Method for reducing noises by adjusting yaw braking forces of wind turbine

A yaw braking and force adjustment technology, applied in the control of wind turbines, wind turbines, machines/engines, etc., can solve the problems of large pressure loss along the way, unable to guarantee the braking force phase of the brake chuck, etc., to reduce noise , reduce wear and damage to the transmission mechanism, and improve the efficiency of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

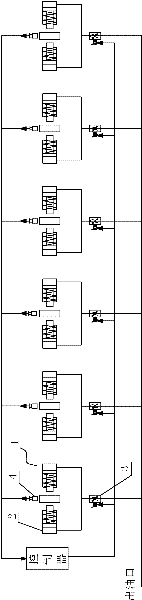

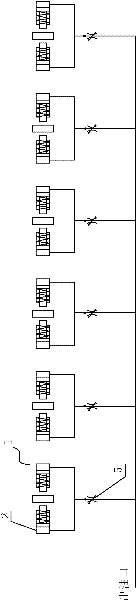

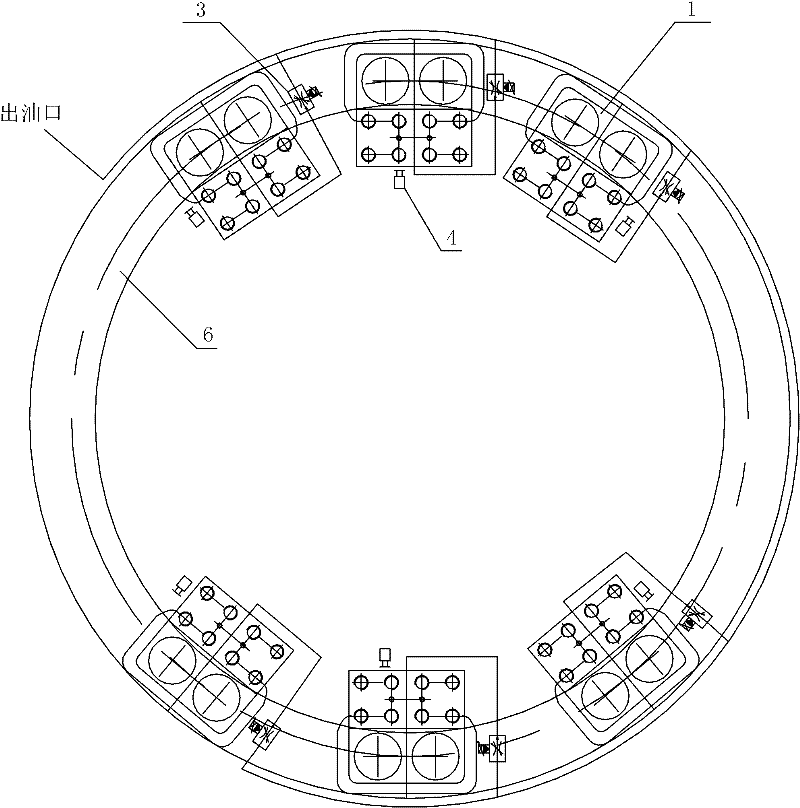

[0021] Refer to attached figure 1 to attach image 3 As shown, a wind turbine yaw braking force adjustment noise reduction method, the oil outlet of the oil supply system is respectively connected with the rodless cavity of the oil cylinder 2 in the six brake chucks 1, and the oil outlet of the oil supply system An electro-hydraulic proportional throttle valve 3 is connected in series on the hydraulic pipeline connected between the port and each brake chuck 1 oil cylinder, and a sound intensity sensor 4 is installed on each brake chuck 1 at the same time.

[0022] During the yaw braking process of the wind turbine, the controller monitors the sound intensity sensor 4 on one of the hydraulic chucks 1, and obtains the noise signal output by the sound intensity sensor 4. According to the obtained monitoring information, the controller sends a signal to the hydraulic chuck The electro-hydraulic proportional throttle valve 3 on the disc 1 sends a control signal to control and adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com