Auxiliary supporting structure for planetary mechanism assembly of planetary transmission pair speed changer of automobile speed changer

A technology of automobile transmission and auxiliary transmission, applied in the field of automobile transmission, can solve problems such as manufacturing, use, and service cost constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

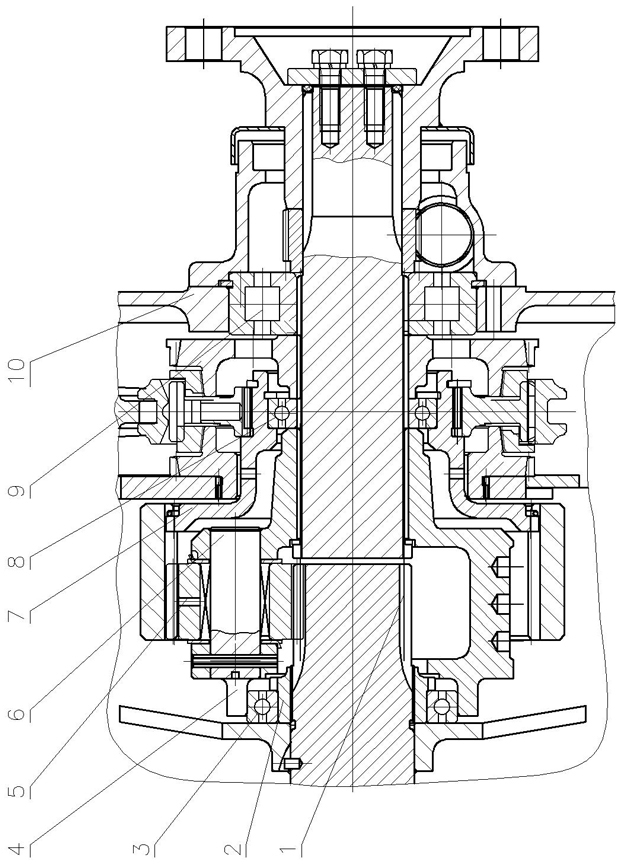

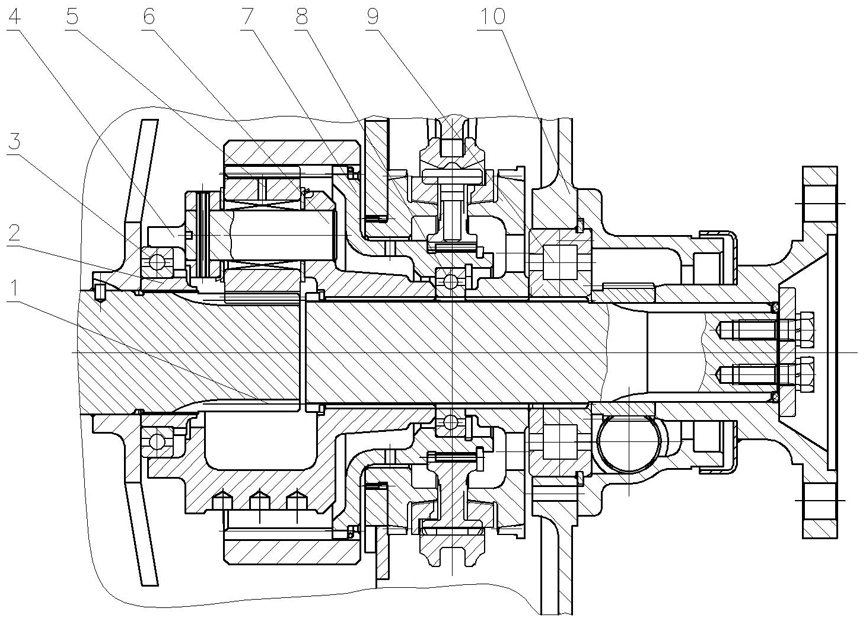

[0009] As shown in the figure, the inner ring of the auxiliary support bearing 3 of the present invention is fixed on the lock nut 2, and the outer ring is mounted on the planet carrier 4 in the planetary mechanism with clearance fit, and there is a certain amount of floating. The auxiliary transmission input gear (sun gear) 1 is directly integrated with the second shaft of the main transmission (or fixed on the second shaft of the main transmission through splines); in the planetary mechanism, the planetary gear 5 is vacantly sleeved on the planet through a needle bearing. On the wheel shaft 6, the planet wheel shaft 6 is directly supported on the planet carrier 4, one end of the planetary mechanism assembly is supported on the rear housing 10 through the cylindrical roller bearing 9, and the other end is meshed with the sun gear 1 through the planetary wheel 5; at the same time, the support seat 7 floats On the deep groove ball bearing 8, there is a gap between the outer ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com