Heat-conducting piece

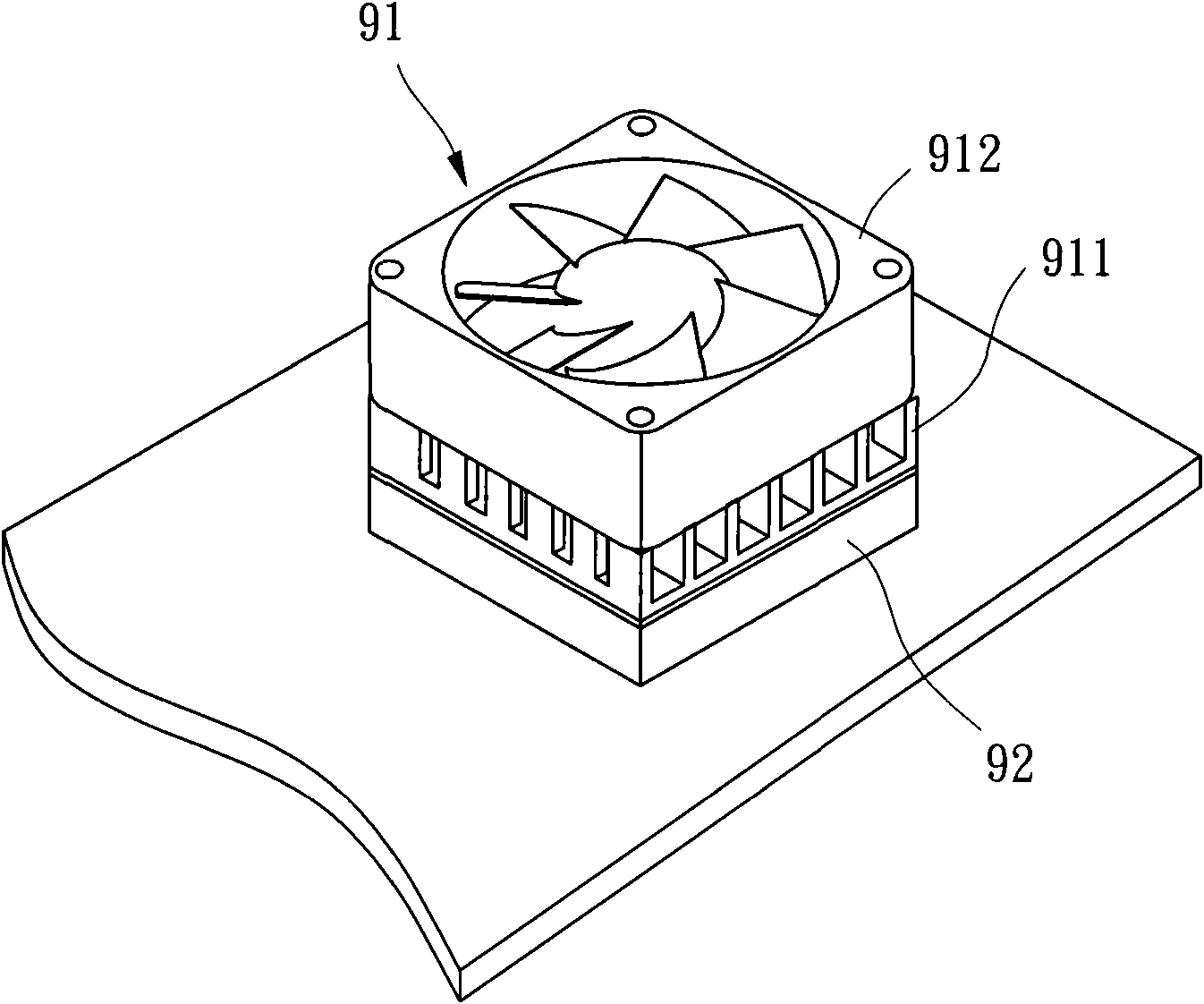

A technology of guide and heat dissipation surface, applied in the direction of laminated components, heat exchange equipment, lighting and heating equipment, etc., can solve the problem that the assembly height is not easy to reduce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

