Heat pump clothes dryer and control method thereof

A control method and technology for clothes dryers, which are applied to household clothes dryers, washing devices, textiles, and papermaking, etc., and can solve the problems of poor efficiency and decline of clothes dryers, and constant drying efficiency of clothes dryers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

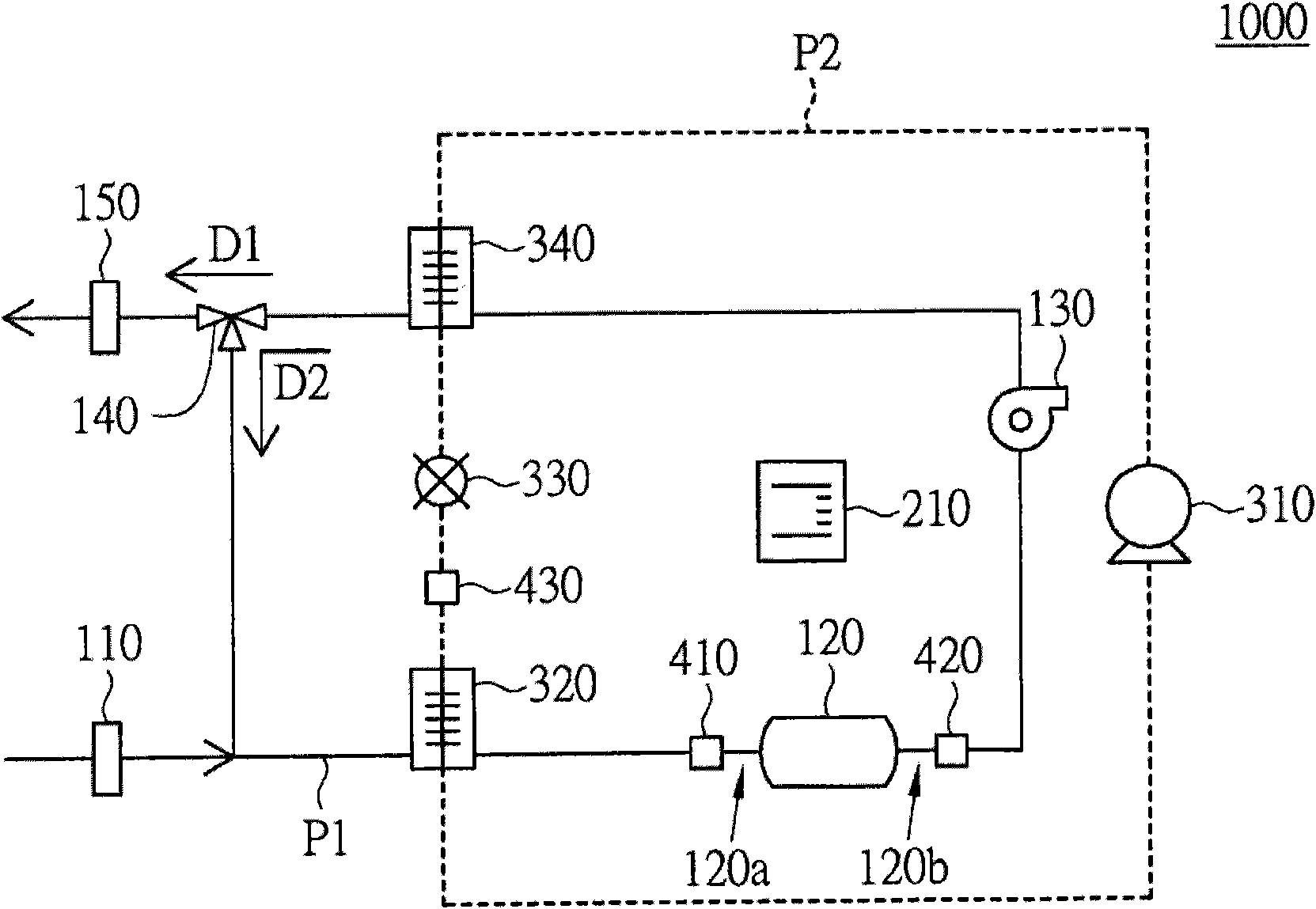

[0038] Please refer to figure 1 , which shows a schematic diagram of the heat pump clothes dryer 1000 of the first embodiment. The heat pump dryer 1000 of this embodiment includes an air supply unit 110, an exhaust unit 150, a drying chamber 120, a circulation fan 130, a switching unit 140, a control unit 210, a compression unit 310, a condenser unit 320 , an expansion unit 330 , an evaporation unit 340 , a first measurement unit 410 , a second measurement unit 420 and a third measurement unit 430 . A gas passage P1 connects the air supply unit 110 , the first measurement unit 410 , the drying chamber 120 , the second measurement unit 420 , the circulation fan 130 , the switch unit 140 and the exhaust unit 150 . A refrigerant channel P2 is connected to the compression unit 310 , the condensation unit 320 , the third measurement unit 430 , the expansion unit 330 and the evaporation unit 340 .

[0039] The air supply unit 110 is used for providing an air into the heat pump clo...

no. 2 example

[0068] Please refer to Figure 4 , which shows a schematic diagram of the heat pump clothes dryer 2000 of the second embodiment. The difference between the heat pump dryer 2000 of this embodiment and the heat pump dryer 1000 of the first embodiment is that the heat pump dryer 2000 of this embodiment uses the cooling unit 350 and the switching unit 360 to improve the overheating of the refrigerant.

[0069] The cooling unit 350 is used to dissipate the condensed refrigerant. The heat dissipation unit 350 of this embodiment may adopt a passive heat sink with natural convection as the heat dissipation mechanism, for example, a heat sink with enlarged heat dissipation fins. Alternatively, the heat dissipation unit 350 of this embodiment may also be an active heat sink with a convection fan installed and forced convection as the heat dissipation mechanism.

[0070] The switch unit 360 is used to switch the condensed refrigerant to flow through the cooling unit 350 first and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com