Non-contact two-dimensional gantry measurement workstation

A non-contact measurement and non-contact technology, applied in the field of measurement tools, can solve the problems of large manual reading error, poor detection tool accuracy, manual reading error, etc., to achieve smooth motion, improve measurement accuracy, and improve the effect of motion accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

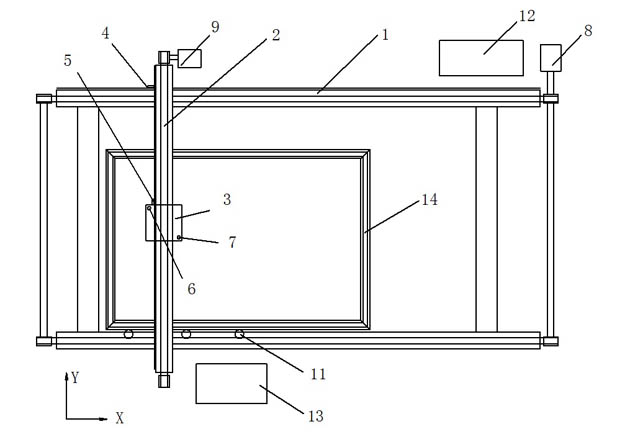

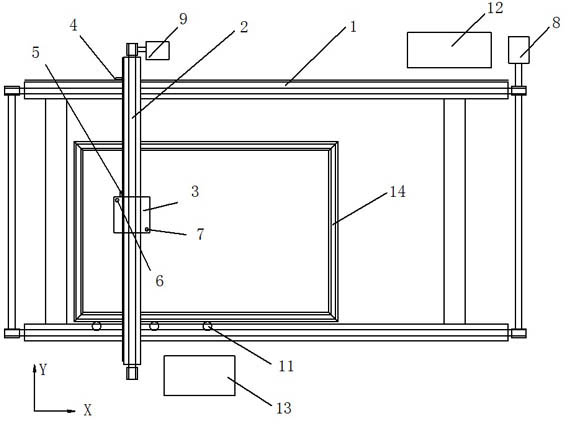

[0027] As shown in the figure, a gantry non-contact two-dimensional measurement workstation includes: a bed 1, a large gantry 2, a small gantry 3, a non-contact measuring device, a transmission device and a controller; the non-contact measuring device includes: X-direction magnetic grid sensor 4, Y-direction magnetic grid sensor 5, non-contact measuring head A 6, non-contact measuring head B 7; transmission device includes: large gantry transmission motor 8 and small gantry transmission motor 9; controller It includes: electrical control cabinet 12 and control computer 13; above-mentioned bed 1, large gantry 2 and small gantry 3 are all provided with guide rails.

[0028] The connection relationship of the above components is as follows:

[0029] There is a guide rail in the X direction of the bed 1, and the large gantry 2 is installed on the guide rail on the bed 1, and can reciprocate along the X direction, and the large gantry 2 is perpendicular to the X direction; the Y of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com