image defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] The properties of the resin were measured or evaluated by the following methods.

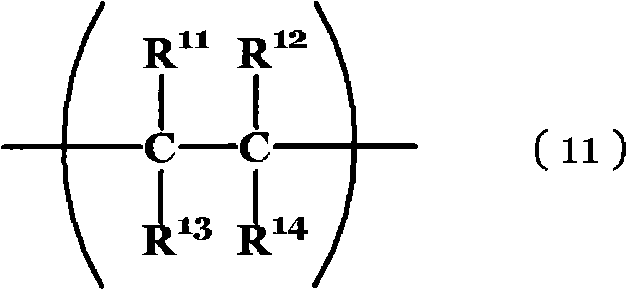

[0091] (1) Content of unit (A2) in polyolefin

[0092] The acid value of the polyolefin resin is measured in accordance with JIS K5407, and the content of unsaturated carboxylic acid (graft ratio) is determined from this value with the following equation.

[0093] Unit (A2) content (mass %)=(mass of grafted unsaturated carboxylic acid) / (mass of raw polyolefin resin)×100

[0094] (2) Composition of resin other than unit (A2)

[0095] The content of the components other than the unit (A2) was determined by using an analyzer (manufactured by Varian Technologies Japan Limited, 300 MHz) in o-dichlorobenzene (d4) at 120°C 1 H-NMR and 13 C-NMR analysis to determine. Considering the quantitative 13 C-NMR analysis was performed by using the gated decoupling method. The method of synthesizing the polyolefin resin is not limited to Production Example 1, and it can be obtained by using, for exa...

Embodiment 2

[0111] An electrophotographic photosensitive member was produced in the same manner as in Example 1 except that the polyolefin resin used in the conductive layer in Example 1 was changed to Polyolefin Resin O-2. Resin O-2 is formed of a repeating structural unit (A1) obtained by copolymerizing polyethylene, a repeating structural unit (A2) obtained by copolymerizing maleic anhydride, and a repeating structural unit (A3) obtained by copolymerizing ethyl methacrylate, and its It has a ratio "(A1) / (A2) / (A3)" of 80.00 / 2.00 / 18.00 (mass %). This electrophotographic photosensitive member was evaluated in the same manner as in Example 1.

Embodiment 3

[0113] An electrophotographic photosensitive member was produced in the same manner as in Example 1 except that the polyolefin resin used in the conductive layer in Example 1 was changed to Polyolefin Resin O-3. Resin O-3 is formed of a repeating structural unit (A1) obtained by copolymerizing ethylene, a repeating structural unit (A2) obtained by copolymerizing maleic anhydride, and a repeating structural unit (A3) obtained by copolymerizing ethyl acrylate, and It has a ratio "(A1) / (A2) / (A3)" of 91.99 / 0.01 / 8.00 (mass%). This electrophotographic photosensitive member was evaluated in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com