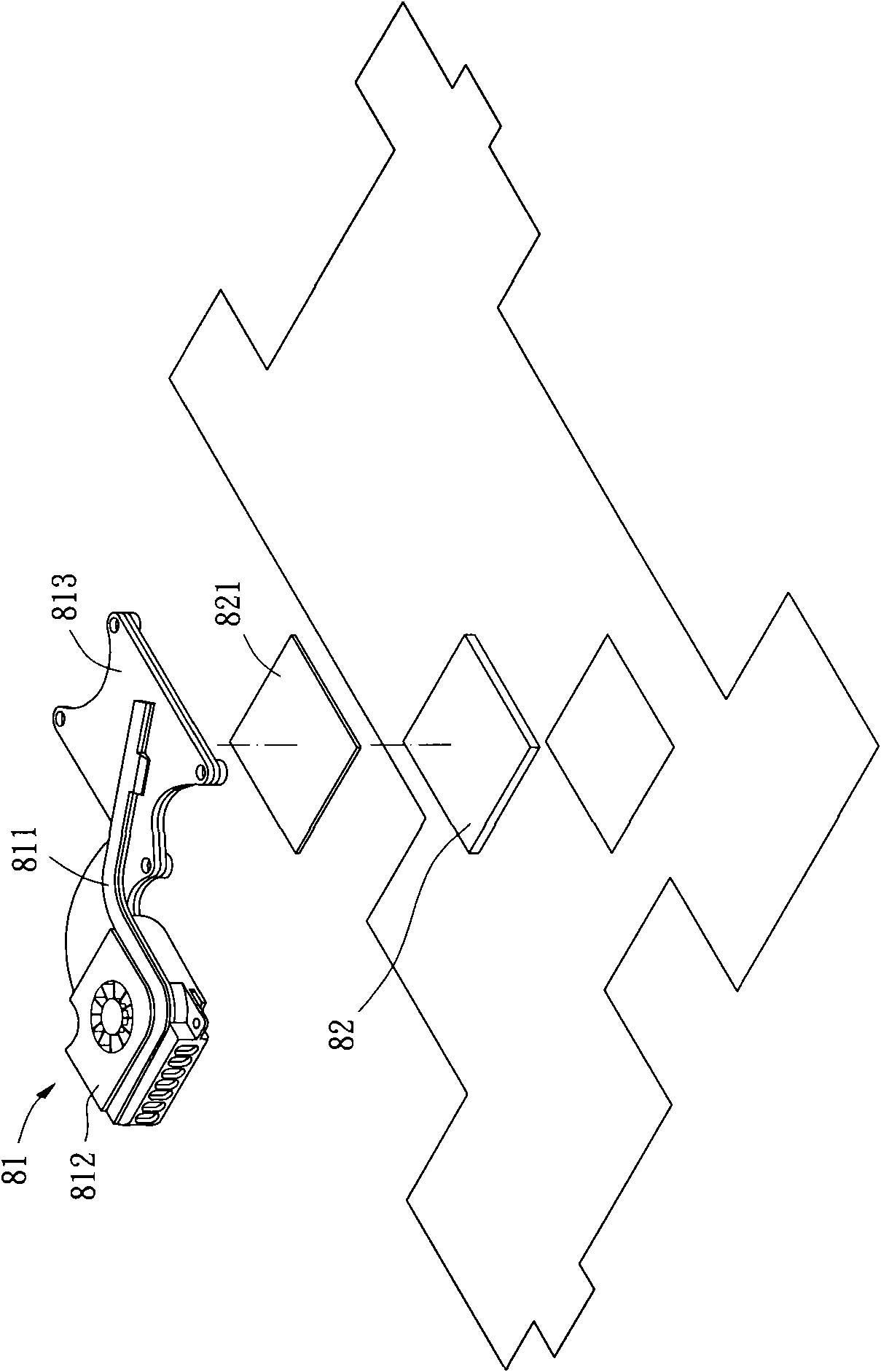

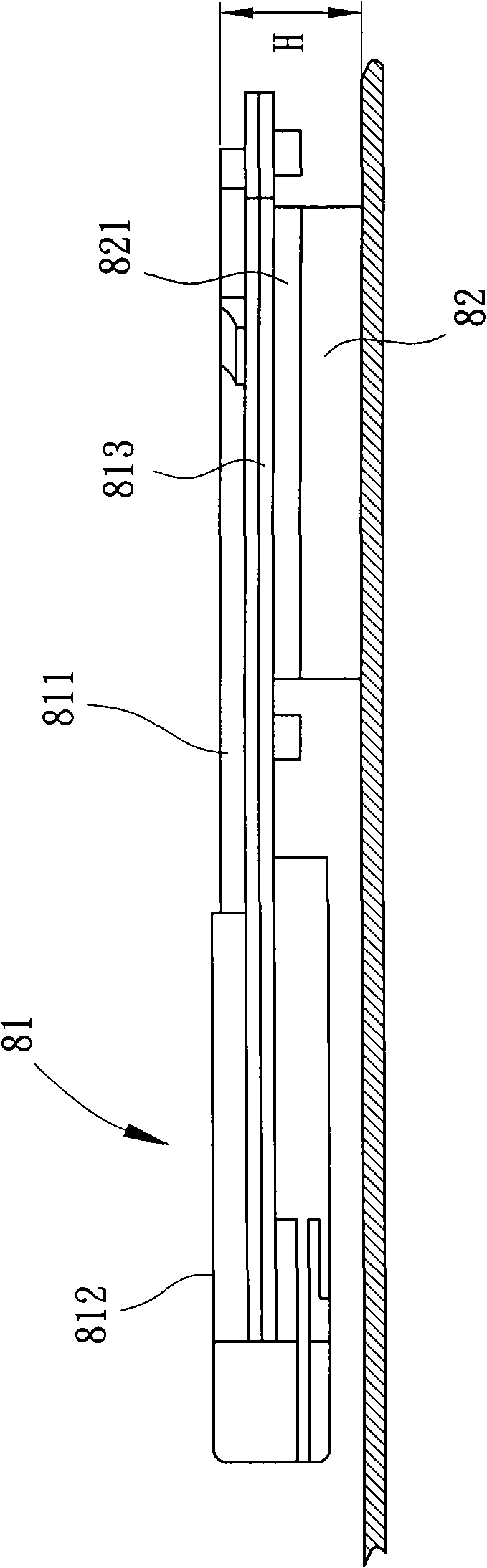

[0034] Please refer to Figure 5 As shown, the heat conducting member 1 of the first embodiment of the present invention at least includes a heat conducting sheet 11 , an extending sheet 12 and a connecting sheet 13 . The heat conducting sheet 11 has a first heat dissipation surface 111; the extension sheet 12 has a second heat dissipation surface 121; the opposite ends of the connecting sheet 13 are respectively provided with a first joint portion 131 and a second joint portion 132, the first joint portion 131 and a second joint portion 132 respectively. A joint portion 131 connects one peripheral edge of the heat conduction sheet 11, and the second joint portion 132 connects one side peripheral edge of the exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com