Tower foot anchoring structure for assembling tower and tower building method

An anchoring structure and tower foot technology, applied in construction, bridge construction, erection/assembly of bridges, etc., can solve the problems of affecting the construction progress, large amount of materials, harsh environmental requirements, etc., to increase the overall strength, the construction process is simple, shorten the The effect of the construction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

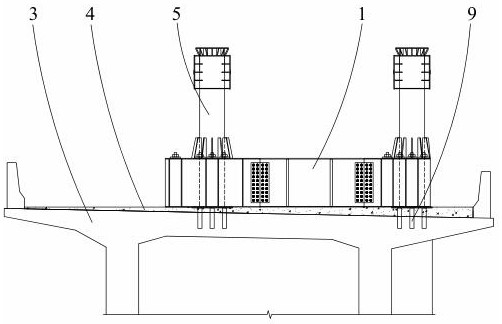

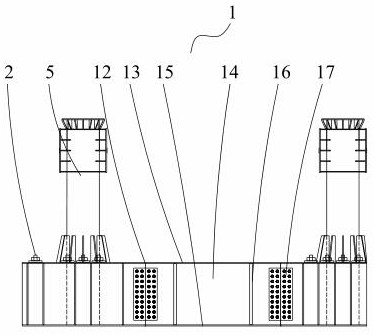

[0046] Such as Figure 1-Figure 13 As shown, a tower foot anchoring structure for an assembled tower in this embodiment is suitable for the tower foot anchoring of towers in the bridge construction process. The prestressed steel strand 2 is pre-embedded vertically in block 3 of 0#, and a pre-embedded pipe 41 is installed on block 3 of 0# corresponding to the column at the foot of the tower. The bottom of the pre-embedded pipe 41 is pre-embedded in block 3 of 0#. Extend 10-20cm, the beam body member 1 is placed on the top of the embedded pipe 41, anchored and fixed above the 0# block 3 through the prestressed steel strand 2, and the pipe body 5 is vertically arranged on the beam body member 1, and the pipe body 5 It is used to dock with the tower foot column.

[0047] In the tower foot anchorage structure for an assembled tower in this embodiment, prestressed steel strands 2 and pre-embedded pipes 41 are pre-embedded in the 0# block 3 reinforcement cage before the 0# block 3 i...

Embodiment 2

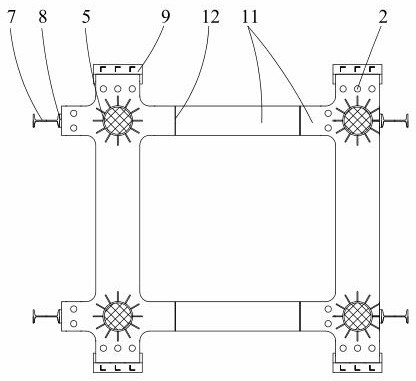

[0056] Such as Figure 1-Figure 13 As shown, a tower foot anchoring structure for an assembled tower in this embodiment has the same structure as that of Embodiment 1, the difference is that it also includes a number of limiting columns 7, which are pre-embedded in the top surface of 0# block 3 at least 30cm, protrude 0# block 3 at least 50cm, all limit columns 7 are arranged around beam body member 1, the distance between each limit column 7 and beam body member 1 is no more than 2cm, each limit column 7 and beam body The components 1 are abutted by setting embedded blocks 8 .

[0057] In the tower foot anchorage structure for an assembled tower in this embodiment, the limit column 7 is a vertically arranged I-beam, and the closed surface of the I-beam fits the side wall of the beam member 1, preventing the beam member 1 from The top surface of 0# block 3 has lateral slippage.

[0058] Specifically, before the 0# block 3 is poured, the limit column 7 is bound and fixed on t...

Embodiment 3

[0061] Such as Figure 1-Figure 13 As shown, a tower foot anchoring structure for an assembled tower in this embodiment has the same structure as Embodiment 1 or Embodiment 2, the difference is that it also includes a number of shear keys 9, and each shear key 9 includes arranging A number of L-shaped steels, the top of the shear key 9 is connected to the bottom of the beam member 1, the bottom is pre-embedded in the 0# block 3, and the shear key 9 is set at the position where the prestressed steel strand 2 passes through the top surface of the 0# block 3 outside.

[0062] In the tower foot anchorage structure for an assembled tower in this embodiment, the shear keys are six L-shaped steels arranged in double rows, connected as a whole by the top steel plate, and attached to the bottom surface of the beam member 1 by the top steel plate, and located at The prestressed steel strand 2 passes through the outside of the top surface of the 0# block 3 .

[0063] Specifically, befo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com